Preparation method of reverse osmosis composite membrane containing nano zeolite molecular sieves

A reverse osmosis composite membrane and nano-zeolite technology are applied in the field of preparation of a reverse osmosis composite membrane containing nano-zeolite molecular sieves, can solve problems such as no research reports, and achieve high desalination rate and water flux, good mechanical strength, and a preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

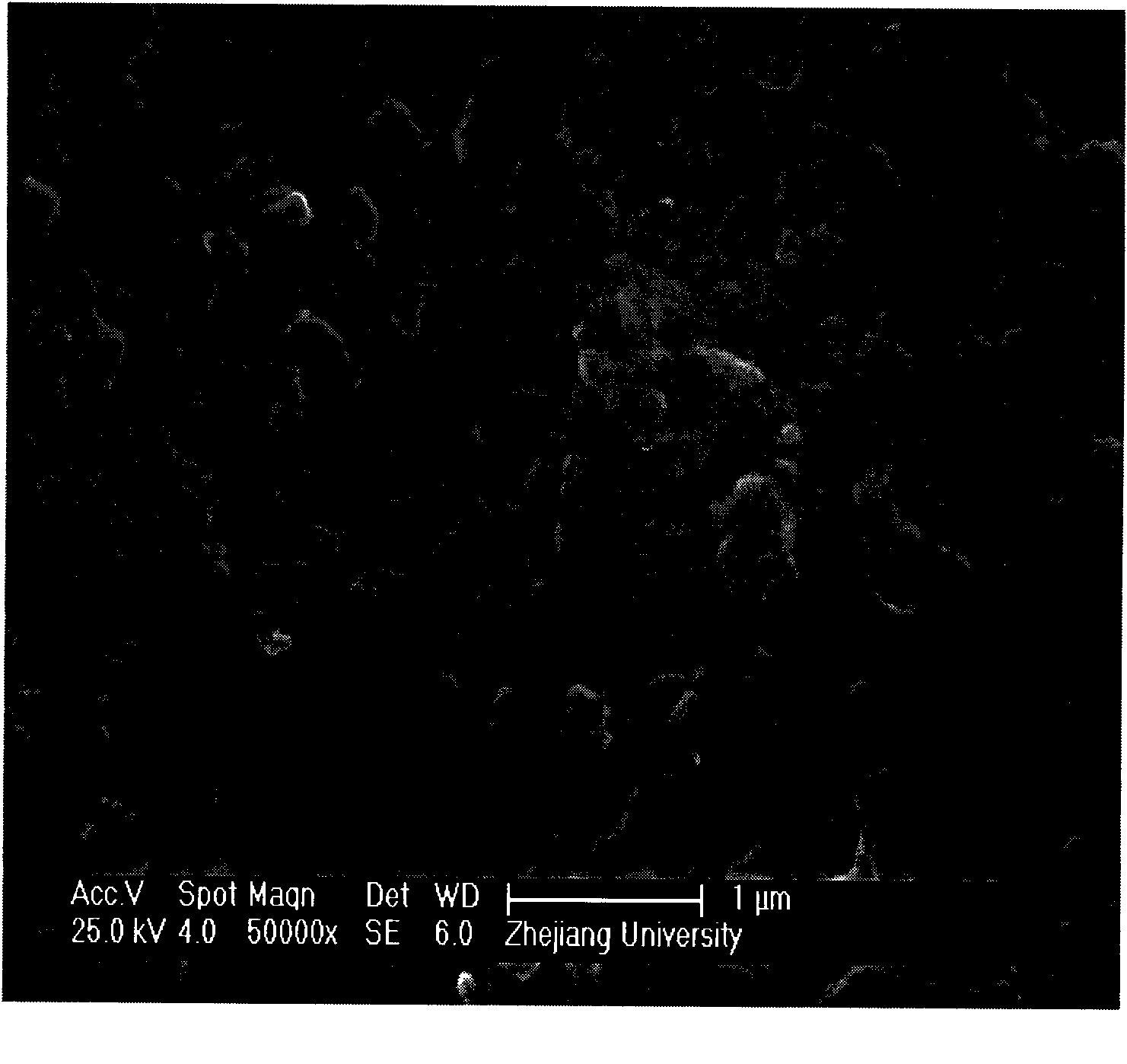

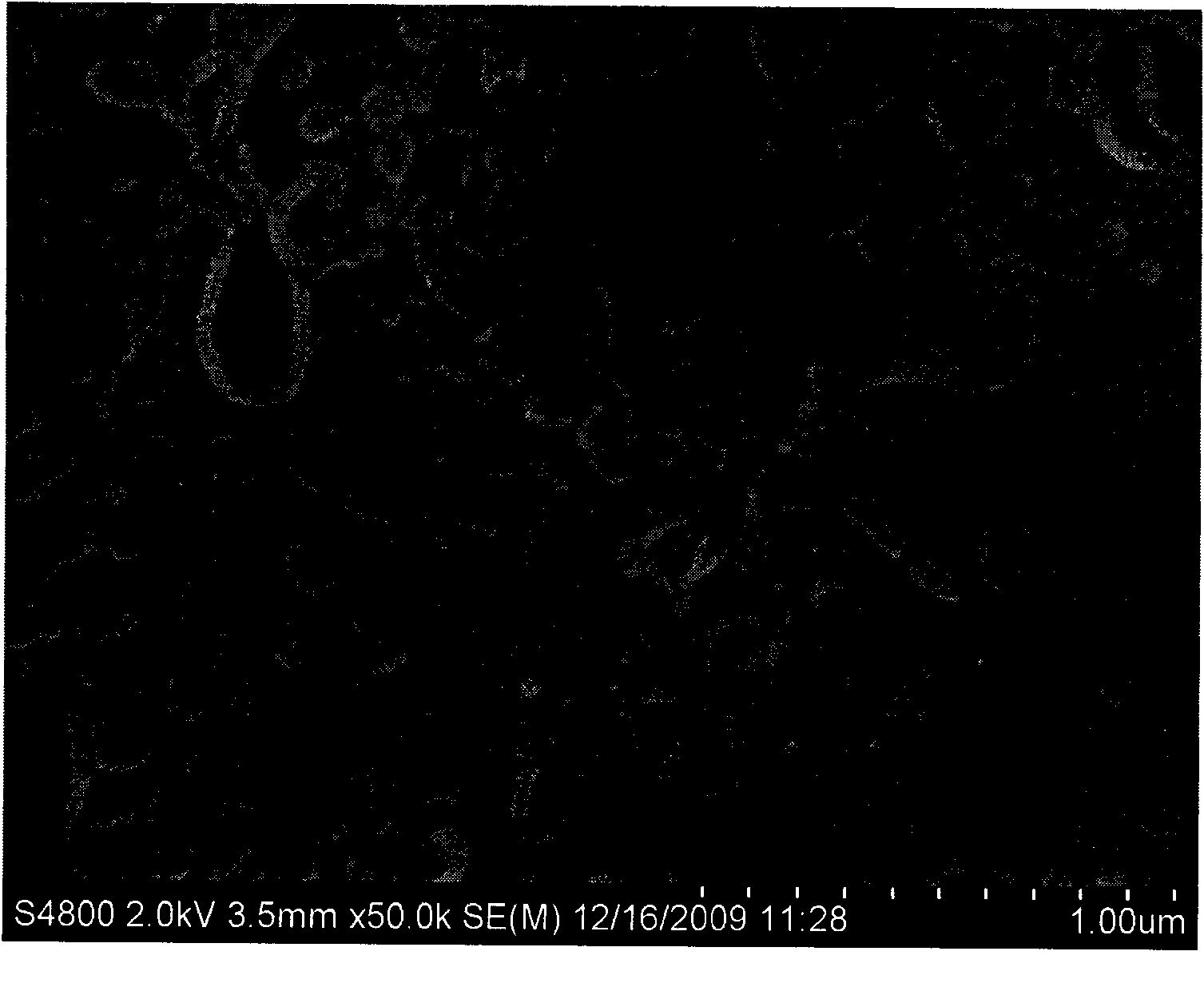

[0031] Disperse the LTA-type nano-zeolite molecular sieve with an average particle size of 60 nanometers in 100 ml of m-phenylenediamine aqueous solution with a concentration of 5% by weight to ensure that the concentration by weight of the LTA-type zeolite molecular sieve is 0.006%, and ultrasonically treat it for 10 minutes at room temperature to obtain a mixture 1g of polysulfone porous ultrafiltration membrane with an average pore diameter of 30 nanometers is directly immersed in the above mixture, the immersion time is 30min, the membrane is taken out, and the moisture on the surface of the membrane is naturally air-dried for 0.5h, and immediately mixed with a concentration of 0.4% by weight. 50ml of benzenetricarboxylic acid chloride n-hexane solution was subjected to interfacial polymerization reaction for 40 seconds to prepare a composite film. The composite film was dried in the air for 2 minutes, then heated in a 60°C oven for 20 minutes, and then rinsed in 40°C water ...

Embodiment 2

[0033] Disperse the LTA-type nano-zeolite molecular sieve with an average particle size of 65 nanometers into 100 ml of m-phenylenediamine aqueous solution with a concentration of 8% by weight to ensure that the concentration by weight of the LTA-type zeolite molecular sieve is 0.012%, and ultrasonically treat it for 20 minutes at room temperature to obtain a mixture 1g of polysulfone porous ultrafiltration membrane with an average pore diameter of 30 nanometers is directly immersed in the above mixture, the immersion time is 40min, the membrane is taken out, and the moisture on the surface of the membrane is naturally air-dried for 0.5h, and immediately mixed with a concentration of 0.6% by weight. 50ml of benzenetricarboxylic acid chloride n-hexane solution was subjected to interfacial polymerization reaction for 50s to prepare a composite membrane. The composite membrane was dried in the air for 2 minutes, then heated in a 60°C oven at a constant temperature for 20 minutes, a...

Embodiment 3

[0035]Disperse the LTA-type nano-zeolite molecular sieve with an average particle size of 70 nanometers in 100 ml of m-phenylenediamine aqueous solution with a concentration of 5% by weight to ensure that the concentration by weight of the LTA-type zeolite molecular sieve is 0.025%, and ultrasonically treat it for 30 minutes at room temperature to obtain a mixture 1g of polysulfone porous ultrafiltration membrane with an average pore diameter of 30 nanometers is directly immersed in the above-mentioned mixture, and the immersion time is 40min, and the membrane is taken out. 50ml of benzenetricarboxylic acid chloride n-hexane solution was subjected to interfacial polymerization reaction for 60 seconds to prepare a composite film. The composite film was dried in the air for 2 minutes, then heated in a 60°C oven at a constant temperature for 20 minutes, and then rinsed in 40°C water for 10 minutes to obtain nano Zeolite molecular sieve reverse osmosis composite membrane, the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com