Modified rubber and method for producing the same

A technology of modified rubber and manufacturing method, applied in the field of modified rubber, which can solve the problems of reduced air-tightness, unfavorable atomic economy, and limited use, and achieve the effect of excellent air-tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

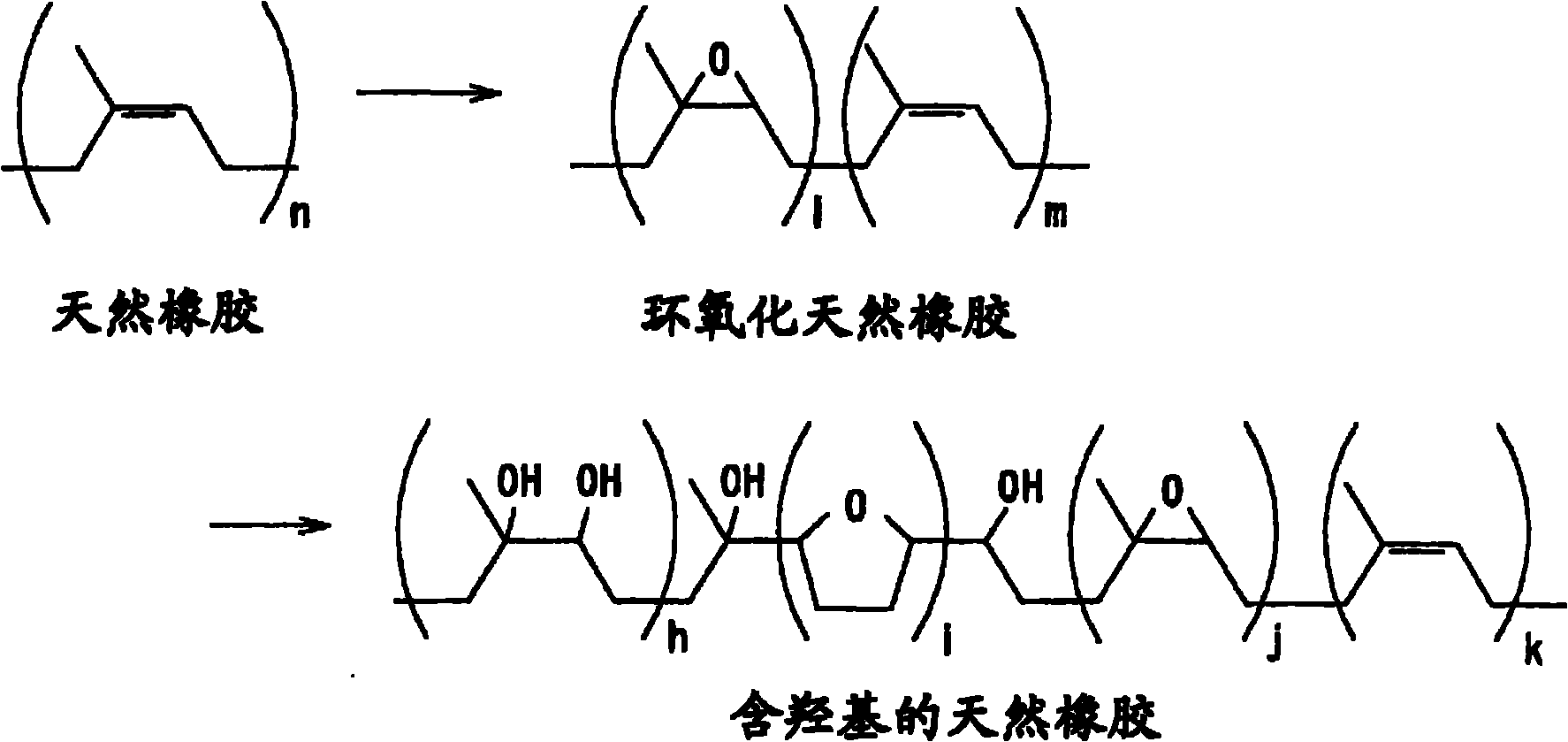

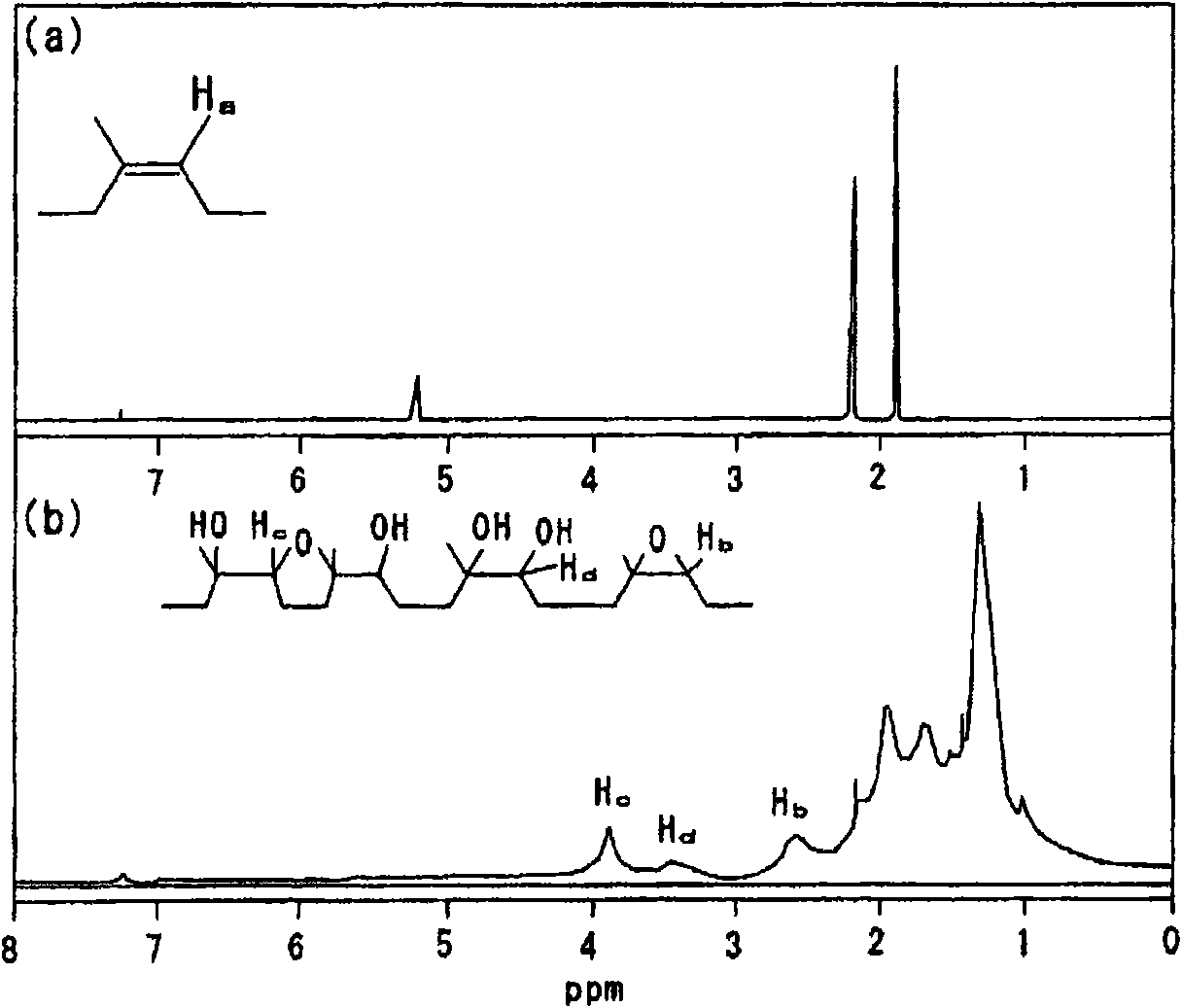

[0050] figure 1 The structure of the modified rubber according to an example of the present invention is shown. The modified rubber should be called hydroxyl-containing natural rubber, which is produced from natural rubber by epoxidizing natural rubber. The double bonds contained in each isoprene unit are all converted into hydroxyl, epoxy, and furan rings. . Hereinafter, instead of a detailed description of the configuration, a method for producing the modified rubber will be described.

[0051]

[0052] With respect to 100 mass parts of commercially available high ammonia natural rubber latex (30 mass % solid content), add 1.0 mass parts sodium lauryl sulfate and 0.1 mass parts urea, fully stir it and make it dissolve, then stand at room temperature for 1 Hour. It should be noted that urea was added to denature proteins.

[0053] Centrifugation was performed to remove the supernatant, and the resulting paste was mixed with a 1% by mass sodium lauryl sulfate aqueous sol...

Embodiment 2

[0061] 70 parts by mass of peracetic acid was added to 10 parts by mass of solid content of the deproteinized natural rubber latex formed in the same manner as in Example 1, and 5 parts by mass of isopropyl alcohol (IPA) was added simultaneously, stirred and mixed, and left to stand at room temperature for 16 hours . Thereafter, ammonia water was added for neutralization, and washing was repeated several times by centrifugation using distilled water. It was then dried under vacuum to formulate a modified rubber.

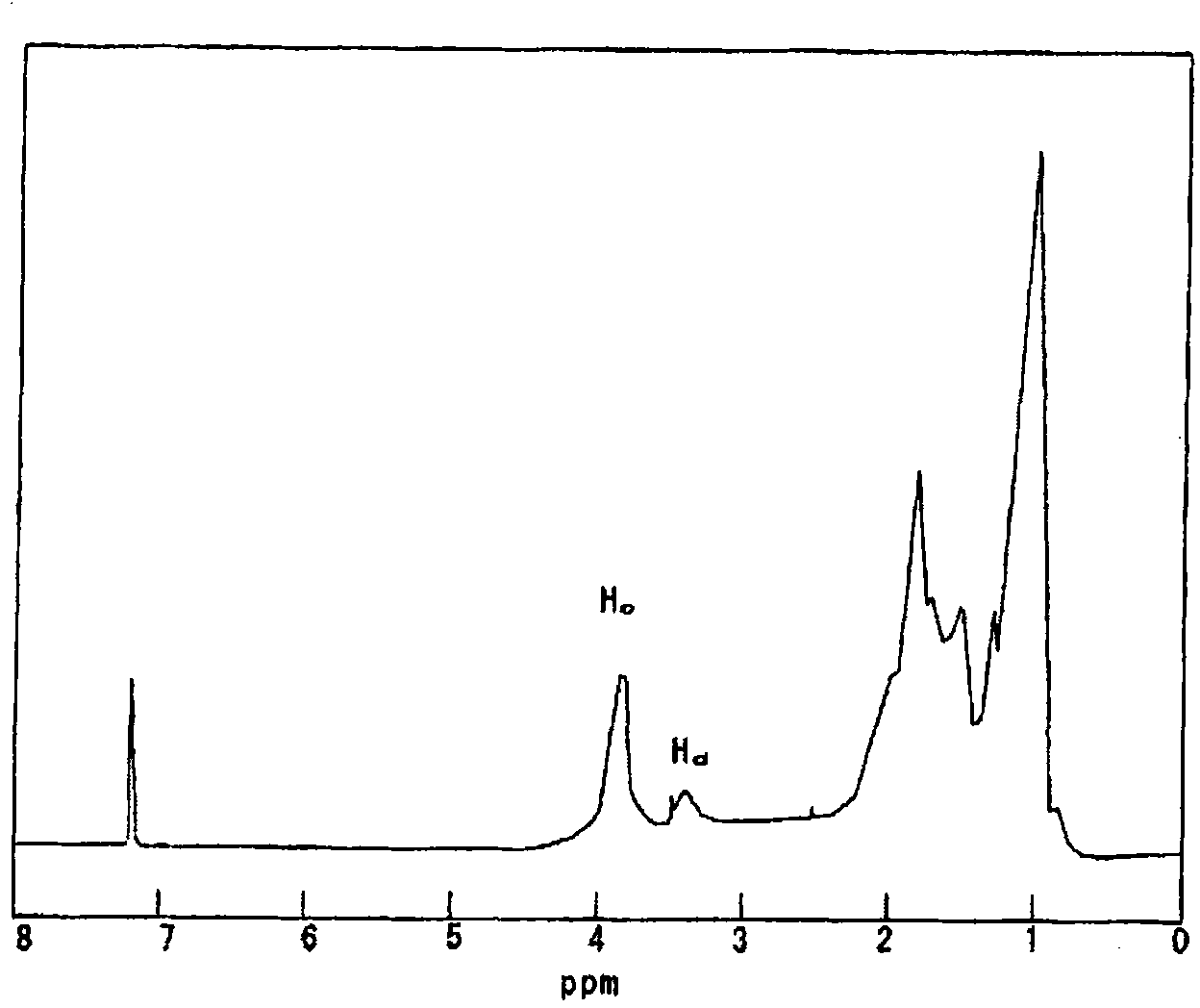

[0062] The NMR spectrum of the resulting modified rubber is shown in image 3 . Depend on image 3 It can be seen that the 5.2ppm signal from the double bond of the isoprene unit disappears, while the 2.7ppm signal from the epoxy group disappears, indicating that the entire double bond can be converted to hydroxyl or furan by adding isopropanol as a co-solvent ring.

Embodiment 3

[0064]

[0065] A deproteinized natural rubber latex was prepared in the same manner as in Example 1 using a commercially available high-ammonia natural rubber latex (30% by mass solid content).

[0066]

[0067] 14 g of peracetic acid was added to 20 g of the obtained deproteinized natural rubber latex, stirred and mixed, and left still at room temperature for 16 hours. Thereafter, ammonia water was added for neutralization, and washing was repeated several times by centrifugation using distilled water. It was then dried under vacuum to formulate a modified rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com