Automobile engine cylinder body made of high silicon rare earth aluminum alloy

A technology of automobile engine and aluminum alloy, which is applied in the direction of engine components, machines/engines, cylinders, etc., can solve the problems of reducing the strength and plasticity of high-silicon aluminum alloys, large consumption of lubricating oil, and large friction coefficient, so as to improve lubrication performance, Low manufacturing cost and low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

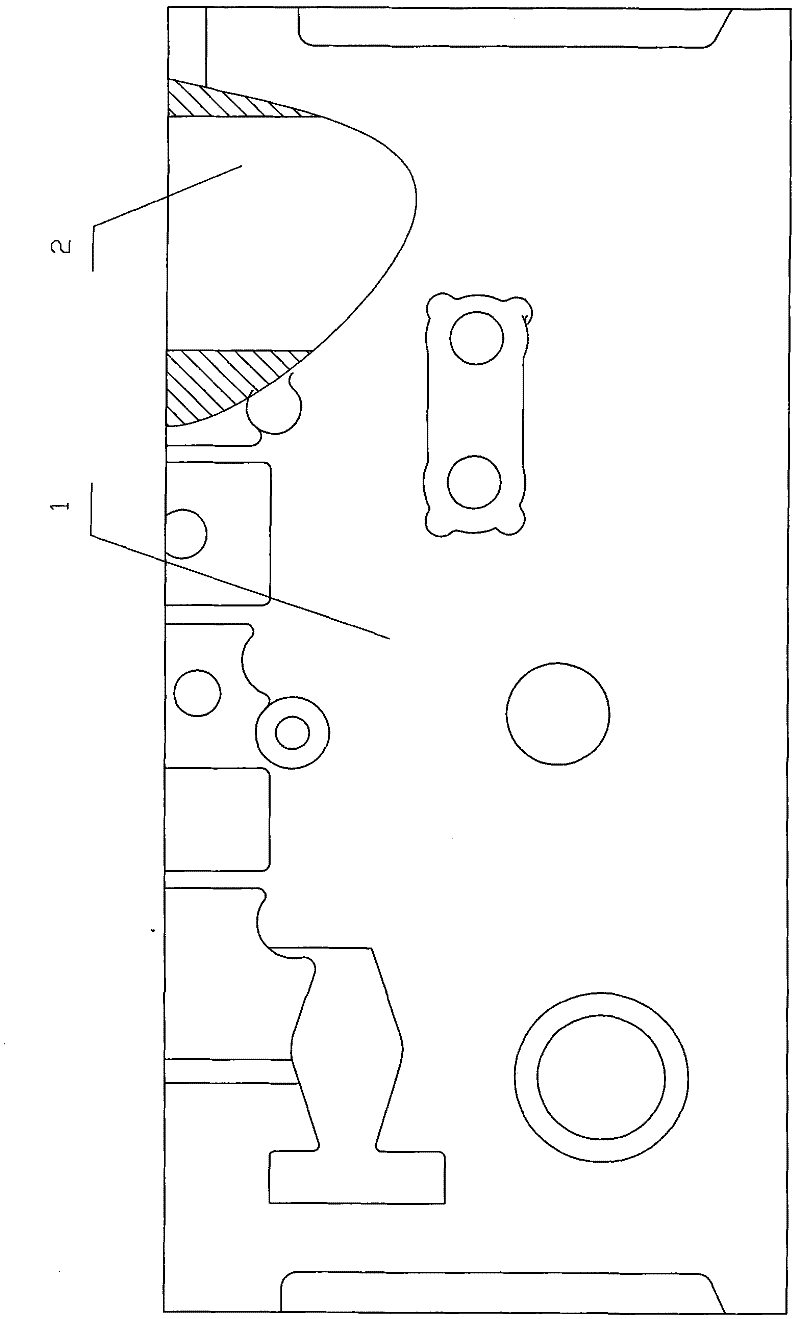

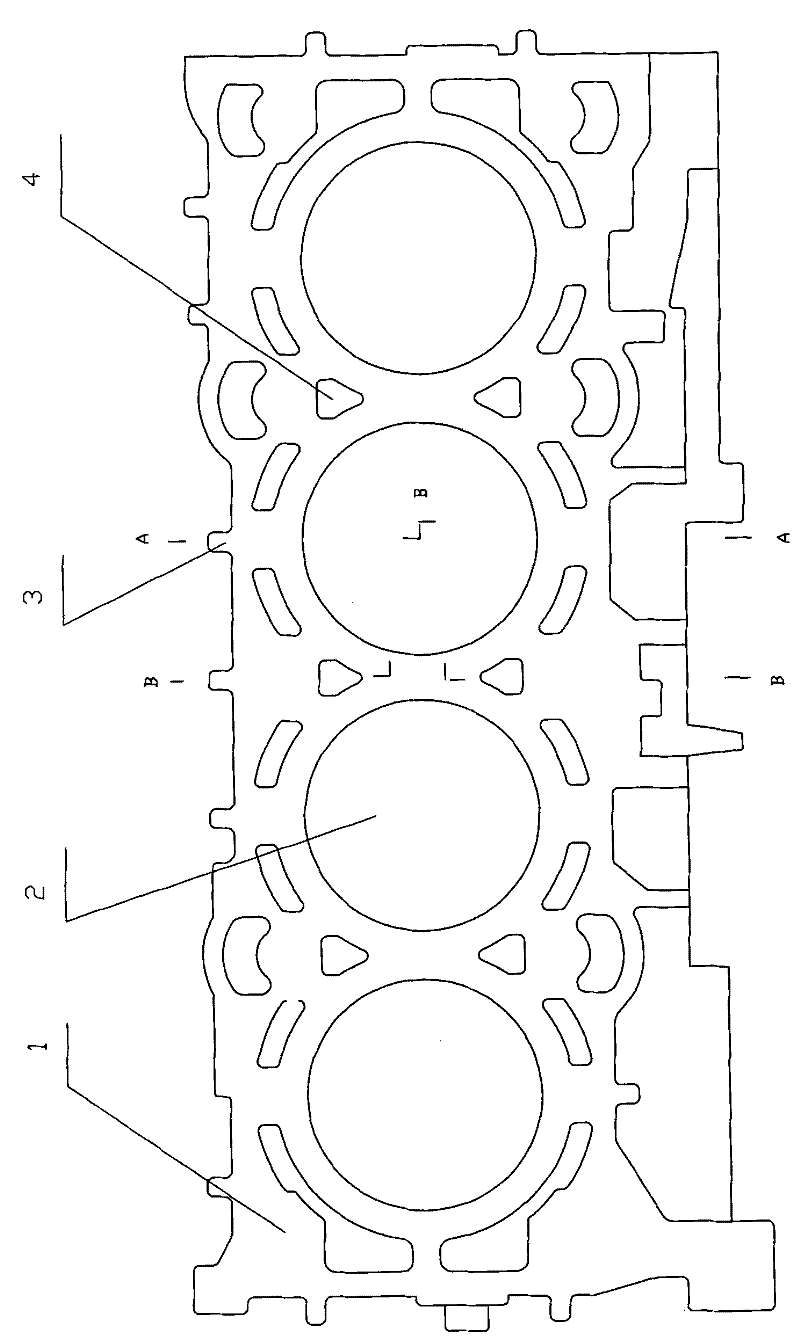

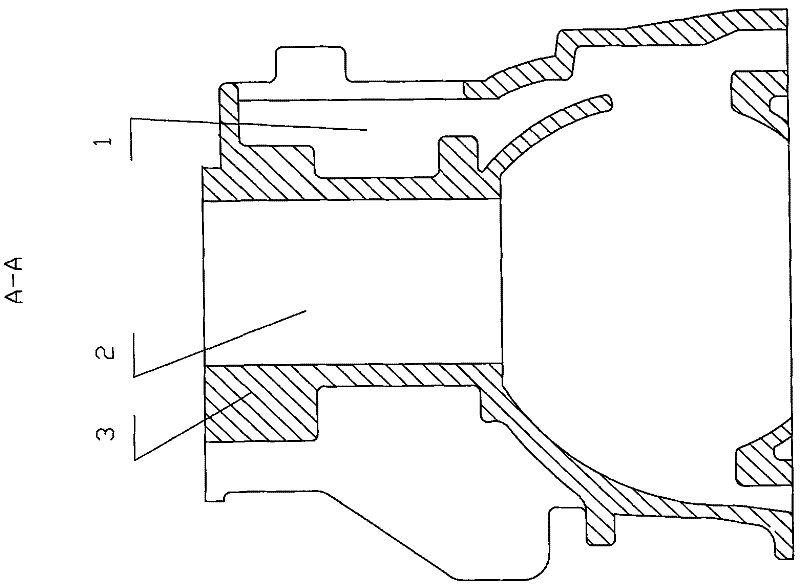

[0038] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

[0039] As shown in the accompanying drawings, the technical solution adopted by the present invention is to provide a cylinder 2 on the cylinder 1, and the cylinder 1, cylinder 2 and inner wall 5 of the cylinder are integrally cast with the same high-silicon rare earth aluminum alloy material. This structure makes the present invention neither need additional casting of the cylinder liner, nor need to add a coating on the inner wall 5 of the cylinder, and the cylinder as a whole has consistent high strength, hardness and wear resistance;

[0040] The high-silicon rare earth aluminum alloy is composed as follows by weight percentage:

[0041] Silicon 19.0~21.0%,

[0042] Copper 3.5~4.3%,

[0043] Magnesium 0.5~0.7%,

[0044] Iron 0.82~0.88%,

[0045] Zinc 0.55~0.70%,

[0046] Manganese 0.2~0.4%,

[0047] Nickel 0.03~0.08%,

[0048] Titanium 0.1~0.2%,

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com