Method for preparing fatty acid by illegal cooking oil

A fatty acid and gutter oil technology applied in the field of oleochemicals to achieve high efficiency, increase hydrolysis reaction rate, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

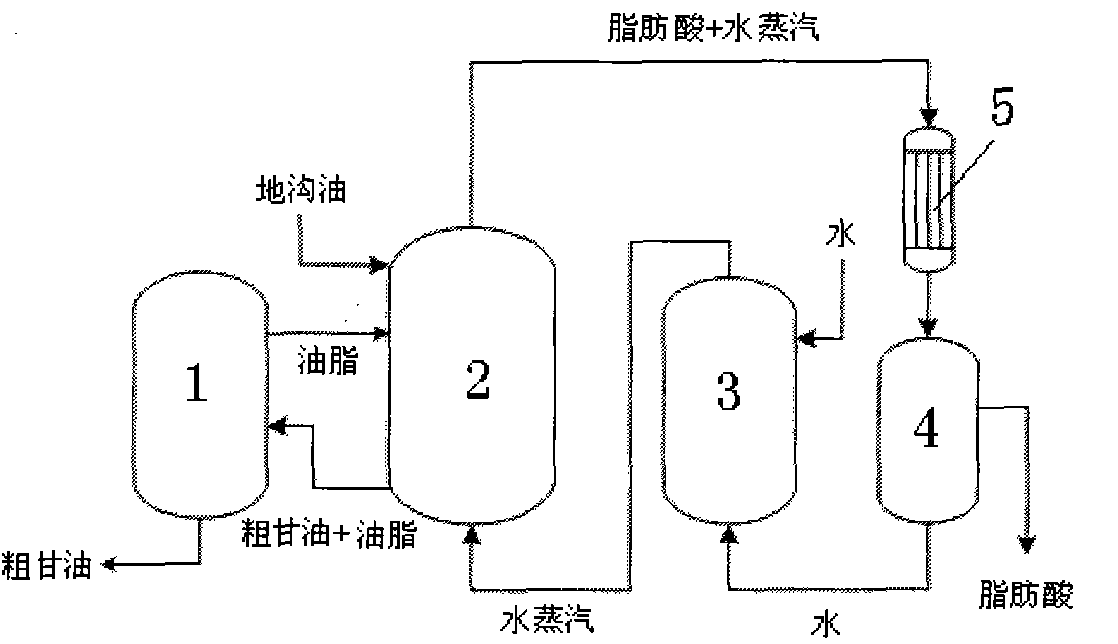

[0018] The method of utilizing waste oil to prepare fatty acid is:

[0019] A. Send water into the steam generator, control the temperature of the steam generator to 110°C and the pressure to 0.10MPa, so that the water evaporates into steam;

[0020] B. Send waste oil with an acid value of 161mgKOH / g into the hydrolysis reactor, and control the temperature of the hydrolysis reactor to 200°C and the pressure to 0.10MPa;

[0021] C, the water vapor of step A is 250m 3 The flow rate of / h is sent to the hydrolysis reaction kettle of step B, so that the waste oil is hydrolyzed with water vapor under high temperature conditions, and fatty acid, crude glycerin and oil are obtained by hydrolysis;

[0022] The fatty acids obtained in steps D and C enter into the condenser along with water vapor, and after conventional condensation, enter the fatty acid separator, control the temperature of the fatty acid separator to be 50° C., and the pressure to be 0.11 MPa to separate the fatty ac...

Embodiment 2

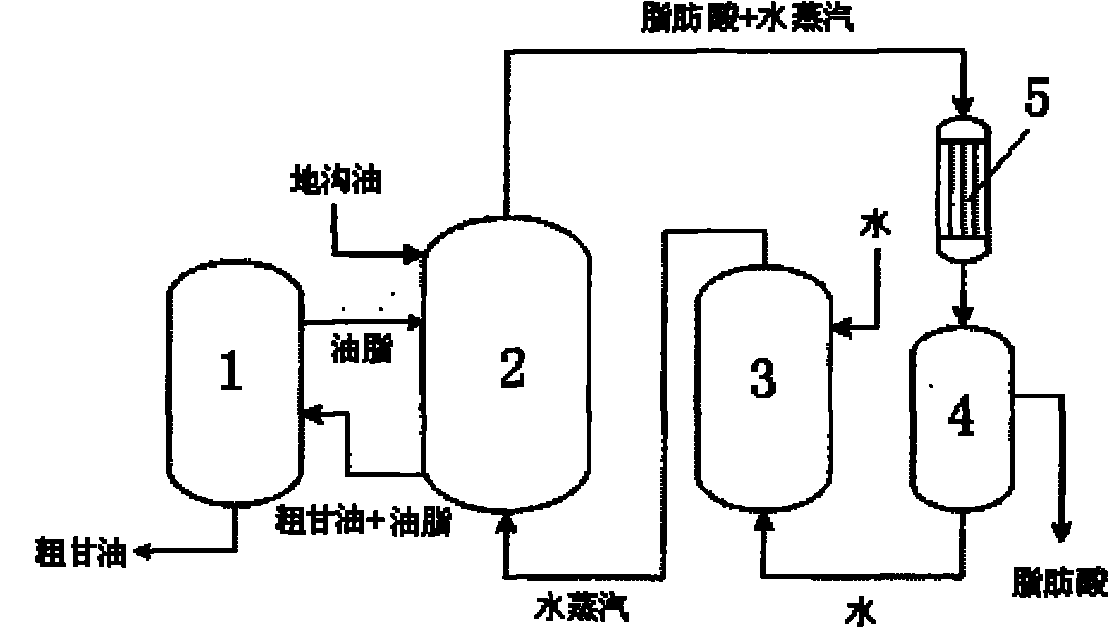

[0026] The method of utilizing waste oil to prepare fatty acid is:

[0027] A. Send water into the steam generator 3, control the temperature of the steam generator 3 to be 105°C and the pressure to be 0.12MPa, so that the water is evaporated into steam;

[0028] B. Send waste oil with an acid value of 163mgKOH / g into the hydrolysis reactor 2, and control the temperature of the hydrolysis reactor 2 to be 250°C and the pressure to be 0.12MPa;

[0029] C, the water vapor of step A is 200m 3 The flow rate of / h is sent into the hydrolysis reaction kettle 2 of step B, so that the waste oil is hydrolyzed with water vapor under high temperature conditions, and fatty acid, crude glycerin and oil are obtained by hydrolysis;

[0030] D, the fatty acid obtained in step C enters the condenser 5 along with water vapor, and after conventional condensation, enters the fatty acid separator 4 again, and the temperature of the fatty acid separator 4 is controlled to be 50°C and the pressure i...

Embodiment 3

[0034] The method of utilizing waste oil to prepare fatty acid is:

[0035] A. Send water into the steam generator 3, control the temperature of the steam generator 3 to be 100°C and the pressure to be 0.15MPa, so that the water is evaporated into steam;

[0036] B. Send waste oil with an acid value of 162mgKOH / g into the hydrolysis reactor 2, and control the temperature of the hydrolysis reactor 2 to be 230°C and the pressure to be 0.09MPa;

[0037] C, the water vapor in step A is 225m 3 The flow rate of / h is sent into the hydrolysis reaction kettle 2 of step B, so that the waste oil is hydrolyzed with water vapor under high temperature conditions, and fatty acid, crude glycerin and oil are obtained by hydrolysis;

[0038] The fatty acid obtained in D and C steps enters the condenser 5 along with water vapor, and after conventional condensation, enters the fatty acid separator 4, and controls the temperature of the fatty acid separator 4 to be 80° C. and a pressure of 0.10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com