Method for preparing novel mesoporous silica nano balls

A nanocrystal, a certain amount of technology, applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., to achieve the effect of easy biocompatibility, simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Use a graduated cylinder to measure 40 mL of diethyl ether (CH 3 OCH 3 ) and 8mLH 2 O was poured into a 100mL sealed round-bottomed flask with a stopper, and magnetically stirred at room temperature to mix evenly;

[0020] (2) Then slowly add 1mL ammonia water (NH 4 OH) and 2mL tetraethyl orthosilicate (TEOS), continue stirring for 3 hours;

[0021] (3) Gradually slowly add 2 mL of TEOS and 1.0 g of cetyltrimethylammonium bromide (CTAB) to the above solution, and slowly stir and react for 5 hours;

[0022] (4) Put the mixed solution of the previous step into a high-pressure reactor, put it in an oven at 120° C., and react for 20 hours;

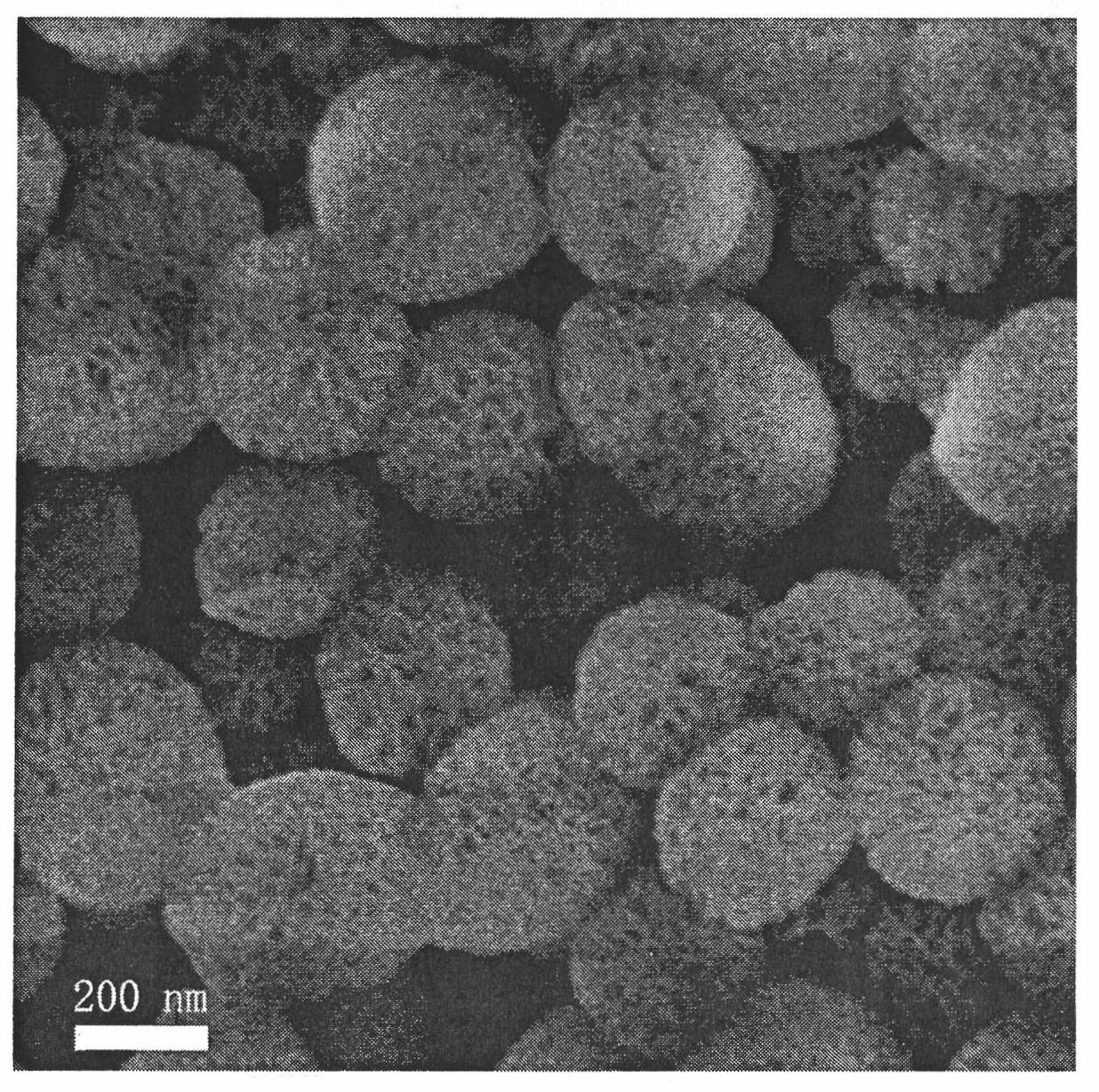

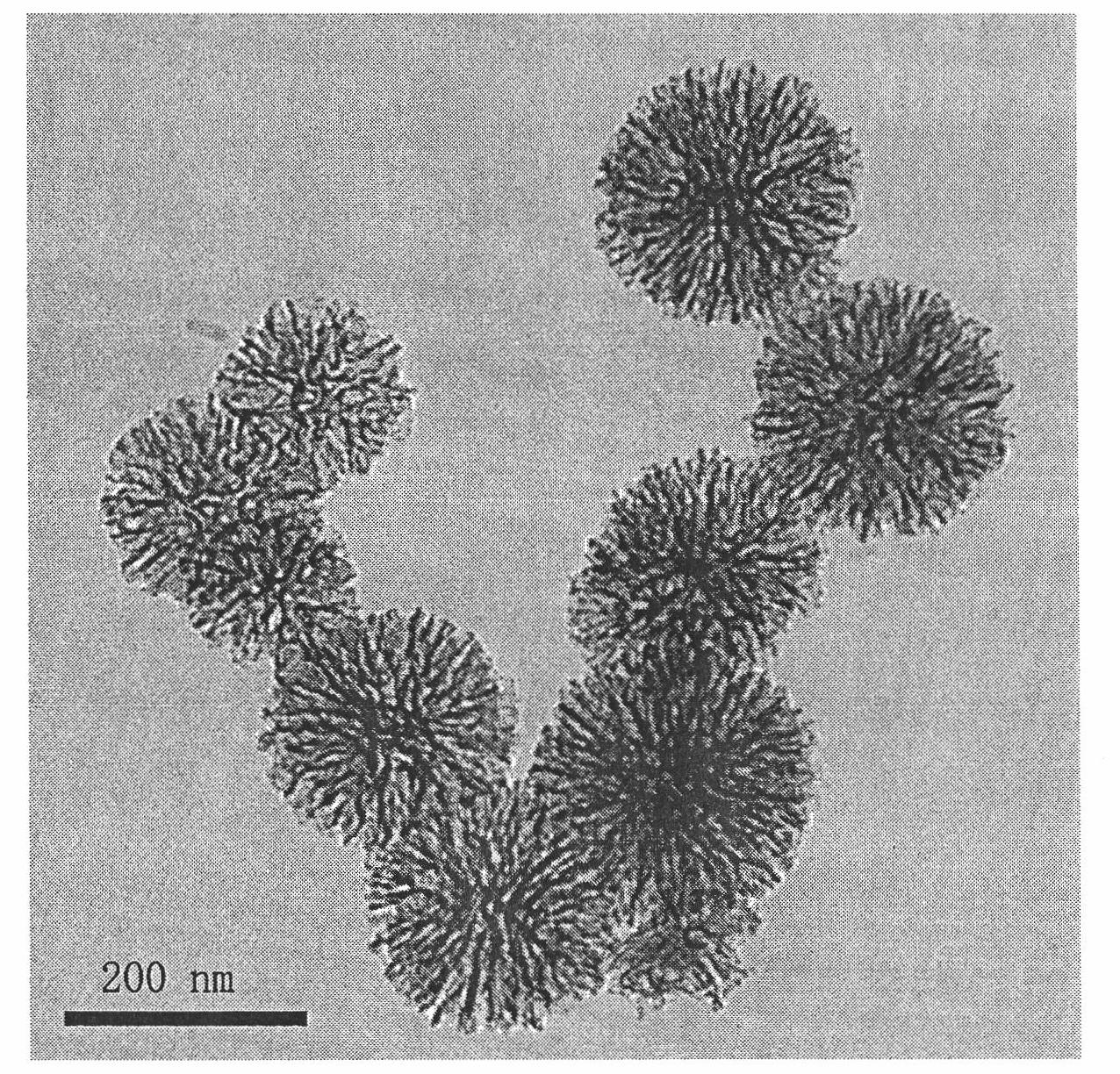

[0023] (5) Take out the mixed solution and wash it repeatedly with distilled water and ethanol, then centrifuge to remove the lower layer of precipitate, and finally place the precipitate in

[0024] Dry in an oven at 60°C to obtain porous SiO 2 nanospheres.

Embodiment 2

[0026] Implementation process step is except following difference, and other is all identical with embodiment 1

[0027] In step (2), slowly add 1 mL of ammonia water (NH 4 OH) and 2mL tetraethyl orthosilicate (TEOS), continue stirring for 1 hour;

[0028] In step (3), slowly add 2 mL of TEOS and 0.8 g of cetyltrimethylammonium bromide (CTAB) to the solution gradually, and slowly stir for 3 hours to react;

[0029] The obtained result is substantially similar to Example 1, except that SiO 2 The diameter of the nanospheres is slightly smaller than that of Example 1.

Embodiment 3

[0031] Implementation process step is except following difference, and other is all identical with embodiment 1

[0032] In step (2), slowly add 1 mL of ammonia water (NH 4 OH) and 1 mL tetraethyl orthosilicate (TEOS), continue to stir and react for 2 hours;

[0033] In step (3), slowly add 1 mL of TEOS and 1.0 g of cetyltrimethylammonium bromide (CTAB) to the solution gradually, and slowly stir for 5 hours;

[0034] The result is substantially similar to Example 1, except that SiO 2 The yield of nanospheres decreased somewhat, and the resulting SiO 2 Nanoballs are a little on the small side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com