Control method for brushless direct current motor for automotive air conditioning fan

A brushed DC motor, automotive air conditioner technology, applied in AC motor control, motor generator control, electronic commutation motor control, etc. Air conditioning system and other problems, to avoid control delay, improve fast dynamic response and steady-state speed regulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

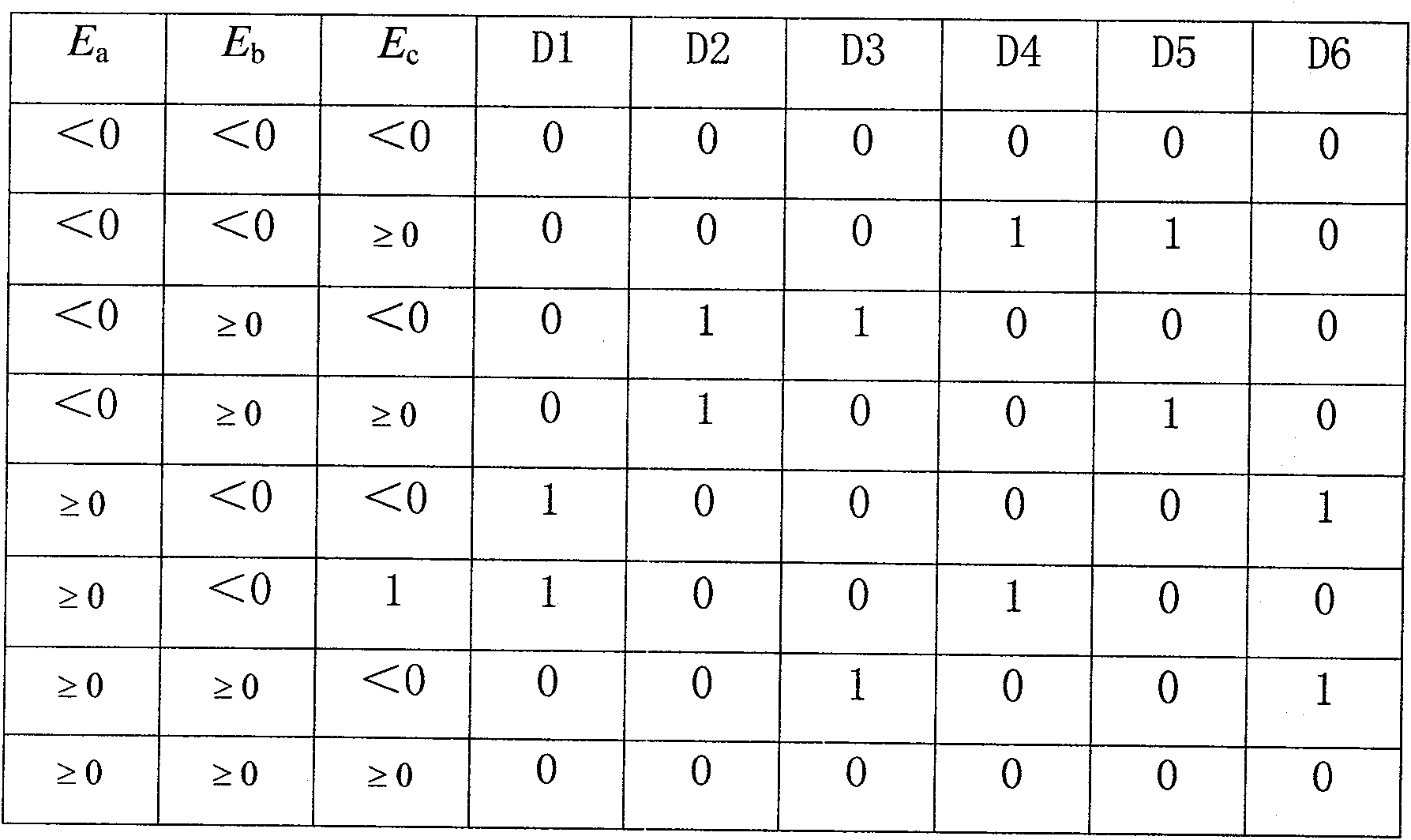

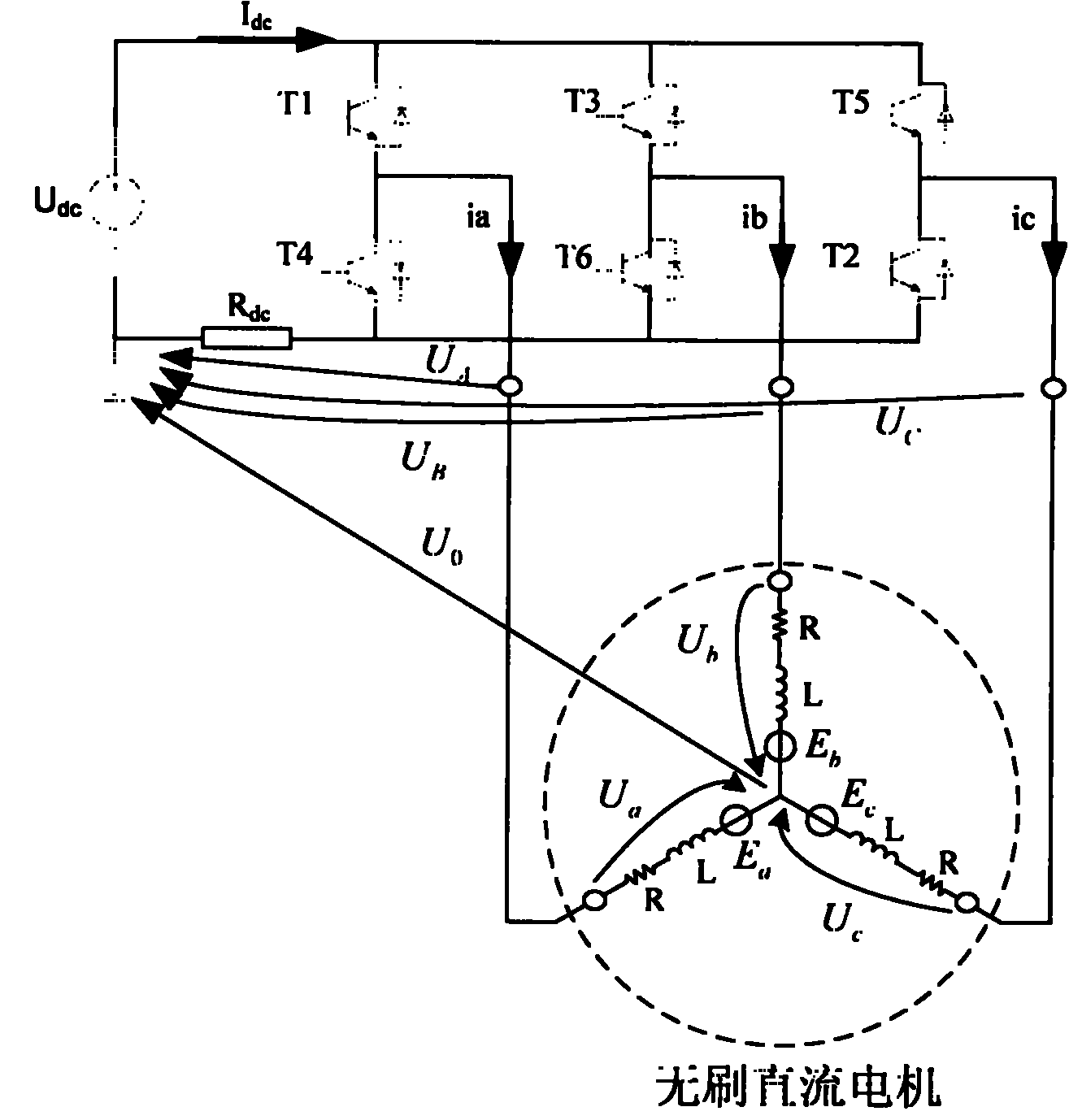

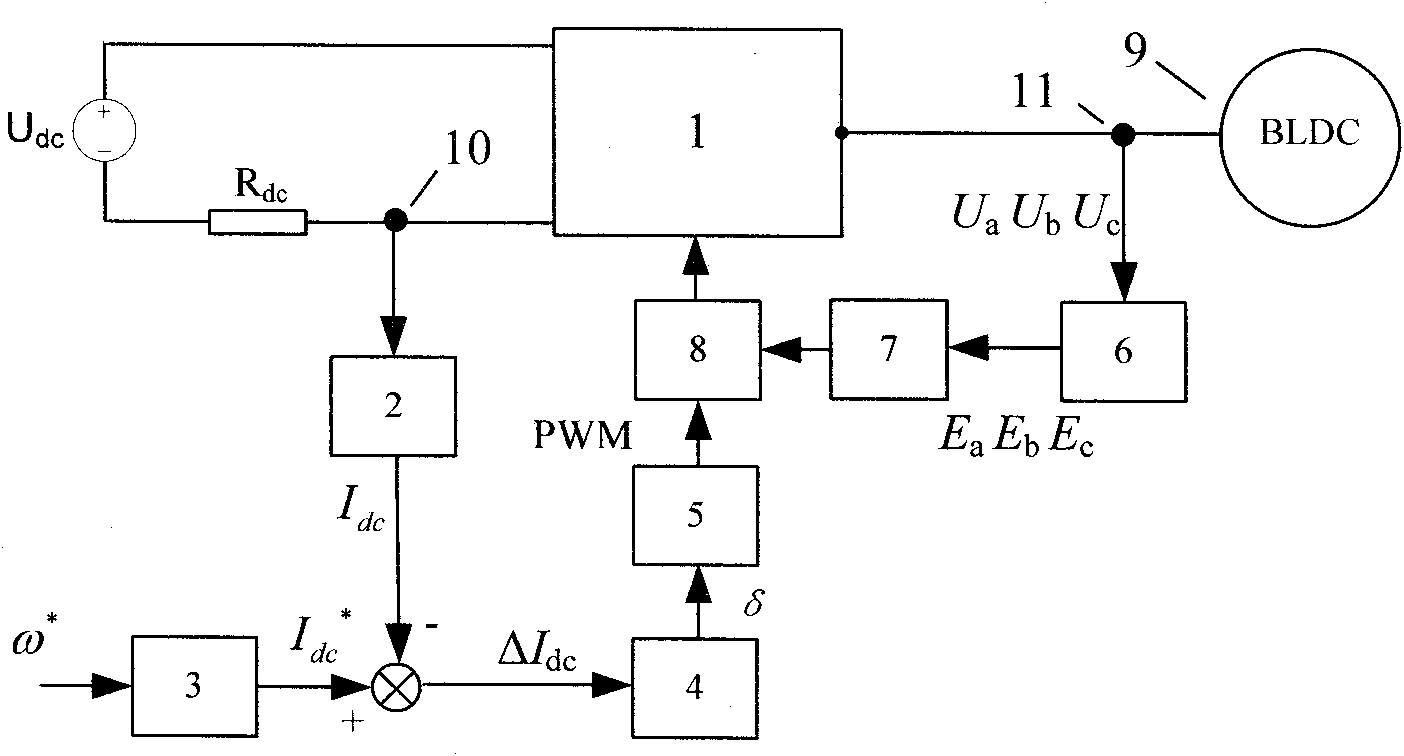

[0025] figure 2 It is a schematic diagram of a brushless DC motor control method for an automobile air-conditioning fan proposed by the present invention. It includes the control object brushless DC motor BLDC 9, the inverter 1 composed of six switching tubes connected to the BLDC stator winding, the Hall sensor 10 for DC bus current detection and the BLDC three-phase terminal voltage U a , U b , U c The detected Hall sensor 11, the low-pass filter 2 used to filter out the high-frequency component of the DC bus current, the function generator 3 used to obtain the reference DC bus current according to the given speed, and the tracking control of the DC bus current Proportional-integral controller 4, a controller 5 used to generate a PWM signal for speed regulation, according to the three-phase terminal voltage U a , U b , U c Extract the three opposite potentials E a ,E b ,E c Module 6, according to the back EMF E a ,E b ,E c The module 7 for determining the commuta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com