Method for rolling and grinding by high pressure roller press for fine chemical engineering and implementing system thereof

A fine chemical and high-pressure roller technology, which is applied in the field of roller press grinding, can solve the problems of not being able to save energy and reduce consumption significantly, serious dust pollution, and low production capacity, and achieve the effects of less equipment maintenance time, less building area, and higher output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

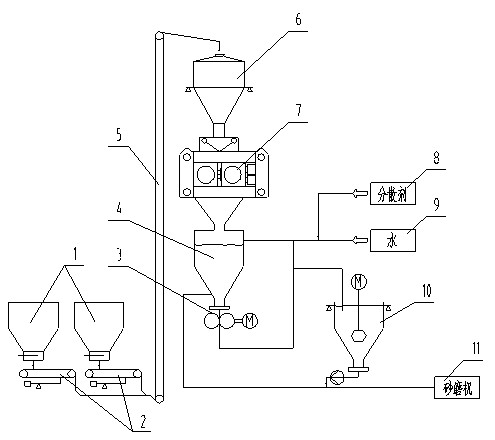

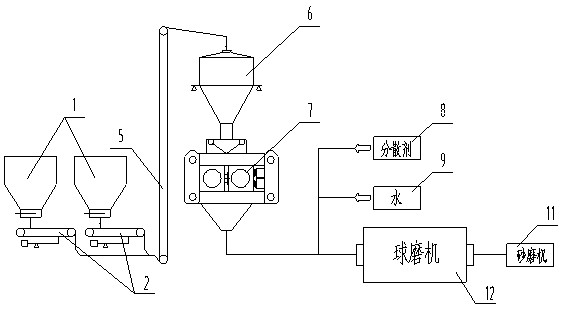

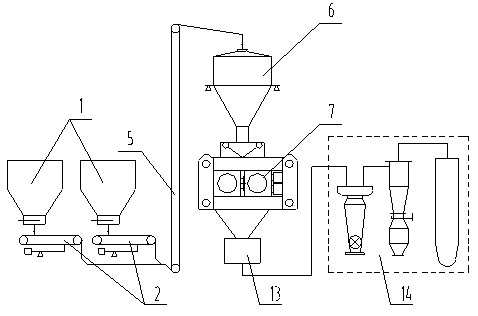

[0024] A specific embodiment of the present invention, a high-pressure roller press grinding method for fine chemical industry, taking the intermediate grinding of titanium dioxide falling kiln products as an example, includes the following steps: titanium dioxide falling kiln products enter the roller through a conveyor Press machine, through the high-pressure action of the roller press, the sheet-like cake is discharged. The roller press used is a high-pressure roller press used in fine chemical industry, which adopts high specific pressure, and the specific pressure is 6.0-10.0Mpa. The roller press used has a wear-resistant and smooth roller surface, which has almost no metal consumption and does not reduce the quality of fine chemical products. The roller press used includes a weighing bin, a hydraulic flap valve and an electric flow regulator to realize the on-off of the material, the flow rate and the balance of the material level, so as to control the processing capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com