Piercing plug for hot-rolled seamless steel pipe and processing technology thereof

A technology for perforated plugs and seamless steel pipes, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of difficulty in reasonably balancing high temperature strength and toughness, plug failure, and impact on service life, and achieves considerable economic benefits. The effect of reducing production costs and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

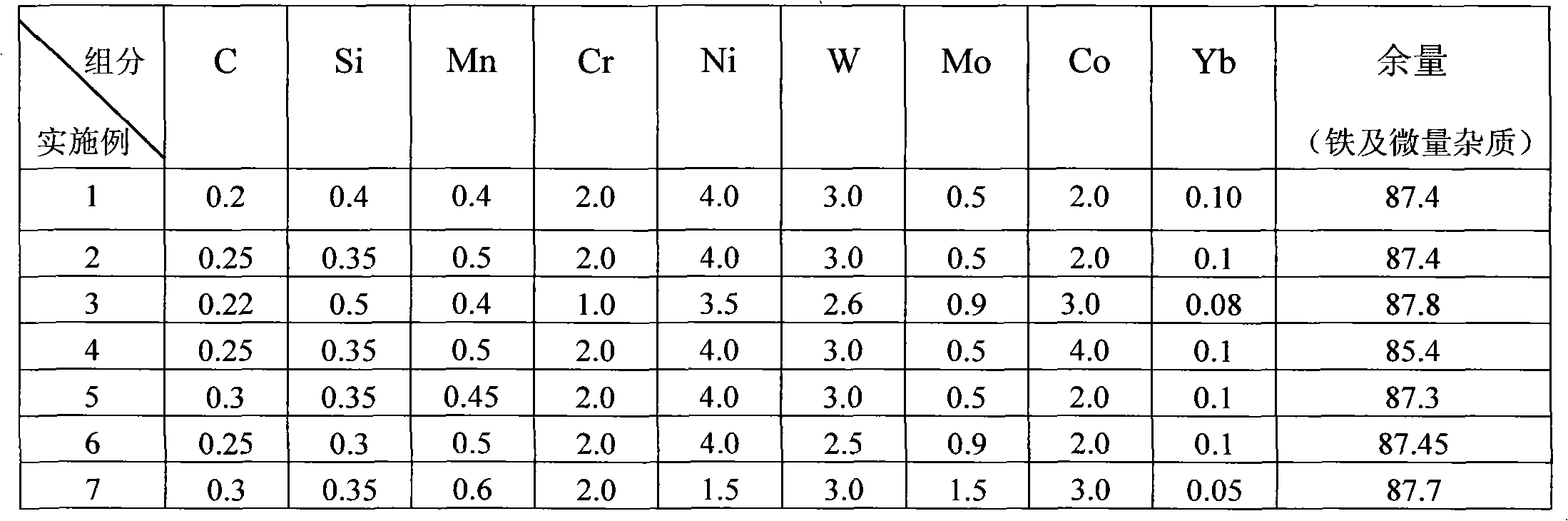

[0027] According to the raw material formula shown in Table 1, it is processed and produced, and processed into a hot-rolled seamless steel pipe perforated plug through batching, hot melting, casting, and heat treatment processes.

[0028] The composition and content (weight %) of hot-rolled seamless steel pipe piercing plug of table 1

[0029]

[0030] According to the specific heat treatment process of the plug processed by batching, hot melting and casting according to the formula of Examples 1-7, the plug is loaded into the furnace when the furnace temperature rises to 900 ° C, the furnace cover is closed, and the plug is dripped into the furnace at a rate of 5 ml / min. Add ethanol, the purpose is to fully burn the air in the furnace, exhaust the air, stop dripping ethanol after 1h, change to ethanol water solution, the volume ratio of described ethanol and water is 1: 4, impel the ethanol water solution and the top surface layer to form Oxidation reaction: raise the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com