Method for stabilizing palladium catalyst by montmorillonite

A palladium catalyst and montmorillonite technology, applied in the field of montmorillonite-stabilized palladium catalysts, can solve the problems of low oxygen reduction activity, poor stability and the like, and achieve the effects of high oxygen reduction activity, accelerated transfer, and excellent oxygen reduction catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

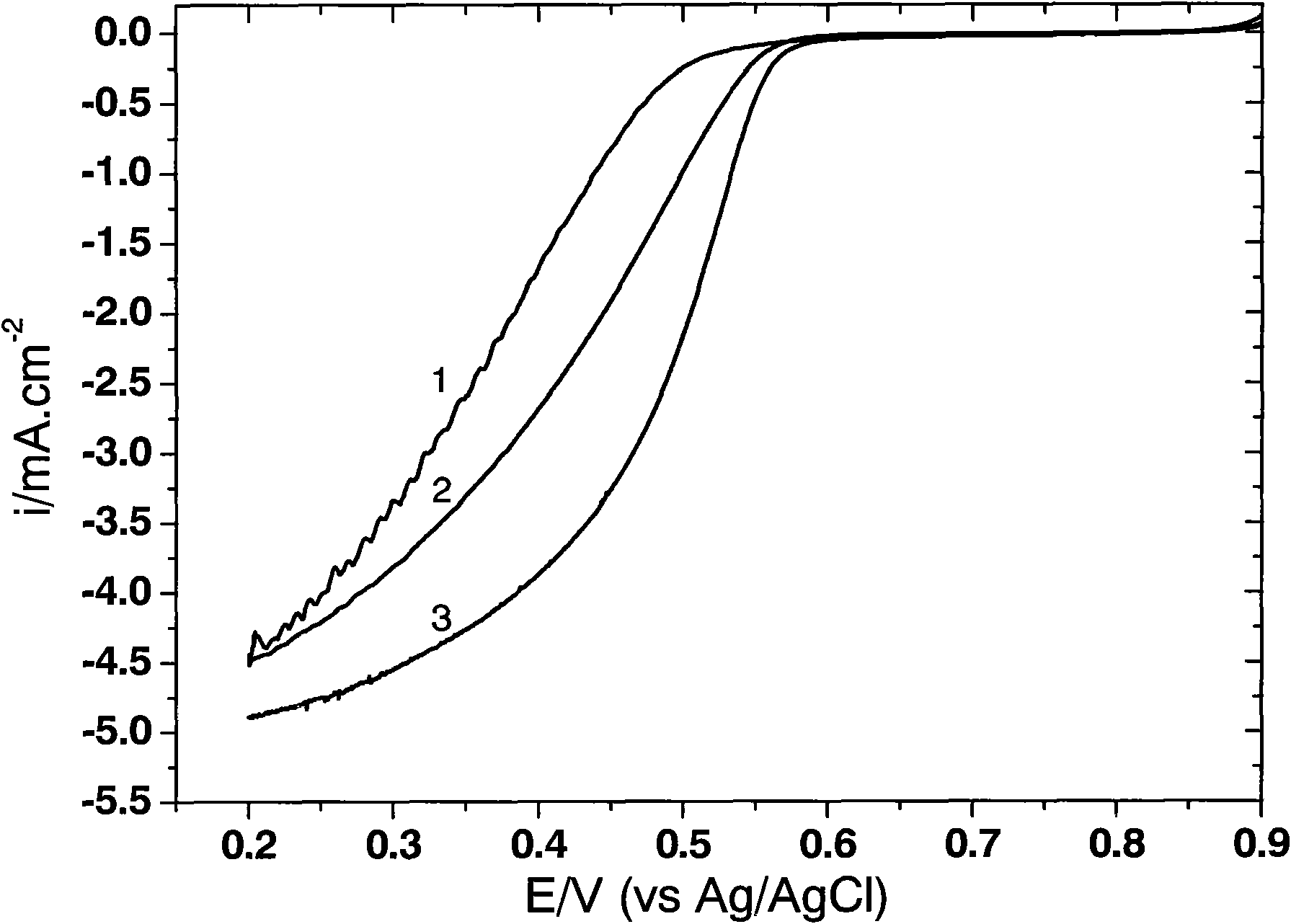

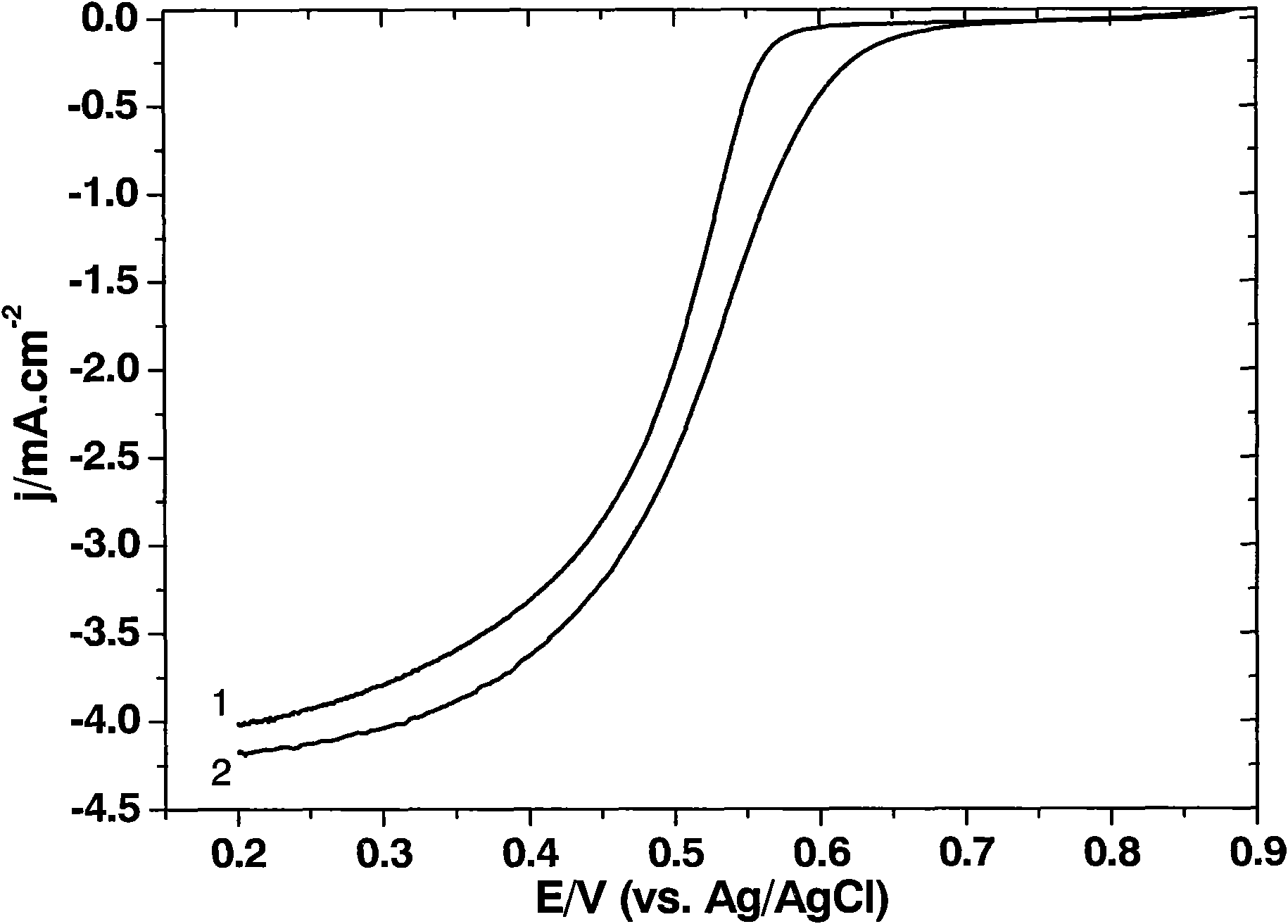

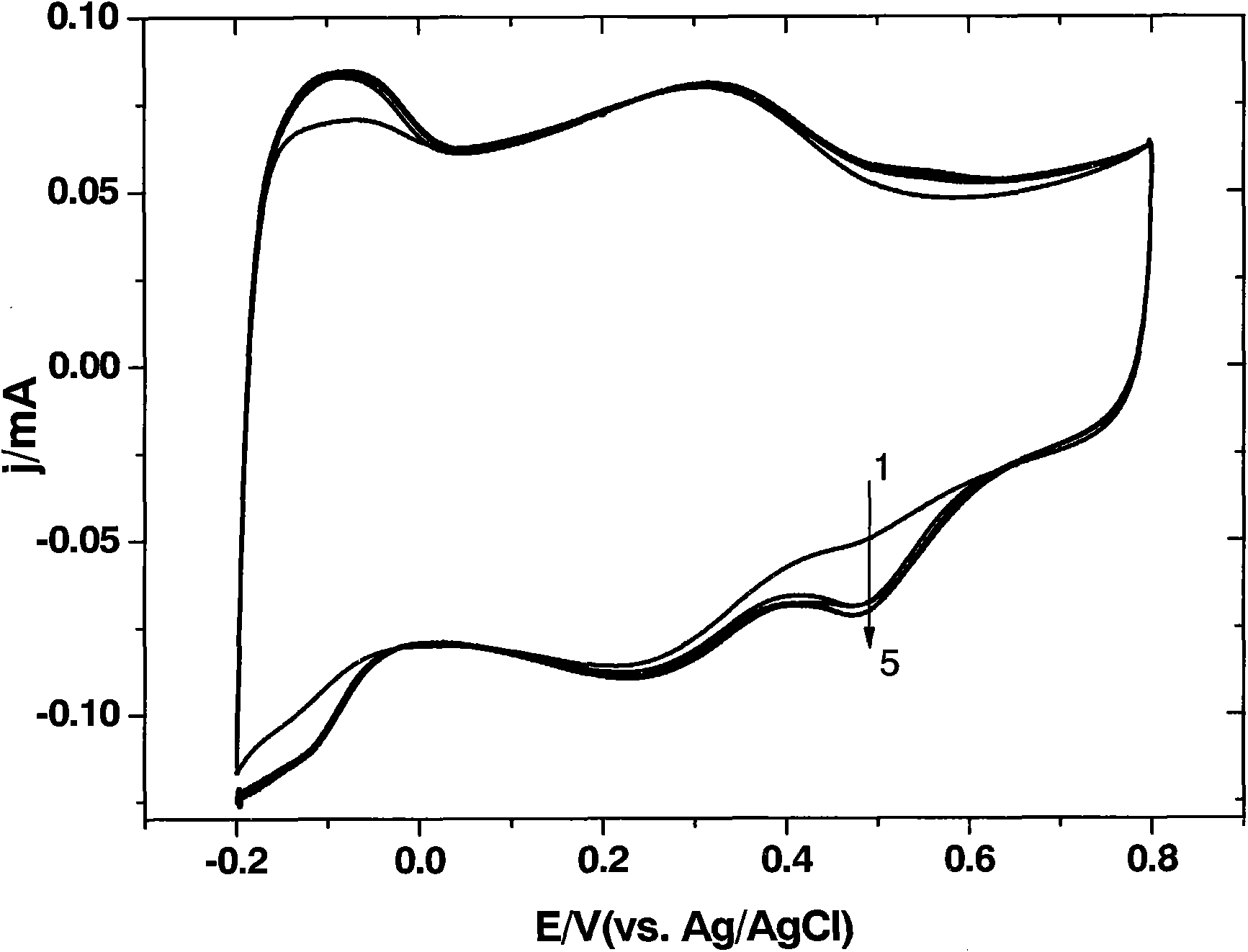

Examples

Embodiment 1

[0043] The concrete steps of a kind of method of montmorillonite stable palladium catalyst are as follows:

[0044] (1) Organic cationic modification of montmorillonite

[0045] Take sodium montmorillonite and cetyltrimethylammonium bromide according to the mass ratio of sodium montmorillonite: hexadecyltrimethylammonium bromide is 1: 0.5; Add deionized water at 60°C, and ultrasonically stir for 30 minutes to form a sodium-montmorillonite suspension with a mass concentration of 0.05 g / ml; Add it to the above sodium-based montmorillonite suspension, stir ultrasonically at 60°C for 20 minutes, then heat and reflux at 100°C for 24 hours, cool to 60°C, and finally vacuum filter, wash with deionized water, and dry And the organic cationic modified montmorillonite is obtained after grinding.

[0046] (2) Preparation of perfluorosulfonic acid resin intercalation organic cation-modified montmorillonite suspension

[0047] Organic cationic modified montmorillonite obtained by step (...

Embodiment 2

[0057] The concrete steps of a kind of method of montmorillonite stable palladium catalyst are as follows:

[0058] Step (1) is the same as step (1) in Example 1.

[0059] (2) Preparation of perfluorosulfonic acid resin intercalation organic cation-modified montmorillonite suspension

[0060] Organic cationic modified montmorillonite obtained by step (1): the mass ratio of perfluorosulfonic acid resin is 1: 0.1. Weigh organic cationic modified montmorillonite and perfluorosulfonic acid resin, wherein perfluorosulfonic acid resin The mass concentration of the solution is 5%; then the organic cation-modified montmorillonite is added to ethanol, ultrasonically oscillated for 40 minutes, and stirred at 60°C for 3 hours to disperse evenly to form an organic cation-modified montmorillonite with a mass concentration of 0.03g / ml Montmorillonite suspension; then add perfluorosulfonic acid resin solution to the above suspension, stir at 60°C for 12 hours, and cool to room temperature t...

Embodiment 3

[0070] The concrete steps of a kind of method of montmorillonite stable palladium catalyst are as follows:

[0071] Step (1) is the same as step (1) in Example 1.

[0072] (2) Preparation of perfluorosulfonic acid resin intercalation organic cation-modified montmorillonite suspension

[0073]Organic cationic modified montmorillonite obtained by step (1): the mass ratio of perfluorosulfonic acid resin is 1: 0.3. Weigh organic cationic modified montmorillonite and perfluorosulfonic acid resin, wherein perfluorosulfonic acid resin The mass concentration of the solution is 5%; then the organic cation-modified montmorillonite is added to isoprene glycol, ultrasonically oscillated for 40 minutes, and stirred at 70°C for 1 hour to disperse evenly to form an organic compound with a mass concentration of 0.05g / ml. Cationic modified montmorillonite suspension; then add perfluorosulfonic acid resin solution to the above suspension, stir at 70°C for 5 hours, and cool to room temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com