Aqueous polyurethane resin and preparation method thereof

A water-based polyurethane and polyester diol technology, which is applied in the field of high-temperature resistant water-based polyurethane resin and its preparation, can solve the problem that the water-based polyurethane resin is not perfect, the high-temperature resistance, water resistance, and alcohol resistance of the water-based polyurethane resin cannot meet the requirements. Water-based polyurethane performance is not ideal and other problems, to achieve excellent high temperature resistance, good alcohol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment one: a kind of aqueous polyurethane resin, preparation method is as follows:

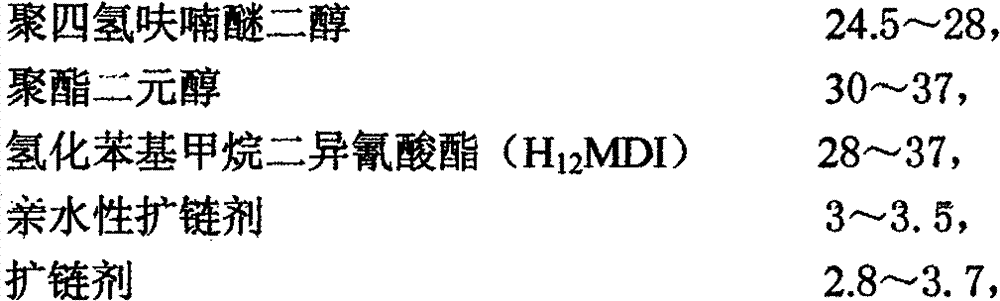

[0040] 1 Prepare materials according to the following components and ratios:

[0041] Polyester diol 1000 molecular weight 50KG, (2000 molecular weight is 100KG), polytetrahydrofuran ether glycol PTMG 1000 molecular weight 40KG, (2000 molecular weight 80KG), TMP 1KG, hydrogenated phenylmethane diisocyanate (H 12 MDI) 60KG, dimethylolpropionic acid DMPA 5KG, 1,4 cyclohexane dimethanol 6KG, or 1,4 butanediol 3KG.

[0042] 2 Raw material mixing, heating, dehydration

[0043] Measure polyester diol and polytetrahydrofuran ether diol, add chain extender trimethylolpropane (TMP), stir the three evenly and heat to 120 degrees, dehydrate under vacuum for 1 hour, and then cool down to 80-95 degrees.

[0044] 3 Prepolymer Synthesis:

[0045] Add hydrogenated phenylmethane diisocyanate (H12MDI) into the diol, control the temperature at 80-95 degrees, stir and react for 2 hours, then add hy...

Embodiment 2

[0050] Embodiment two: a kind of aqueous polyurethane resin, obtains by following preparation method:

[0051] 1 Prepare materials according to the following components and ratios:

[0052] Polyester diol 1000 molecular weight 60KG, (2000 molecular weight is 120KG), polytetrahydrofuran ether glycol PTMG1000 molecular weight, (2000 molecular weight 100KG), TMP 2KG, hydrogenated phenylmethane diisocyanate (H12MDI) 120Kq dimethylol Propionic acid DMPA7.5KG, 1,4 cyclohexane dimethanol 8Kq or 1,4 butanediol 5KG

[0053] 2 Raw material mixing, heating, dehydration

[0054] Measure polyester diol and polytetrahydrofuran ether glycol PTMG, add chain extender trimethylolpropane (TMP), stir the three evenly and heat to 120 degrees, dehydrate under vacuum for 1 hour, then cool down to 80-95 degrees .

[0055] 3 Prepolymer Synthesis:

[0056] Add hydrogenated phenylmethane diisocyanate (H12MDI) into the diol, control the temperature at 80-95 degrees, stir and react for 2 hours, then a...

Embodiment 3

[0061] Embodiment three: a kind of aqueous polyurethane resin, obtains by following preparation method:

[0062] 1 Prepare materials according to the following components and ratios:

[0063] 70KG of polyester diol 1000 molecular weight, (140KG of 2000 molecular weight), 55KG of polytetrahydrofuran ether glycol PTMG1000 molecular weight, (110KG of 2000 molecular weight), TMP 2.5KG, 1, hydrogenated phenylmethane diisocyanate (H 12 MDI) 95KG, dimethylolpropionic acid DMPA 10KG, 1,4 cyclohexanedimethanol 10KG, or 1,4 butanediol 6KG.

[0064] 2 Raw material mixing, heating, dehydration

[0065]Measure polyester diol and polytetrahydrofuran ether glycol PTMG, add chain extender trimethylolpropane (TMP), stir the three evenly and heat to 120 degrees, dehydrate under vacuum for 1 hour, then cool down to 80-95 degrees .

[0066] 3 Prepolymer Synthesis:

[0067] Hydrogenated phenylmethane diisocyanate (H 12 MDI) is added to the glycol, the temperature is controlled at 80-95 degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com