Process for smelting ultra clean steel by single-nozzle refining furnace

A single-nozzle refining furnace, ultra-clean technology, applied in the field of iron and steel metallurgy, can solve the problems of prolonging refining time, low desulfurization efficiency, shortening the life of refractory materials, etc., achieving excellent refining efficiency, low content of non-metallic inclusions, and fine particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

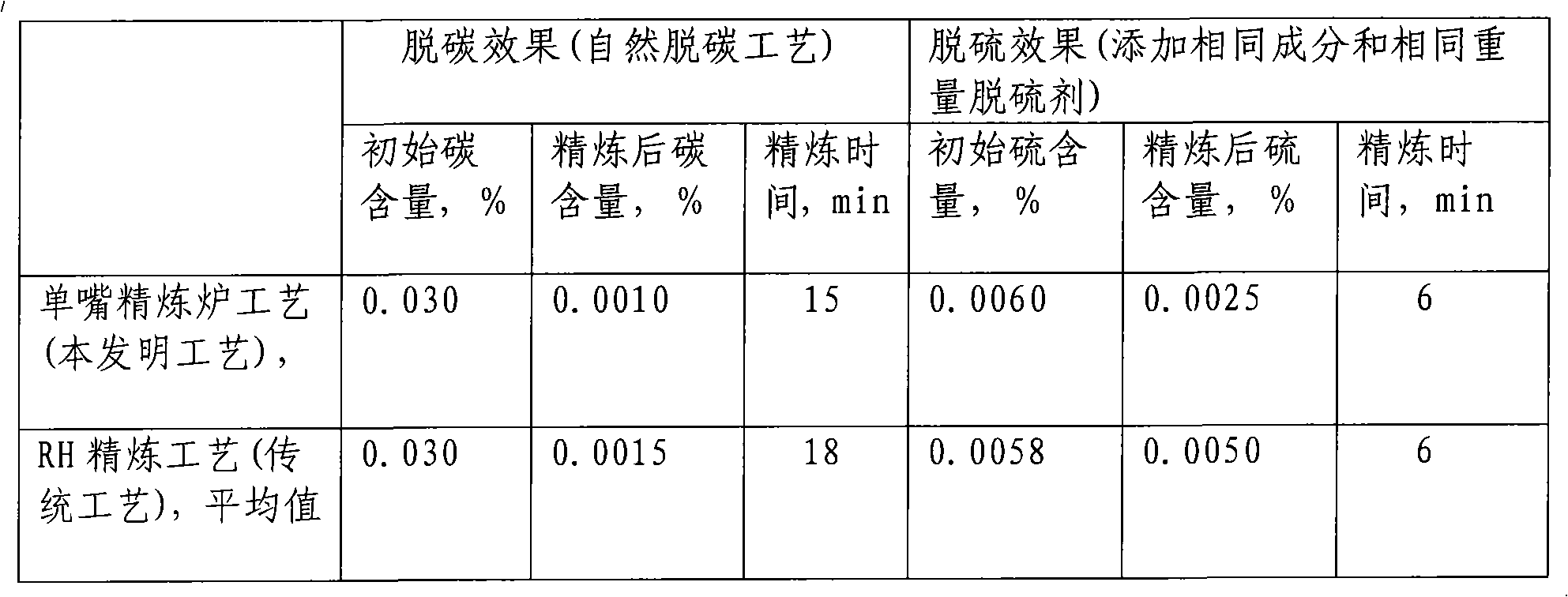

[0061] Converter + single nozzle refining furnace + slab continuous casting process is adopted to smelt ultra-low carbon clean steel by vacuum natural decarburization process.

[0062] The steel is tapped from the converter to the single nozzle refining furnace; molten steel conditions: 100 tons of steel tapping, 0.03% carbon content, 0.08% oxygen content, temperature 1630°C, slag thickness 70mm; free space above the ladle slag surface 500mm, ladle slag Composition: CaO 45%, SiO2 20%, MgO 8%, Al 2 o 3 3%, Fe t O 19%, CaF 2 2%, other residues are not more than 3%.

[0063] When the ladle reaches the single-nozzle refining furnace station, blow argon gas from the bottom of the ladle, control the blowing flow rate to 450NL / min, blow off the slag covered on the surface of the ladle as far as possible, and then insert the suction nozzle into the ladle to a depth of 350mm below the surface, vacuum treatment is carried out as follows:

[0064] The vacuum natural decarburizatio...

Embodiment 2

[0074] Converter + single nozzle refining furnace + slab continuous casting process is adopted to smelt ultra-low carbon clean steel by vacuum forced decarburization process.

[0075] In this embodiment, the process steps are substantially the same as in Embodiment 1, and only the differences are described below, and the similarities are not repeated;

[0076]Conditions of molten steel: carbon content 0.045%, oxygen content 0.04%, temperature 1610°C, slag thickness 50mm; free space above ladle slag surface 500mm, ladle slag composition: CaO 46%, SiO 2 22%, MgO 8%, Al 2 o 3 3%, Fe t O 18%, other residues not more than 3%.

[0077] Insert the suction nozzle into the ladle to a depth of 330mm below the liquid steel surface, and carry out vacuum treatment as follows:

[0078] Using the forced decarburization process, within 3 minutes after the start of vacuum treatment, reduce the pressure in the vacuum chamber to 6KPa, and then start blowing oxygen with the oxygen blowing f...

Embodiment 3

[0082] Converter + single nozzle refining furnace + slab continuous casting process is adopted to smelt ultra-low carbon clean steel with temperature control process.

[0083] In this embodiment, the process steps are substantially the same as in Embodiment 1, and only the differences are described below, and the similarities are not repeated;

[0084] Conditions of molten steel: carbon content 0.03%, oxygen content 0.08%, temperature 1570°C, slag thickness 50mm; free space above ladle slag surface 500mm, ladle slag composition: CaO 46%, SiO 2 22%, MgO 8%, Al 2 o 3 3%, Fe t O 18%, other residues not more than 3%.

[0085] Insert the suction nozzle into the ladle to a depth of 300mm below the liquid steel surface, and carry out vacuum treatment as follows:

[0086] Temperature rise Within 3 minutes after the start of the vacuum treatment, reduce the pressure in the vacuum chamber to 6KPa, then add 200Kg of metal aluminum, and start blowing oxygen with the oxygen blowing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com