Method for increasing production of low-carbon olefins

A technology of low-carbon olefins and products, which is applied in the field of increasing production of low-carbon olefins, and can solve the problem of low yield of low-carbon olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

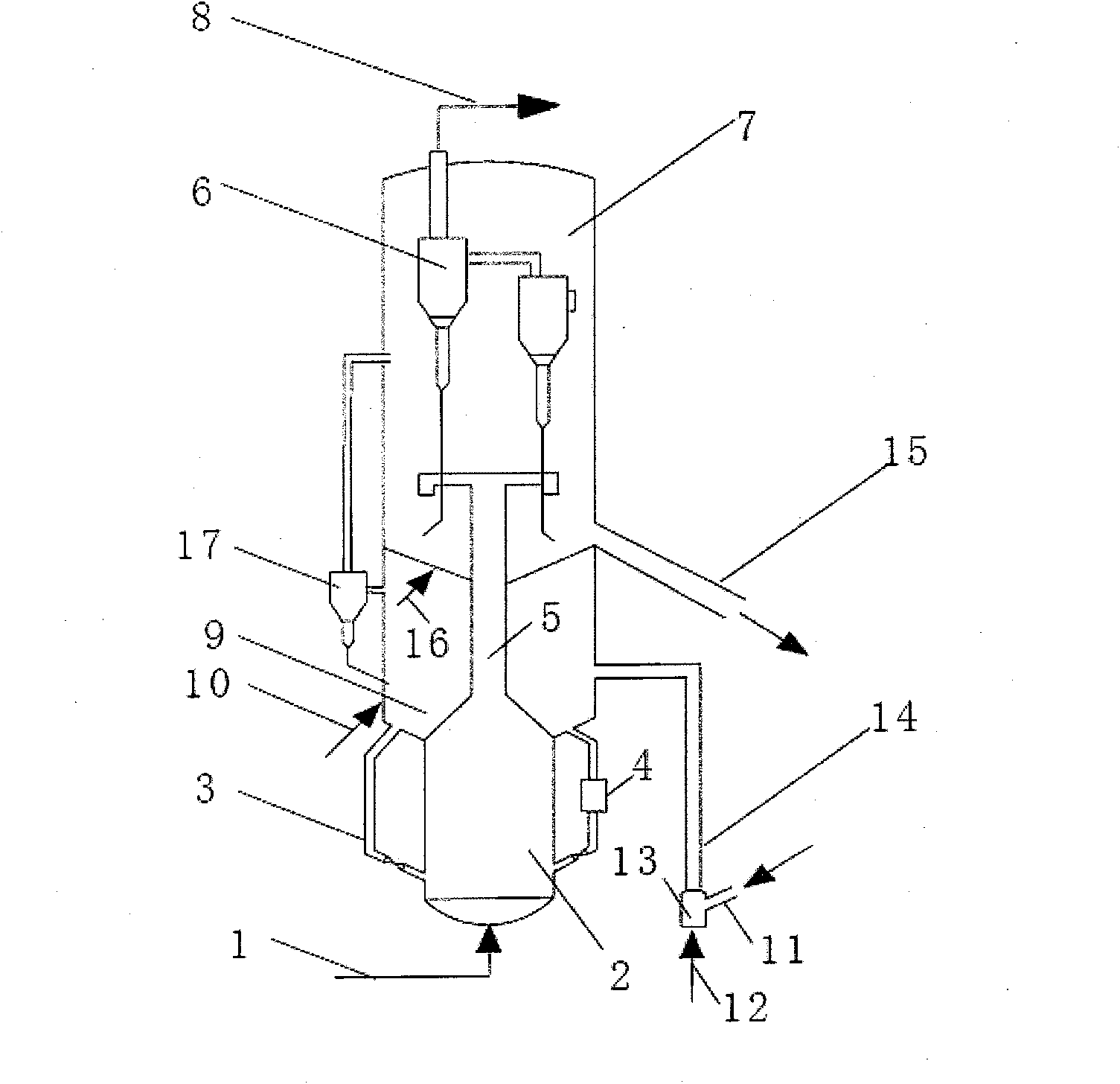

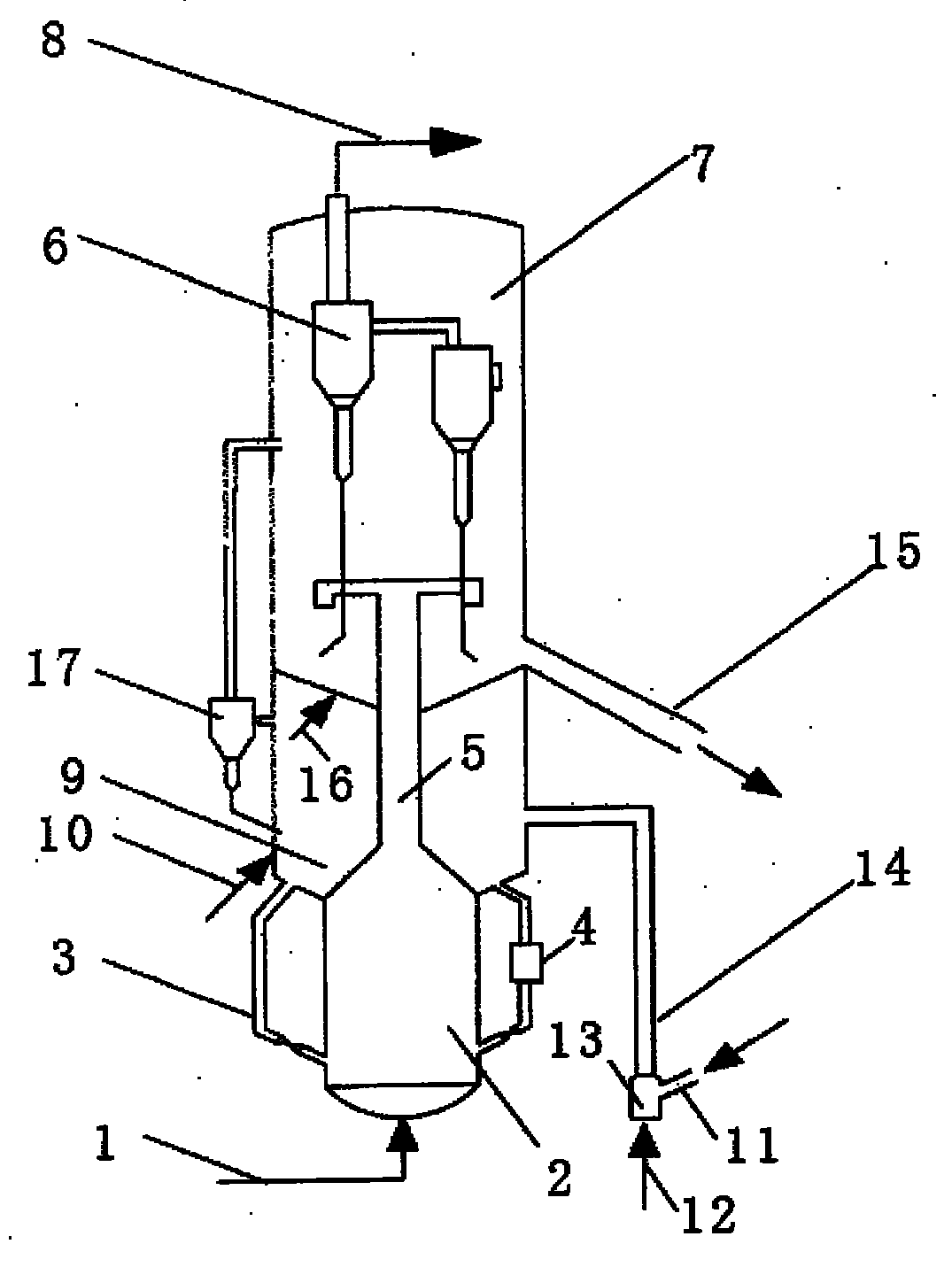

[0018] in such as figure 1 In the shown reaction device, the first reaction zone 2 is a fast fluidized bed, the average temperature is 480° C., the reaction pressure is 0.1 MPa in gauge pressure, and the gas linear velocity is 1.5 m / s; the second reaction zone 14 is a lift tube, the average temperature is 550°C, the reaction pressure is 0.1 MPa by gauge pressure, and the gas linear velocity is 5.0 m / s; the third reaction zone 9 is a dense-phase fluidized bed, the average temperature is 500°C, and the reaction pressure is by gauge pressure Calculated as 0.1MPa, the gas linear velocity is 0.5 m / s. The carbon deposition amount of the pre-carbon deposition catalyst is 0.5% by weight. The feed at the bottom of the first reaction zone 2 is pure methanol, the feed is 2 kg / hour, the catalyst is modified SAPO-34, the feed 12 at the bottom of the second reaction zone 14 is mixed carbon four, and the content of carbon four olefins is 87%. The feed 10 at the bottom of the three reaction...

Embodiment 2

[0020]According to the conditions described in Example 1, the average temperature of the first reaction zone 2 is 500°C, the reaction pressure is 0.2MPa in gauge pressure, and the gas linear velocity is 2.5 m / s; the average temperature of the second reaction zone 14 is 650°C, The reaction pressure is 0.2 MPa in gauge pressure, the linear velocity of gas is 10.0 m / s; the average temperature of the third reaction zone 9 is 630° C., the reaction pressure is 0.2 MPa in gauge pressure, and the linear velocity of gas is 1.0 m / s. The carbon deposition amount of the pre-carbon deposition catalyst is 1.8% by weight. The feed 12 at the bottom of the second reaction zone 14 is mixed carbon tetraolefins, the content of carbon tetraolefins is 58%, and the stability of the catalyst flow control is maintained. The product at the outlet of the reactor is analyzed by online gas chromatography, and the yield of light olefins reaches 85.27% by weight.

Embodiment 3

[0022] According to the conditions described in Example 1, the average temperature of the first reaction zone 2 is 400°C, the reaction pressure is 0.01MPa in gauge pressure, and the gas linear velocity is 0.8 m / s; the average temperature of the second reaction zone 14 is 600°C, The reaction pressure is 0.01MPa in gauge pressure, the linear velocity of gas is 3.0m / s; the average temperature of the third reaction zone 9 is 530°C, the reaction pressure is 0.01MPa in gauge pressure, and the linear velocity of gas is 0.3m / sec. The carbon deposition amount of the pre-carbon deposition catalyst is 0.1% by weight. The stability of catalyst flow control is maintained, and the outlet product of the reactor is analyzed by online gas chromatography, and the yield of low-carbon olefins reaches 85.79% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com