Preparation method of high-purity plate-like cordycepin crystal

A high-purity technology for cordycepin, applied in the field of medicine and chemical industry, can solve the problems of high production cost, difficulty in large-scale industrial production, and the preparation method of high-purity sheet cordycepin crystals has never been reported, and achieves equipment investment and production and operation costs. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

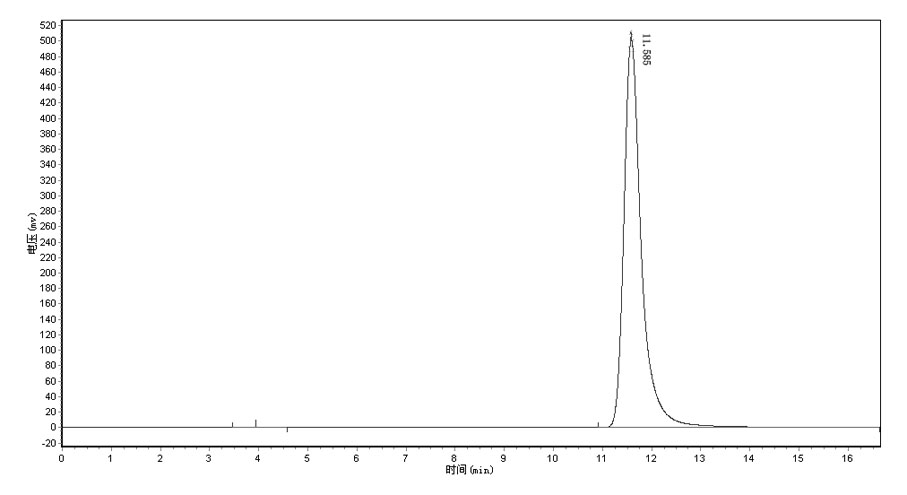

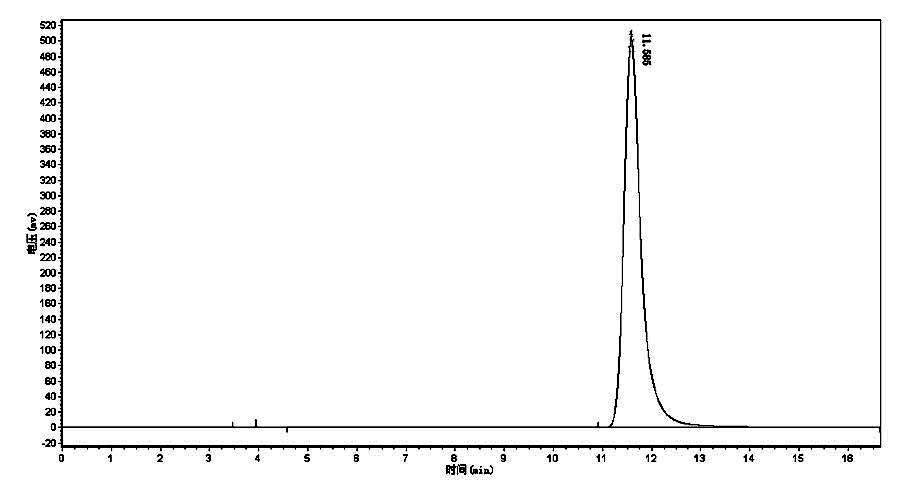

Image

Examples

Embodiment 1

[0033] Take 24.89 kg of pulverized Cordyceps sinensis medium residue particles into a φ30×60cm stainless steel bucket with sealable ends, fill it evenly, without squeezing, and close the bucket tightly with a lid.

[0034] Use a diaphragm pump to pump 50 liters of drinking water from the bottom of the stainless steel barrel. The water extract from the upper end of the stainless steel barrel flows into a stainless steel column (φ10×120cm) containing 9 liters of H-20 macroporous resin from the lower end, and the upper end of the stainless steel column The effluent of the effluent is continuously pumped into the bottom of the stainless steel barrel with a diaphragm pump for water circulation extraction and adsorption at the same time; the opening time of the diaphragm pump, that is, the extraction time is 16h.

[0035] After extraction, 30 liters of 30% (V / V) ethanol aqueous solution was used as the eluent to elute the macroporous resin column with a flow rate of 1 BV / h; the eluent was...

Embodiment 2

[0039] Put 24.32 kg of pulverized Cordyceps militaris medium residue particles into a φ30×60cm stainless steel bucket with sealable ends. The filling should be even, without squeezing, and the bucket should be tightly closed with a lid.

[0040] Use a diaphragm pump to pump 50 liters of drinking water from the bottom of the stainless steel barrel. The water extract from the upper end of the stainless steel barrel flows into a stainless steel column (φ10×120cm) containing 9 liters of H-20 macroporous resin from the bottom. The upper end of the stainless steel column The effluent of the effluent is continuously pumped into the bottom of the stainless steel barrel with a high-pressure diaphragm pump for water circulation extraction. The opening time of the diaphragm pump, that is, the extraction time is 16h.

[0041] Use 30 liters of 20% (V / V) ethanol aqueous solution as the eluent, and use a diaphragm pump to pump the eluent into a stainless steel column equipped with macroporous resi...

Embodiment 3

[0045] Put 250 grams of the crushed Cordyceps militaris culture medium particles into a φ5.0×40cm PVC tube with sealable ends. The filling should be even, without squeezing, and the PVC tube should be tightly covered with a lid.

[0046] Use a peristaltic pump to pump 2500ml of drinking water from the bottom of the PVC pipe. The water extract from the upper end of the PVC pipe flows from the lower end into a glass column (φ2.5×50cm) filled with 100ml H-20 macroporous resin. The upper end of the glass column The effluent of the peristaltic pump is continuously pumped into the bottom end of the PVC pipe for water circulation extraction; the opening time of the peristaltic pump is 16 hours.

[0047] Use 400ml 30% (V / V) ethanol aqueous solution as the eluent, use a peristaltic pump to pump the eluent into a glass column with macroporous resin for elution, with a flow rate of 1BV / h; collect the eluent by rotary evaporation The instrument was concentrated under vacuum and reduced pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com