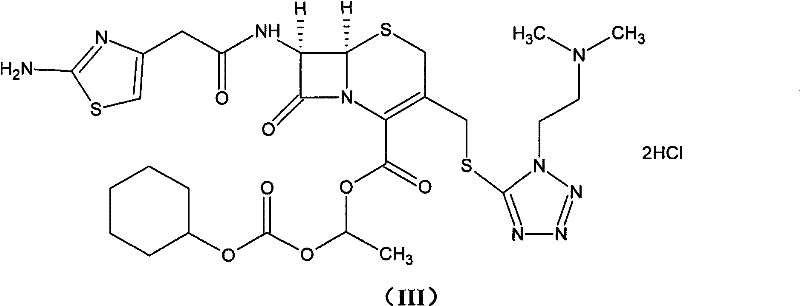

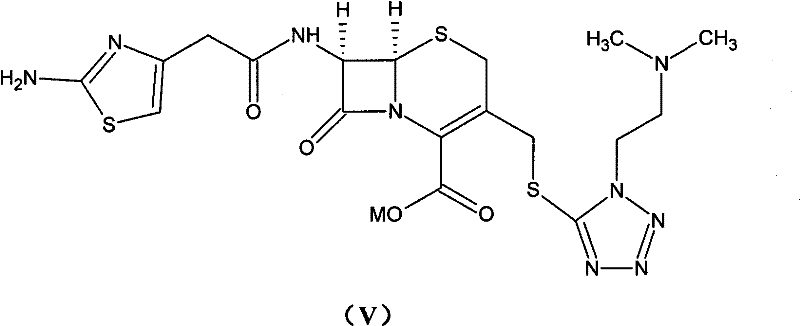

Method for preparing cefotiam hexetil hydrochloride

A technology of cefotiam and cefotiam, which is applied in the field of drug antibiotics and can solve the problems of increasing crystallization loss and increasing separation processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] (1) Add 600L of acetonitrile and 140Kg of pre-dried NaI to the reaction tank, heat to 50°C under stirring, add 130L of 1-chloroethylcyclohexyl carbonate, and react for 100min. After the reaction was completed, it was concentrated to dryness under reduced pressure at room temperature. CH 2 Cl 2 600L and Na 2 S 2 o 3 Aqueous solution (5%) 400L mixed solvent washes concentrate, collects organic layer, obtains the CH of 1-iodide ethyl cyclohexyl carbonate 2 Cl 2 solution.

[0068] (2) Add KHCO to the reaction tank 3 100Kg, water 30L, acetone 60L and stir to dissolve. Then cefotiam 130Kg was added and stirred at 28°C for 40min. Add 1400L of acetone and stir to dissolve, then cool to 0°C, let stand to separate layers and collect the lower layer, then add DMA600L, stir and dissolve at 25°C to obtain cefotiam salt solution.

[0069] (3) CH of 1-iodoethyl cyclohexyl carbonate 2 Cl 2 The solution was added to the cefotiam salt solution and stirred for reaction at a te...

Embodiment 2

[0075] (1) Add 600L of acetonitrile and 140Kg of pre-dried NaI to the reaction tank, heat to 50°C under stirring, add 130L of 1-chloroethylcyclohexyl carbonate, and react for 100min. After the reaction was completed, it was concentrated to dryness under reduced pressure at room temperature. CH 2 Cl 2 600L and Na 2 S 2 o 3 Aqueous solution (5%) 400L mixed solvent washes concentrate, collects organic layer, obtains the CH of 1-iodide ethyl cyclohexyl carbonate 2 Cl 2 solution.

[0076] (2) Add KHCO in the reaction tank 3 100Kg, water 30L, acetone 60L and stir to dissolve. Then cefotiam 130Kg was added and stirred at 28°C for 40min. Add 1700L of acetone and stir to dissolve, then cool to 0°C, let stand to separate layers and collect the lower layer, then add DMA600L, stir and dissolve at 25°C to obtain cefotiam salt solution.

[0077] (3) CH of 1-iodoethyl cyclohexyl carbonate 2 Cl 2 The solution was added to the cefotiam salt solution and stirred for reaction at a temp...

Embodiment 3

[0083] (1) Add 600L of acetonitrile and 140Kg of pre-dried NaI to the reaction tank, heat to 50°C under stirring, add 130L of 1-chloroethylcyclohexyl carbonate, and react for 100min. After the reaction was completed, it was concentrated to dryness under reduced pressure at room temperature. CH 2 Cl 2 600L and Na 2 S 2 o 3 Aqueous solution (5%) 400L mixed solvent washes concentrate, collects organic layer, obtains the CH of 1-iodide ethyl cyclohexyl carbonate 2 Cl 2 solution.

[0084] (2) Add KHCO to the reaction tank 3 100Kg, water 30L, acetone 60L and stir to dissolve. Then cefotiam 130Kg was added and stirred at 28°C for 40min. Add 1700L of acetone and stir to dissolve, then cool to 0°C, let stand to separate layers and collect the lower layer, then add DMA600L, stir and dissolve at 25°C to obtain cefotiam salt solution.

[0085] (3) CH of 1-iodoethyl cyclohexyl carbonate 2 Cl 2 The solution was added to the cefotiam salt solution and stirred for reaction at a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com