Preparation method of high transparent polyvinyl chloride resin

A polyvinyl chloride resin and transparency technology, applied in the field of preparation of high-transparency PVC special resin, can solve the problems of limited improvement of resin thermal stability, high price, and high cost of PVC resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

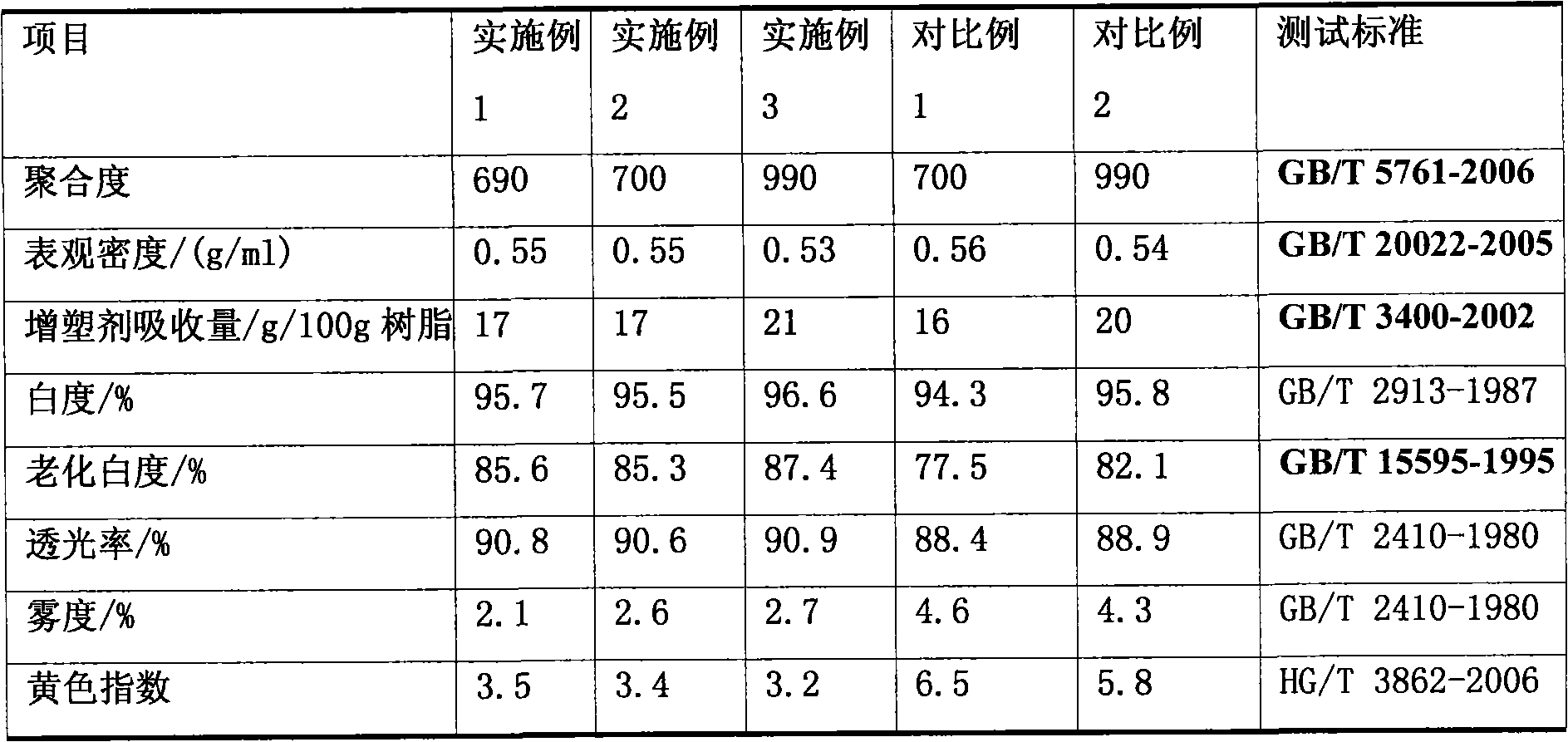

Examples

Embodiment 1

[0037] The polymerization kettle is cleaned and rinsed, and the anti-sticking kettle agent "Italian Yellow" (NOXOL WSW) is coated, and the formula amount (parts by weight) is added:

[0038] Deionized water (DW) 140

[0039] Initiator (TAPP) 0.02

[0040] Initiator (TBPND) 0.035

[0041] Dispersant 1 (E50) 0.03

[0042] Dispersant 2 (PVA80) 0.015

[0043] Dispersant 3 (PVA55) 0.004

[0044] polymeric stabilizer (C 7 -C 10 fatty acid zinc) 0.03

[0045] Chain transfer agent (mercaptoethanol) 0.03

[0046] After vacuuming to a certain degree of vacuum (-0.90MPa), add:

[0047] Vinyl Chloride Monomer (VCM) 100

[0048] Stir coldly for 5 minutes, then warm up to the reaction temperature, and start timing the polymerization. Polymerization process parameter control: polymerization temperature is 61.5±0.5°C; feeding coefficient is 75%; stirring speed is 180r / min; polymerization pressure drop is 0.3MPa. After the pressure drop of the polymerization kettle drops to the proces...

Embodiment 2

[0052] The polymerization kettle is cleaned and rinsed, and the anti-sticking kettle agent "Italian Yellow" (NOXOL WSW) is coated, and the formula amount (parts by weight) is added:

[0053] Deionized water (DW) 140

[0054] Initiator (TAPP) 0.02

[0055] Initiator (TBPND) 0.035

[0056] Dispersant 1 (E50) 0.03

[0057] Dispersant 2 (PVA80) 0.015

[0058] Dispersant 3 (PVA55) 0.004

[0059] polymeric stabilizer (C 7 -C 10 fatty acid zinc) 0.03

[0060] Chain transfer agent (mercaptoethanol) 0.01

[0061] After vacuuming to a certain degree of vacuum (-0.90MPa), add:

[0062] Vinyl Chloride Monomer (VCM) 100

[0063] Stir coldly for 5 minutes, then warm up to the reaction temperature, and start timing the polymerization. Polymerization process parameter control: polymerization temperature is 61.5±0.5°C; feeding coefficient is 75%; stirring speed is 180r / min; polymerization pressure drop is 0.3MPa. When the reaction was carried out for 1.5h, add:

[0064] Chain trans...

Embodiment 3

[0070] The polymerization kettle is cleaned and rinsed, and the anti-sticking kettle agent "Italian Yellow" (NOXOL WSW) is coated, and the formula amount (parts by weight) is added:

[0071] Deionized water (DW) 140

[0072] Initiator (EHP) 0.03

[0073] Initiator (ACPND) 0.05

[0074] Dispersant 1 (E50) 0.017

[0075] Dispersant 2 (PVA80) 0.034

[0076] Dispersant 3 (PVA55) 0.038

[0077] polymeric stabilizer (C 7 -C 10 fatty acid zinc) 0.03

[0078] After vacuuming to a certain degree of vacuum, add:

[0079] Vinyl Chloride Monomer (VCM) 100

[0080] Stir coldly for 5 minutes, then warm up to the reaction temperature, and start timing the polymerization. Polymerization process parameter control: polymerization temperature is 57±0.5°C; feeding coefficient is 75%; stirring speed is 180r / min; polymerization pressure drop is 0.3MPa. After the pressure of the polymerization kettle drops to the process control point, add:

[0081] Composite heat-resistant terminator (di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com