Organic and inorganic compound fertilizer containing organic mineral and inorganic mineral

A technology of inorganic minerals and compound fertilizers, applied in the field of organic-inorganic compound fertilizers, SV organic-inorganic compound fertilizers, can solve the problems of poor effect, humic acid not activated, etc., to improve soil composition, pollution-free performance and improved Effect of enhanced soil function and enhanced agricultural ecological protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Potato organic and inorganic special fertilizer:

[0022] 1. Formula

[0023] Diatomaceous earth: 18

[0024] Humic acid (dry basis, organic matter≧65%, moisture 20%~25%): 18

[0025] Sheep manure (dry basis, organic matter≧70%, moisture 40%~45%): 23

[0026] Urea (N≧46%): 12.5

[0027] Monoammonium phosphate (N≧11%; P 2 o 5 ≧44%): 12.5

[0028] Potassium sulfate (K 2 O≧50%): 6

[0029] Plaster: 9

[0030] Microbial complex agent: 0.5

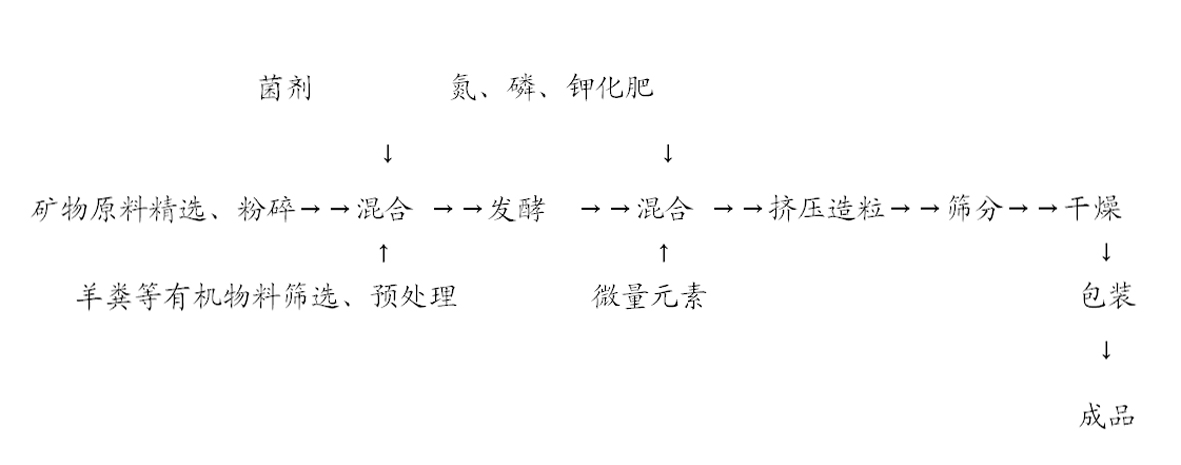

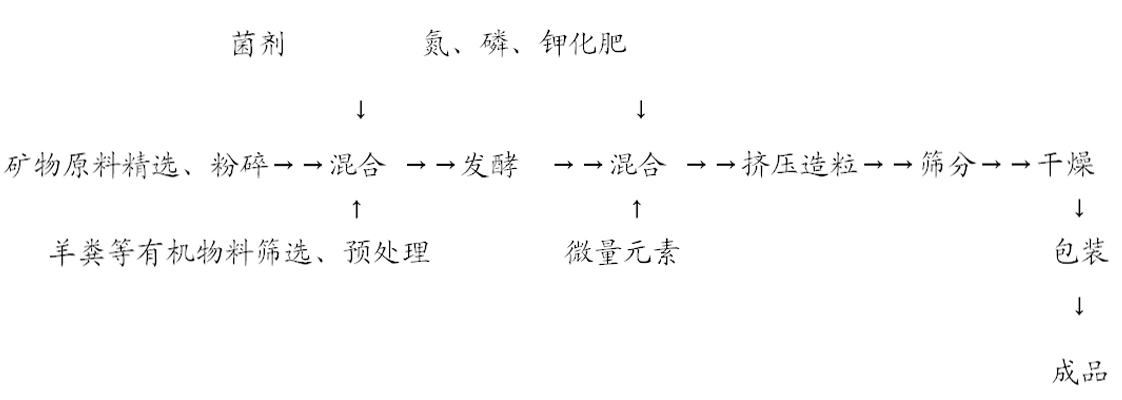

[0032] 2. Production process

[0033] Select and process ores: Mining several porous minerals: diatomite, zeolite, weathered coal humic acid, these raw materials must be selected, dried, impurity removed, crushed and sieved to make them into uniform fineness Powder as required.

[0034] Organic sheep manure, cow manure, chicken manure or organic waste from the food industry, etc. These raw materials must also be selected, dried, impurity removed, crushed and sieved to become a un...

Embodiment 2

[0039] Embodiment 2: buckwheat organic and inorganic special fertilizer:

[0040] 1. Formula

[0041] Diatomaceous earth: 18

[0042] Humic acid (dry basis, organic matter≧65%, moisture 20%~25%): 18

[0043] Sheep manure (dry basis, organic matter≧70%, moisture 40%~45%): 24

[0044] Urea (N≧46%): 14

[0045] Monoammonium phosphate (N≧11%; P 2 o 5 ≧44%): 13.5

[0046] Potassium Chloride (K 2 O≧60%): 2

[0047] Plaster: 10

[0048] Microbial complex agent: 0.5

[0049] 2. The production process is the same as in Example 1.

Embodiment 3

[0050] Embodiment 3: organic and inorganic special fertilizer for grapes:

[0051] 1. Formula

[0052] Diatomaceous earth: 17

[0053]Humic acid (dry basis, organic matter≧65%, moisture 20%~25%): 17

[0054] Sheep manure (dry basis, organic matter≧70%, moisture 40%~45%): 23

[0055] Urea (N≧46%): 12.5

[0056] Monoammonium phosphate (N≧11%; P 2 o 5 ≧44%): 12.5

[0057] Potassium sulfate (K 2 O≧50%): 6

[0059] Plaster: 9

[0060] Microbial complex agent: 0.5

[0061] Boric acid: 0.5

[0062] 2. The production process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com