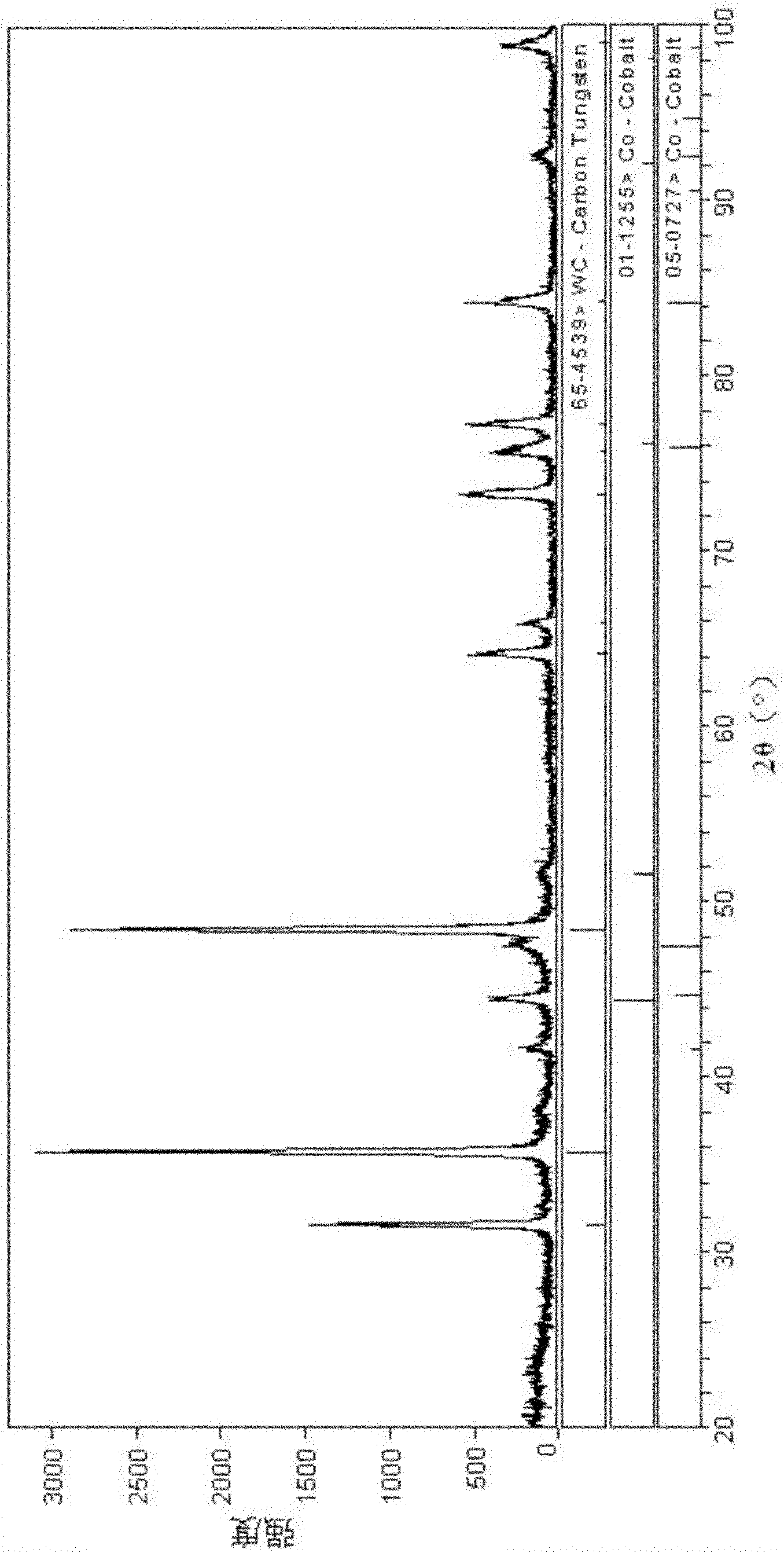

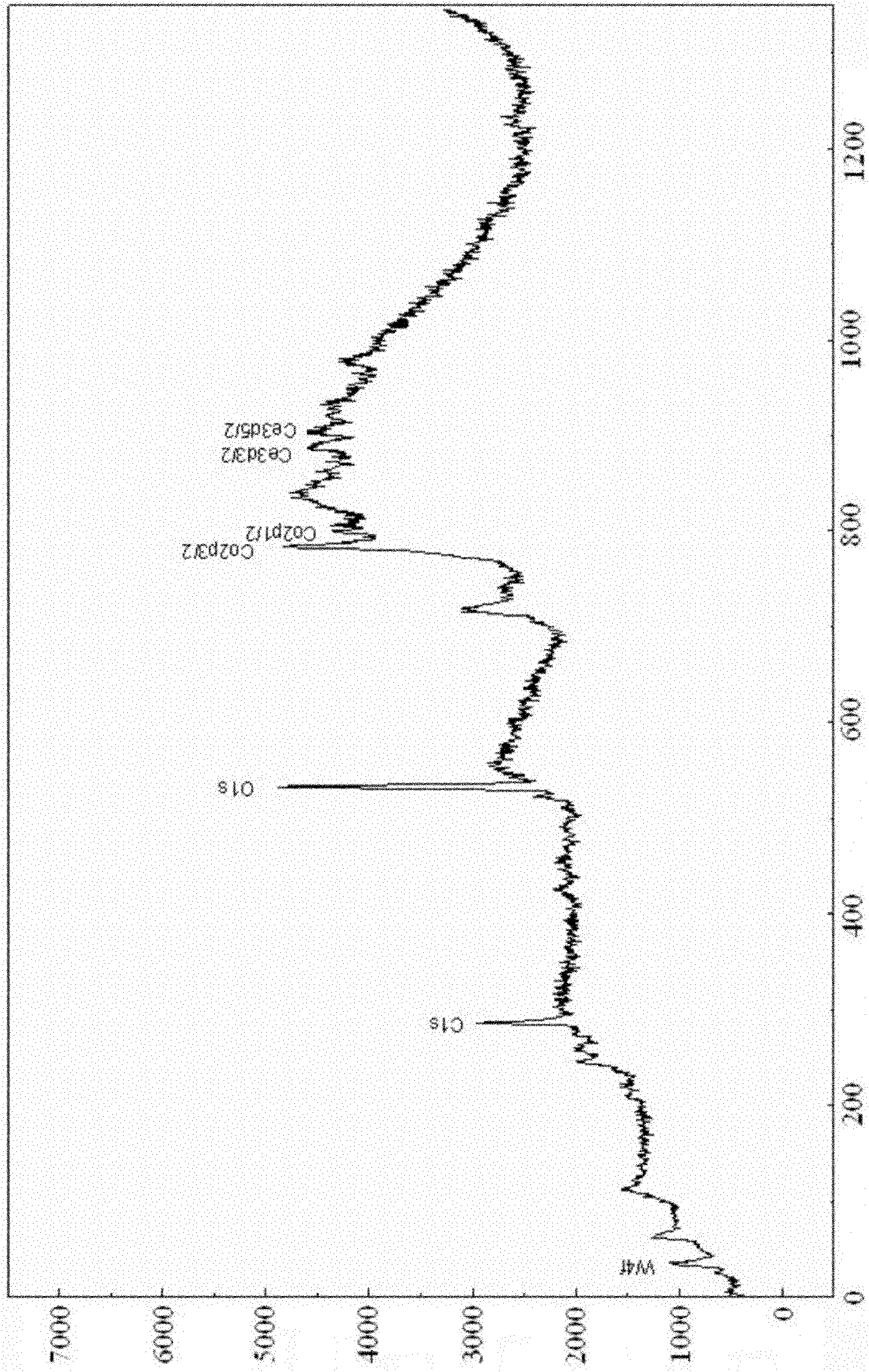

Preparation method of rare-earth modified Co-cladded wolfram carbide hard alloy composite powder

A technology of cobalt-coated tungsten carbide and cemented carbide, applied in the coating and other directions, can solve the problems of easy introduction of impurities, easy segregation, long time consumption of cemented carbide, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

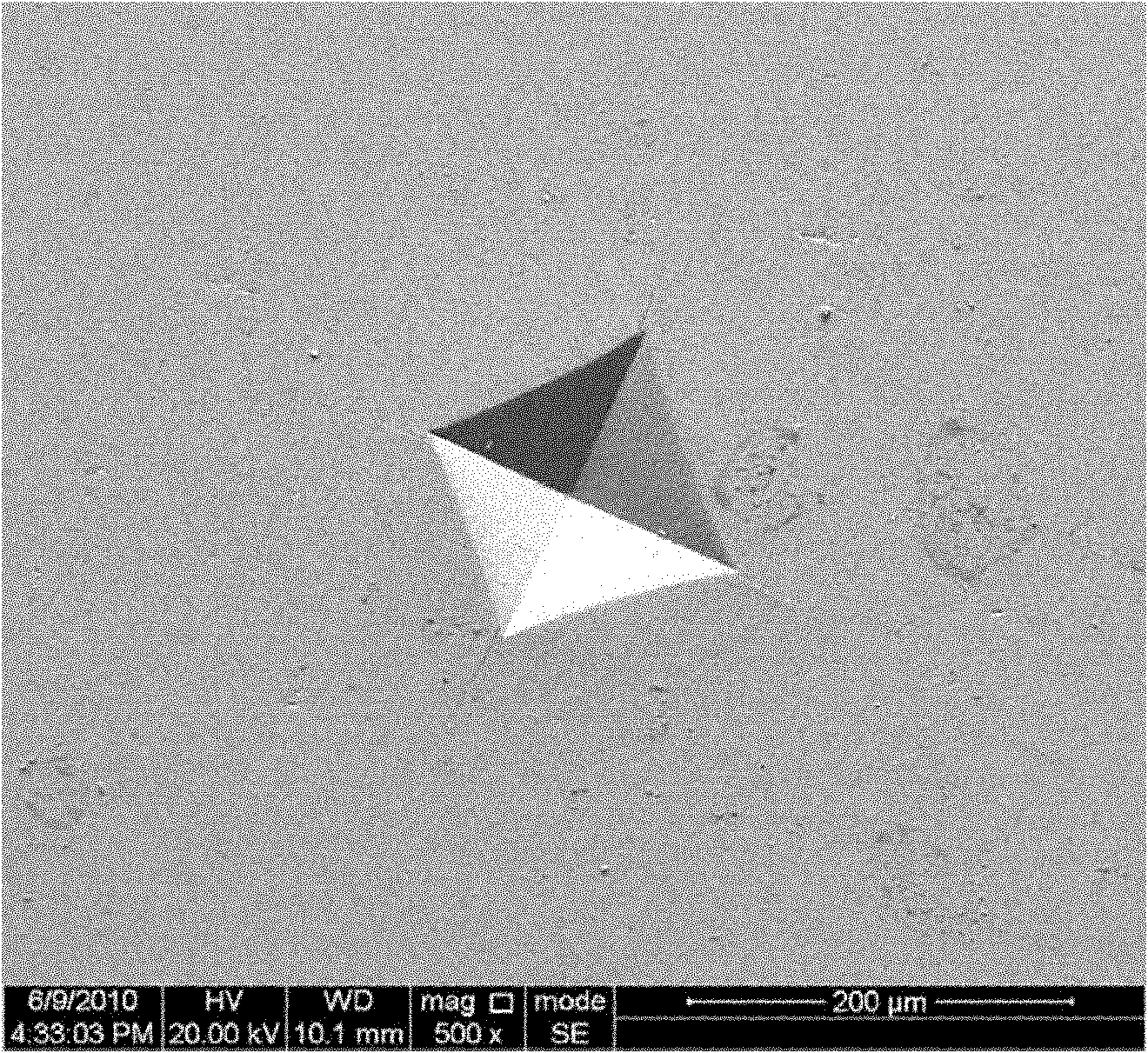

specific Embodiment approach 1

[0012] Specific embodiment one: the preparation method of rare earth modified cobalt-coated tungsten carbide cemented carbide composite powder in this embodiment is carried out according to the following steps: one, under room temperature, CoCl 2 ·6H 2 O was dissolved in ethanol to prepare CoCl with a concentration of 40.36g / L 2 solution, and then add micron-sized WC powder into CoCl according to the composition designed for cemented carbide rare earth modified cobalt-coated tungsten carbide composite powder 2 In the solution, 'Ultrasonic stirring, add 80% hydrazine hydrate, the addition of 80% hydrazine hydrate is CoCl 2 2 / 5 of the volume of the solution, continue ultrasonic stirring for 5 minutes, add NaOH saturated aqueous solution, the amount of NaOH saturated aqueous solution is the same as that of hydrazine hydrate, ultrasonically stir for 30 minutes, let stand for 2 hours, pour off the supernatant, and wash the precipitate with distilled water for five first, and then...

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the ultrasonic frequency of the ultrasonic stirring is 28KHz, and the ultrasonic power is 100-200W. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: In this implementation mode, rare earth modified cobalt-coated tungsten carbide cemented carbide composite powder: WC-10Co-0.5Ce 2 o 3 , the specific preparation method is carried out according to the following steps: one, the CoCl 2 ·6H 2 O was dissolved in ethanol to prepare CoCl with a concentration of 40.36g / L 2 solution, then add 100mL CoCl to 8.95g micron WC powder 2 In the solution, stir ultrasonically, add 80% hydrazine hydrate (model is: 80%, produced by Jinan Luli Chemical Co., Ltd.), the addition of 80% hydrazine hydrate is CoCl 2 2 / 5 of the volume of the solution, continue ultrasonic stirring for 5 minutes, add NaOH saturated aqueous solution, the amount of NaOH saturated aqueous solution is the same as that of hydrazine hydrate, ultrasonically stir for 30 minutes, let stand for 2 hours, pour off the supernatant, and wash the precipitate with distilled water for five times, and then dried in a water bath at 70°C for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com