Probiotic powder and preparation method

A technology of probiotics and bacteria powder, applied in biochemical equipment and methods, methods based on microorganisms, food preparation, etc., can solve the problems of low utilization value, inability to guarantee bacterial flora, weak functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

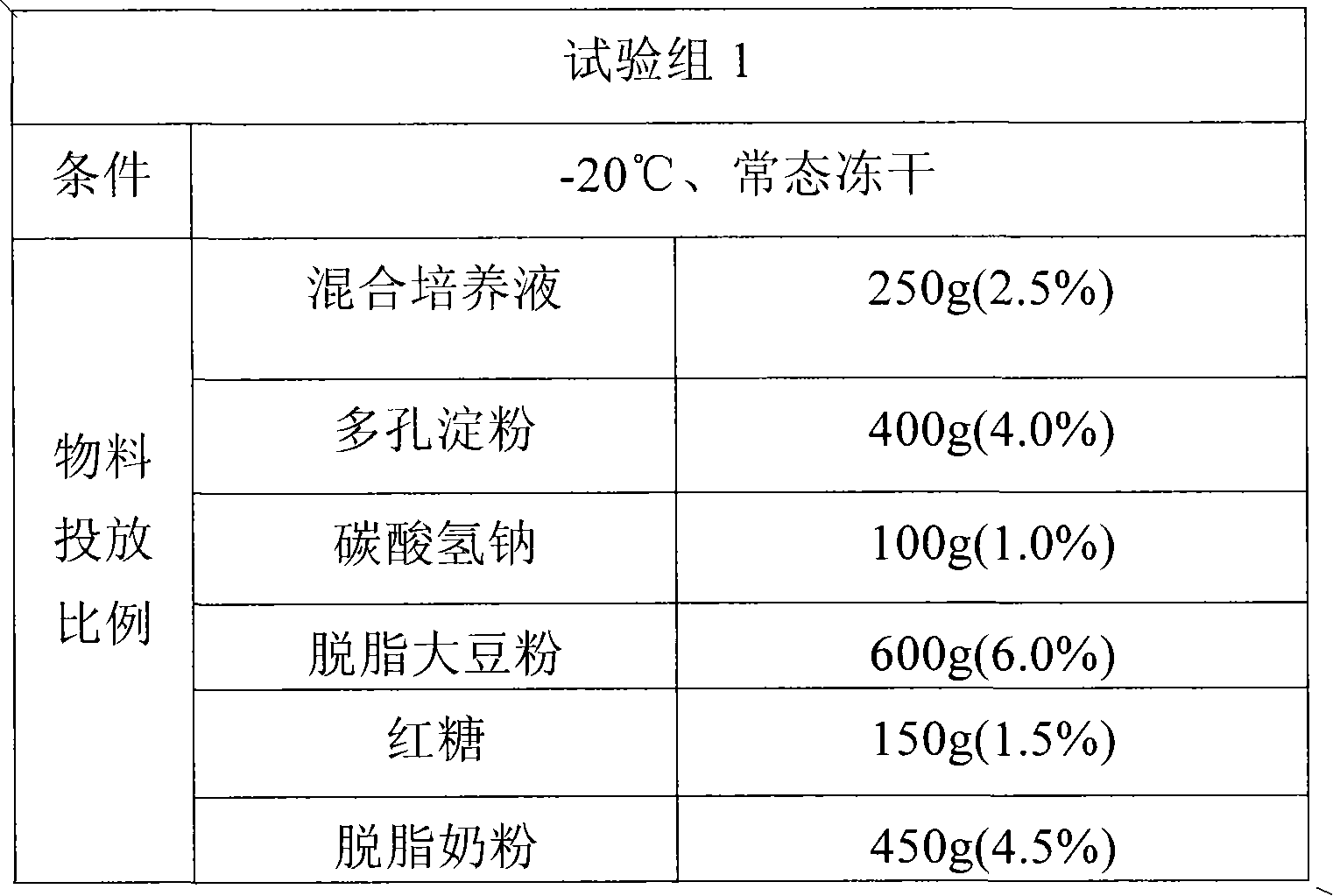

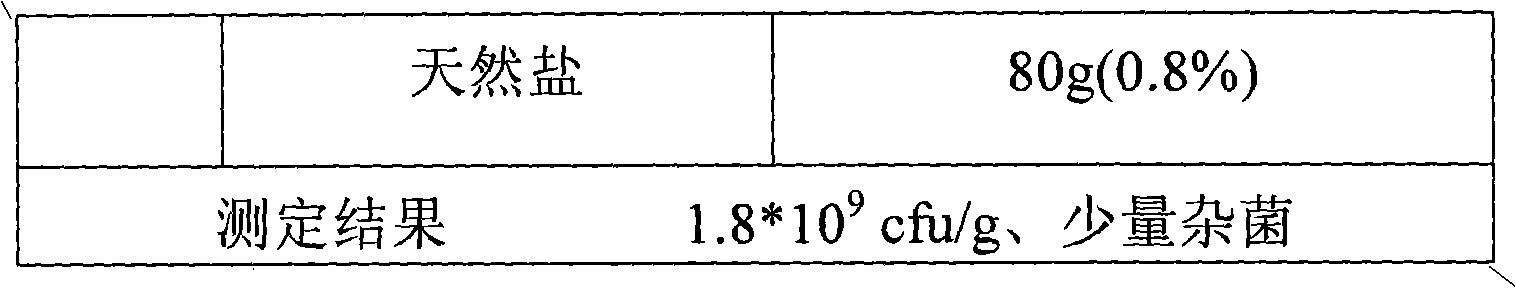

[0006] The preparation method of this mixed probiotic product is to mix 2.5% to 3.0% of the mixed culture solution (weight ratio) of probiotics, 4% to 5% of skimmed milk powder, 0.8% of natural salt, 1% of sodium bicarbonate, and 3% of porous starch. ~5%, defatted soybean powder 5%~7%, brown sugar 1%~2%, add purified water to 100% and stir and mix. The vacuum freeze dryer below performs freeze-drying to produce powdered probiotic bacteria powder with an average particle size of 1 μm to 9 μm.

[0007] The advantage of the present invention is that the mixed probiotic product has a high bacteria rate, complete functions, sufficient nutrition, and is a powder of extremely fine microcells, which can be added to food as a health food and nutritional product. Supplements, and can be used as core functional ingredients in feed additives. In addition, because the powder is protected by porous starch and sugar, it has good acid resistance, low temperature resistance and salt resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com