Method for preparing copper nitride film, copper nitride/copper and copper two-dimensional ordered array

A two-dimensional array, copper nitride technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of copper nitride preparation difficulties, etc., and achieve the effect of small lateral diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Formation of Copper Nitride Films on Silicon Substrates by Implanting Copper Films with Nitrogen Ions

[0035] 1. Copper film deposited by sputtering

[0036] Silicon is selected as the substrate, the silicon substrate is cleaned by a standard process, and then a 200nm copper film is deposited on the silicon wafer by radio frequency magnetron sputtering.

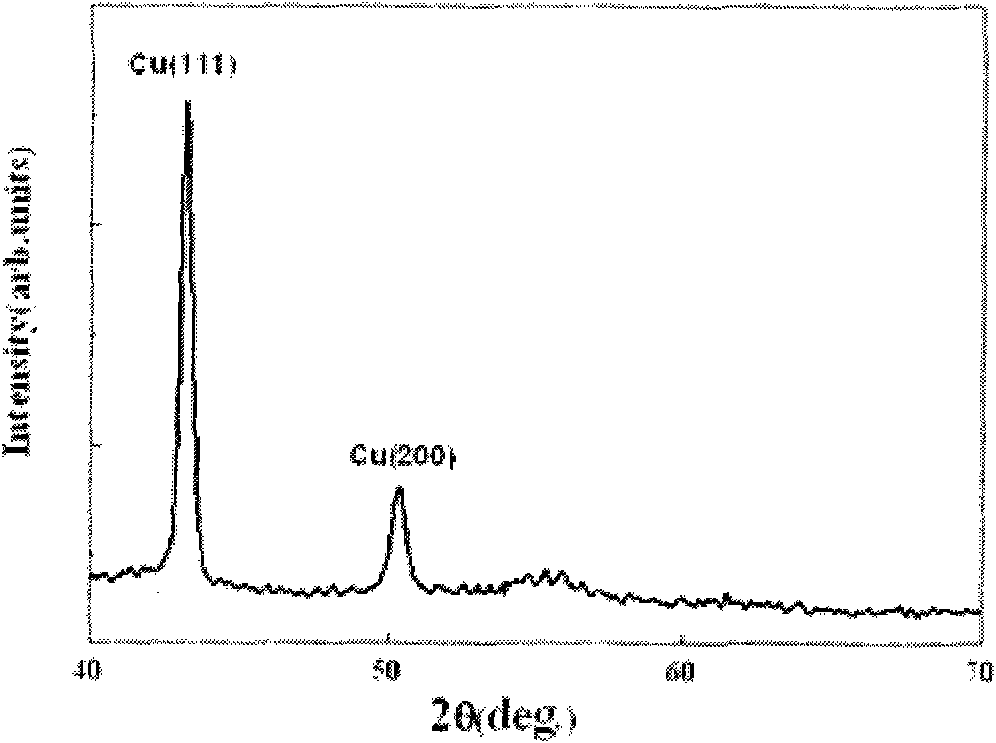

[0037] The background vacuum of the chamber during sputtering is 1×10 -4 Pa, Ar flow rate is 20cm 3 / min, the sputtering pressure is 0.5Pa, the sputtering power is 100W; the distance between the target and the substrate is 6cm. The deposition temperature was 30°C. figure 1 is the XRD pattern of a copper film formed by sputtering on a silicon substrate. The two diffraction peaks in the figure correspond to the (111) and (200) crystal orientations of copper crystals respectively, and have certain preferred orientations. The deposited copper film is polycrystalline.

[0038] 2. Ion implantation of copper film

[0...

Embodiment 2

[0041] Formation of Copper Nitride Films on Silicon Substrates by Implanting Copper Films with Nitrogen Ions

[0042] 1. Copper film deposited by sputtering

[0043] Same as instance 1

[0044] 2. Ion implantation of copper film

[0045] Same as instance 1

[0046] The difference is that the substrate temperature is controlled at 150°C during implantation.

Embodiment 3

[0048] Formation of Copper Nitride Films on Silicon Substrates by Implanting Copper Films with Nitrogen Ions

[0049] 1. Copper film deposited by sputtering

[0050] Same as instance 1

[0051] 2. Ion implantation of copper film

[0052] Same as instance 1

[0053] The difference is that the substrate temperature is controlled at 250°C during implantation.

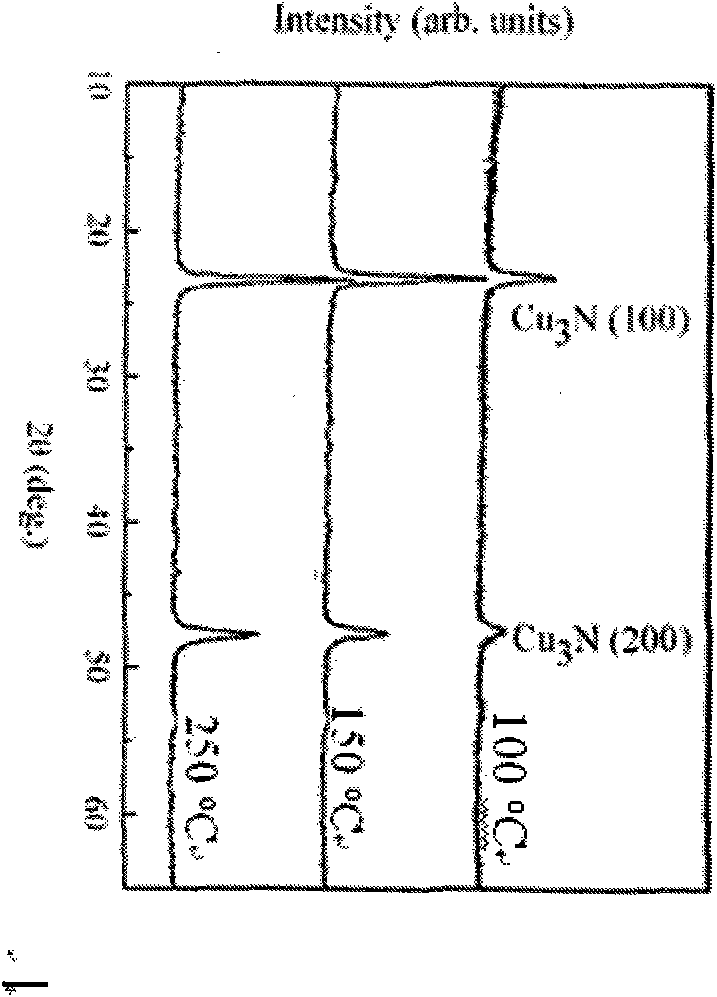

[0054] figure 2 is the XRD pattern of copper nitride. There is a strong diffraction peak, corresponding to Cu 3 The (100) and (200) crystal orientations of N have no obvious diffraction peaks corresponding to Cu, indicating that a copper nitride film has been formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com