Preparation method of porous silicon hydrogel interpenetrating network (IPN) membrane

An interpenetrating network and hydrogel technology, which is applied in the field of preparation of silicon hydrogel interpenetrating network film, can solve the problem of limited content of hydrogel components, and is suitable for large-scale production, simple production equipment, and good biological performance. Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

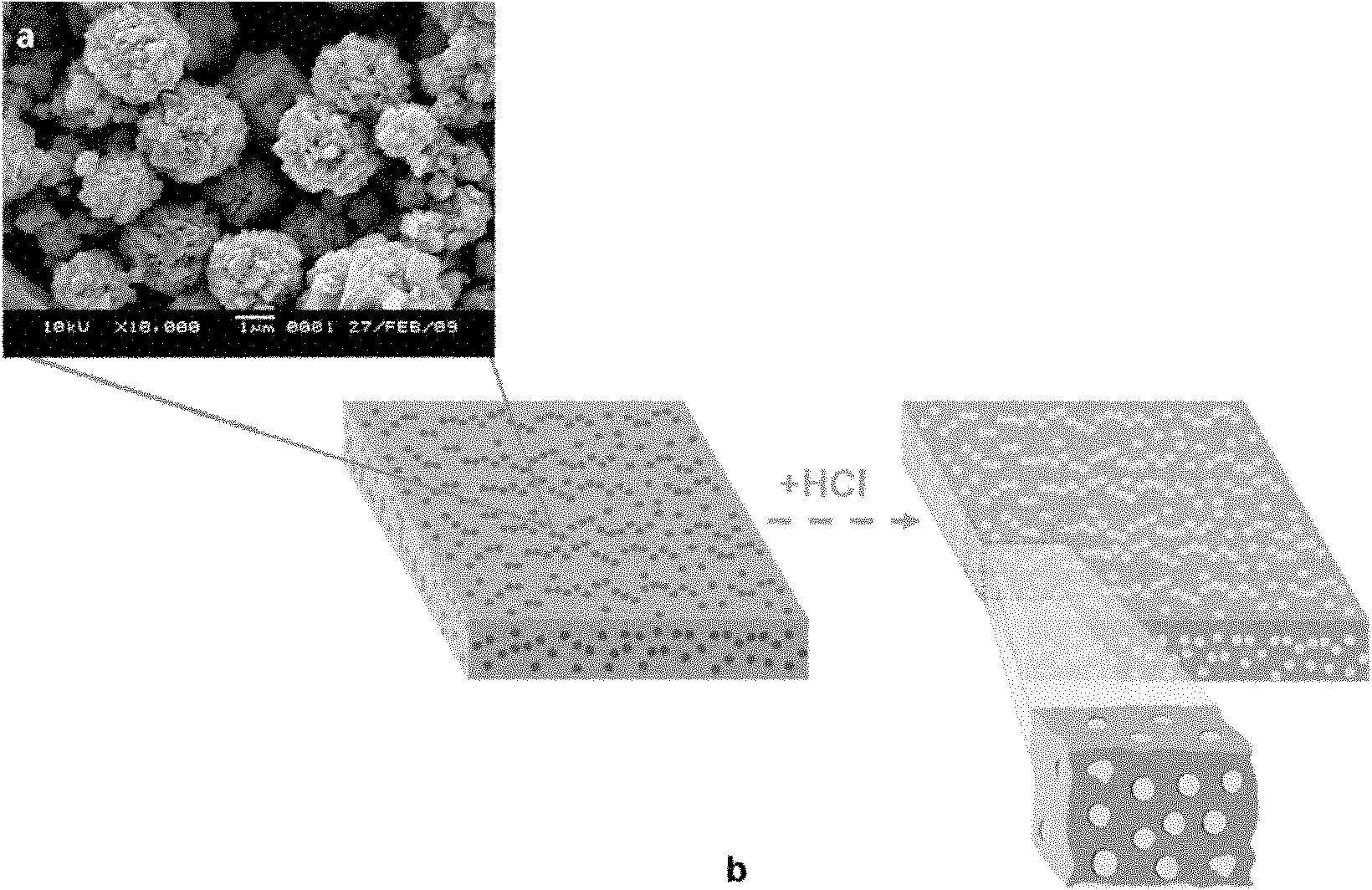

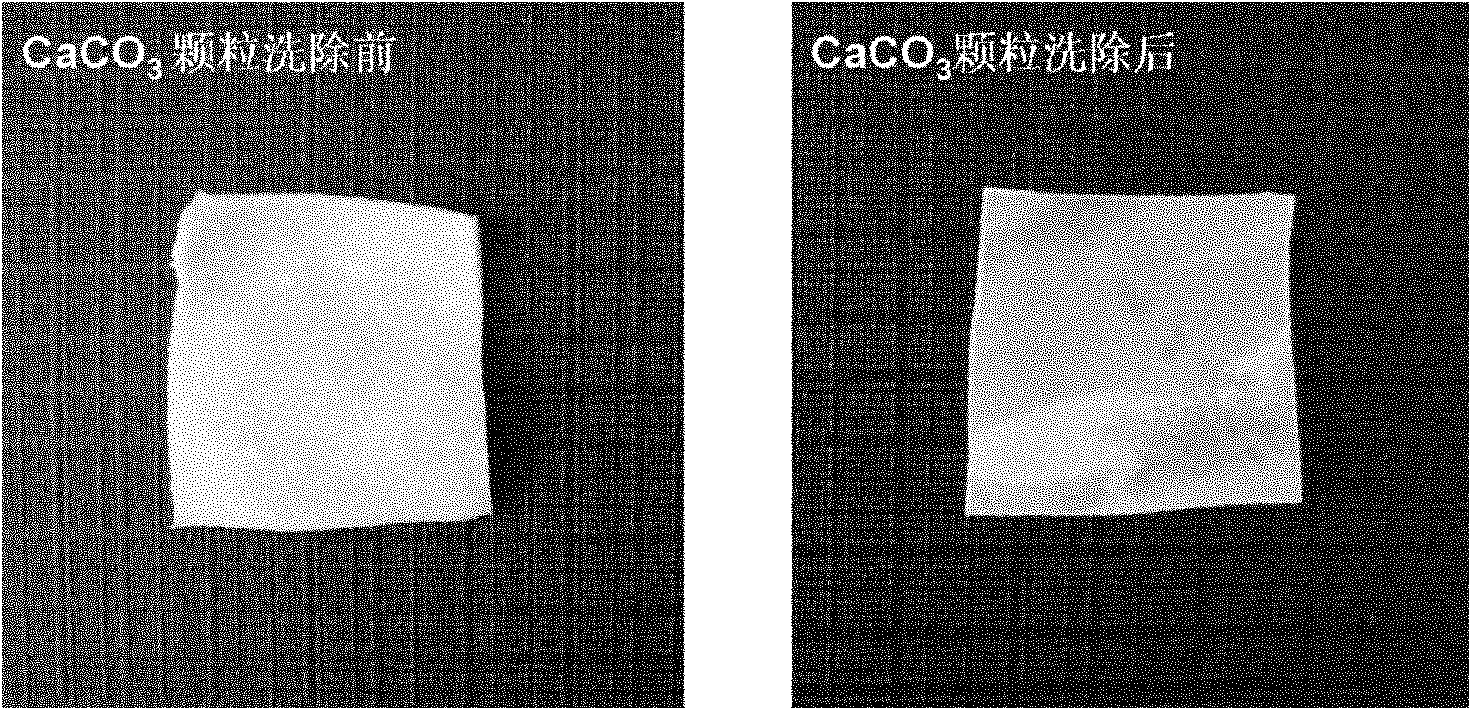

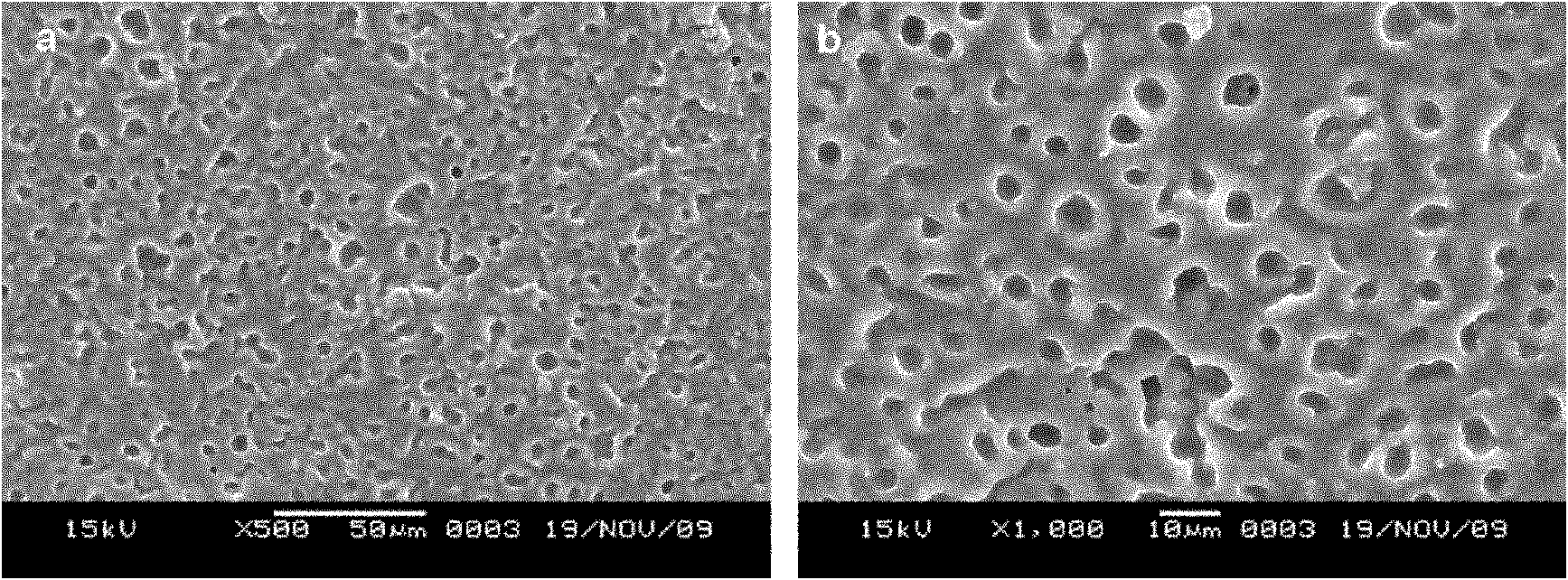

[0039] Weigh 0.3g PEG and dissolve in 300ml 0.1M CaCl 2 and 0.1M Na 2 CO 3 The solution is recorded as solution A and solution B respectively; 1.2g SDS is added to solution B and mixed thoroughly; the prepared solution A is quickly added to solution B, stirred for 1min and left to age at 25°C; the obtained CaCO 3 The microsphere precipitate was repeatedly washed with water 5 times, and dried for later use;

[0040] Prepare the aluminum-zirconium coupling agent with a concentration of 2% aqueous solution, and take the CaCO obtained in the first step 3 Microsphere powder was added to the solution; after ultrasonic vibration treatment, the resulting suspension was poured into a three-necked flask, heated to 40°C and continued to stir at a constant temperature for 1 hour; filtered, dried, and ground to obtain the surface-modified CaCO 3 Template particles;

[0041] Mix 4g PDMS, 0.4g TEOS, 0.12g stannous octoate, dissolve in 2.67g isopropanol, add 0.4g CaCO 3The particles wer...

Embodiment 2

[0045] Weigh 0.2g PEG and dissolve in 100ml 0.05M CaCl 2 and 0.05M Na 2 CO 3 The solutions are recorded as solution A and solution B respectively; 2g of SDS was added to solution B and mixed thoroughly; the prepared solution A was quickly added to solution B, stirred for 1min and left to age at 20°C; the obtained CaCO 3 The microsphere precipitate was repeatedly washed with water 4 times, and dried for later use;

[0046] Prepare the aluminum-zirconium coupling agent with a concentration of 1% aqueous solution, and take the CaCO obtained in the first step 3 Add microsphere powder into the solution; after ultrasonic vibration treatment, pour the resulting suspension into a three-necked flask, raise the temperature to 50°C and continue stirring at constant temperature for 1.5h; filter, dry, and grind to obtain the surface-modified CaCO 3 Template particles;

[0047] Mix 4g PDMS, 0.2g TEOS, 0.04g stannous octoate, dissolve in 1.6g isopropanol, add 0.2g CaCO 3 The particles w...

Embodiment 3

[0051] Weigh 0.4g PEG and dissolve in 400ml 0.3M CaCl 2 and 0.3M Na 2 CO 3 In the solution, record it as solution A and solution B respectively; add 1g SDS to solution B and mix thoroughly; quickly add the prepared solution A to solution B, stir for 2min and stand at 30°C for aging; the obtained CaCO 3 The microsphere precipitate was repeatedly washed with water 6 times, and dried for later use;

[0052] Prepare the aluminum-zirconium coupling agent with a concentration of 4% aqueous solution, and take the CaCO obtained in the first step 3 Add microsphere powder into the solution; after ultrasonic vibration treatment, pour the resulting suspension into a three-necked flask, raise the temperature to 60°C and continue to stir at a constant temperature for 2 hours; filter, dry, and grind to obtain the surface-modified CaCO 3 Template particles;

[0053] Mix 4g PDMS, 0.8g TEOS, 0.2g stannous octoate, dissolve in 3.2g isopropanol, add 0.8g CaCO 3 The particles were fully stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com