Method for preparing sulfated bagasse xylan

A technology of sulfation and xylan, which is applied in the field of preparation of sulfated bagasse xylan derivatives, can solve the problems of narrow application range and few types, and achieve stable product quality, high raw material utilization rate, and synthetic process easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

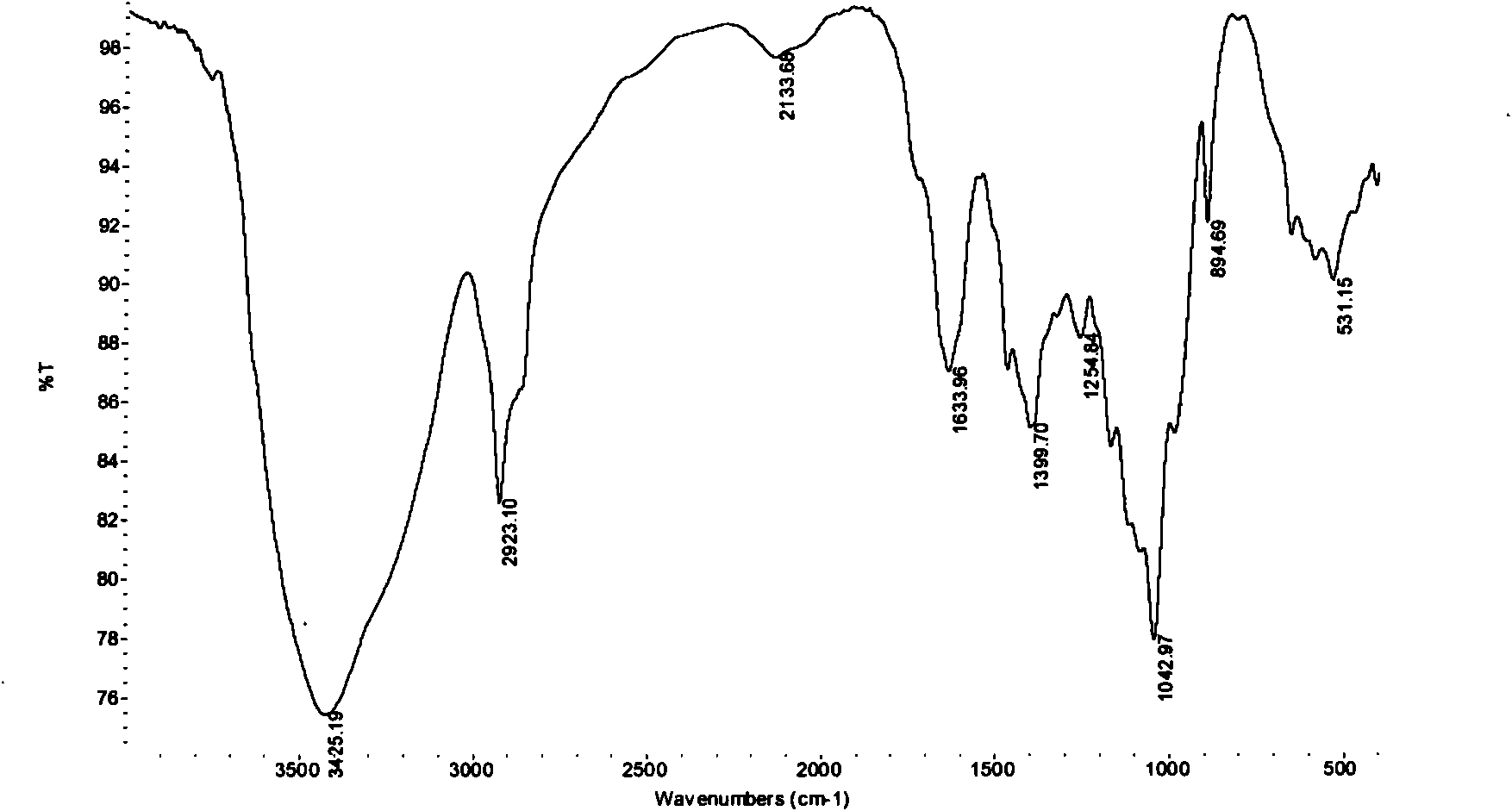

[0019] Dehydrate 40mL of pyridine with 5A molecular sieves, cool in an ice-salt bath, then slowly drop 2mL of chlorosulfonic acid placed in a constant pressure separatory funnel into the pyridine, controlling the flow rate and stirring speed; when a white solid appears in the reaction flask, Add anhydrous formamide to aid dissolution, and continue to stir for 2 hours after the addition of chlorosulfonic acid; move it into a constant temperature water bath adjusted to a temperature of 50°C, and add sulfamic acid as a catalyst accounting for 1% of xylan mass fraction to the reaction system , then add 1g of bagasse xylan, esterify for 3 hours; add excess acetone and let it stand for 2h, pour out the supernatant and add 80% methanol solution by volume, suction filter after sufficient precipitation, collect the precipitate, and repeat washing several times. Obtain the primary product of sulfated bagasse xylan; wash twice with 80% ethanol aqueous solution by volume, then wash and deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com