Anticorrosive paint for copper alloy and manufacturing method thereof

An anti-corrosion coating and copper alloy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor coating adhesion, affecting the service life of coatings, etc., to improve adhesion, solve easy peeling, The effect of good anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

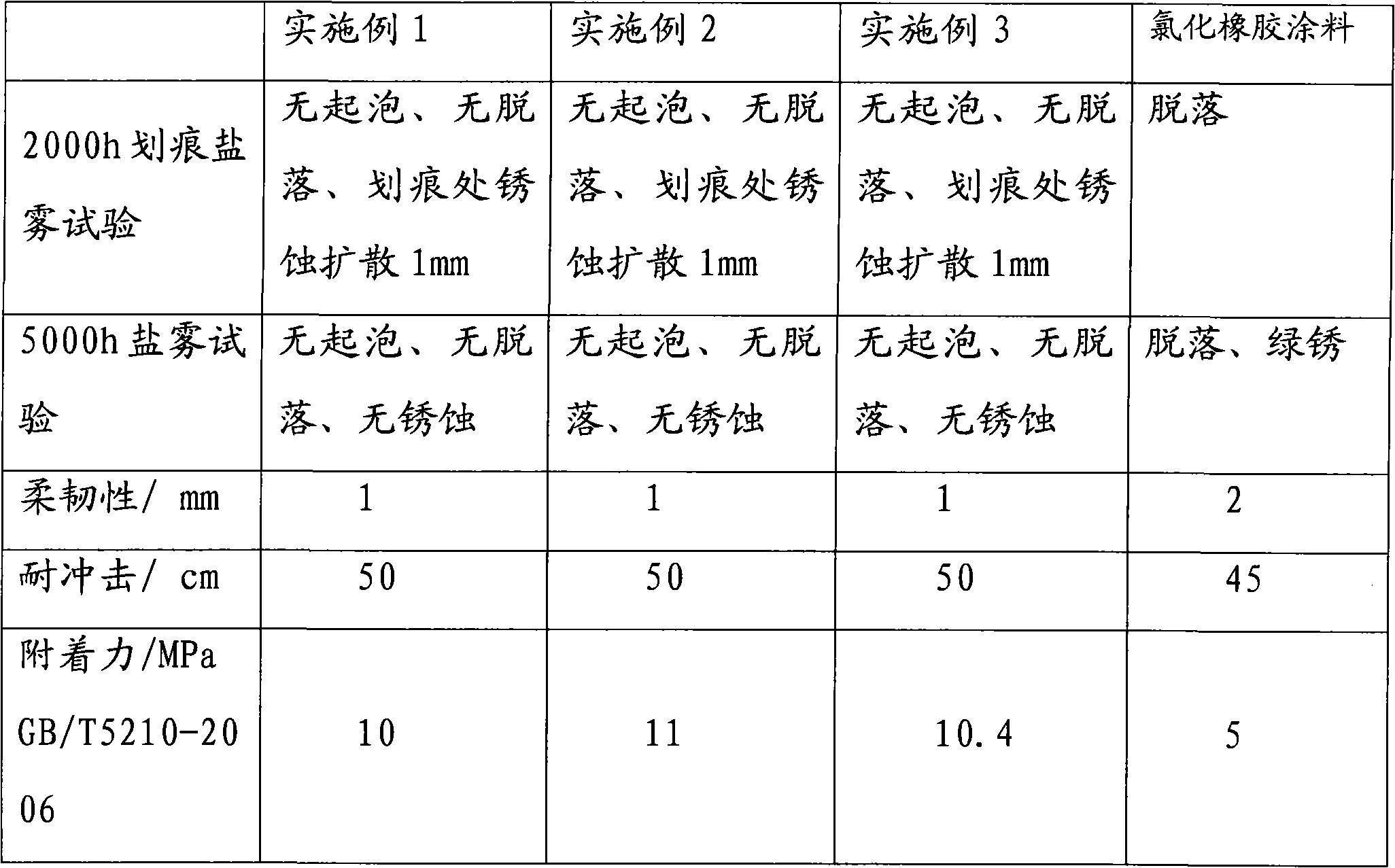

Examples

Embodiment 1

[0076] Formula, percentage by weight is as follows, unit (g)

[0077] main part

[0078] Polyurethane modified epoxy resin 38%

[0080] Talc 4%

[0081] Precipitated barium sulfate 4%

[0082] Dispersant BYK-P104 0.2%

[0083] Defoamer 2700 0.2%

[0084] Leveling agent BYK-344 0.8%

[0085] Anti-sedimentation agent solution 0.8%

[0086] Thinner 15%

[0087] Total 100%

[0088] The polyurethane toughened epoxy resin has an epoxy equivalent of 200-1000 g / mol and a viscosity of 2000-80000 mpa.s.

[0089] Preparation of anti-sedimentation agent solution

[0090] The anti-sedimentation agent is selected from organic bentonite, and the diluent is selected from xylene. The proportioning ratio of organic bentonite to xylene is: organic bentonite: xylene 10%: 90%. The two are mixed together at normal temperature and fully stirred evenly.

[0091] The preparation of the main part

[0092] The preparation of the main part of the coating is carried ou...

Embodiment 2

[0104] Formula, percentage by weight is as follows, unit (g)

[0105] main part

[0106] Polyurethane modified epoxy resin 37%

[0107] Glass flakes 40%

[0108] Iron Oxide Red 8%

[0109] Titanium dioxide 4%

[0110] Dispersant BYK-163 0.2%

[0111] Defoamer 6800 0.2%

[0112] Leveling agent BYK-306 0.8%

[0113]Anti-sedimentation agent solution 0.8%

[0114] Thinner 13%

[0115] Total 100%.

[0116] The polyurethane toughened epoxy resin has an epoxy equivalent of 200-1000 g / mol and a viscosity of 2000-80000 mpa.s.

[0117] Preparation of anti-sedimentation agent solution

[0118] Described anti-sedimentation agent selects fumed silica for use, diluent selects xylene for use, the proportioning of fumed silica and xylene is, fumed silica: xylene 10%: 90%, at normal temperature the two are mixed in Together, stir thoroughly.

[0119] curing agent part

[0120] Modified aromatic amine 80%

[0121] Thinner 20%

[0122] Total 100%

[0123] Preparation of curing ag...

Embodiment 3

[0132] Formula, percentage by weight is as follows, unit (g)

[0133] main part

[0134] Polyurethane modified epoxy resin 40%

[0135] Stainless Steel Flakes 39%

[0136] Titanium dioxide 5%

[0137] Dispersant anti-203 0.2%

[0138] Defoamer BYK-085 0.2%

[0139] Leveling agent BYK-354 0.8%

[0140] Anti-sedimentation agent solution 0.8%

[0141] Thinner 14%

[0142] Total 100%

[0143] curing agent part

[0144] Modified aromatic amine 97%

[0145] Thinner 3%

[0146] Total 100%

[0147] Accelerator part

[0148] Coupling agent KH-570

[0149] Preparation of anti-sedimentation agent solution

[0150] Anti-sedimentation agent selects organic bentonite, diluent selects xylene for use, the proportioning of organic bentonite and xylene is, organic bentonite: xylene is 10%: 90%, mix the two together at normal temperature, fully stir and get final product .

[0151] Preparation of curing agent solution

[0152] The modified aromatic amine curing agent is H-113, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com