Decompressed purge-and-trap processing equipment for non-volatile organic compound in water sample and processing method thereof

A non-volatile, purge and trap technology, applied in the field of chromatography, can solve the problems of many intermediate steps, long time required, secondary pollution, etc., and achieve the effect of short cycle, easy automation, and less manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take the determination of acenaphthylene content in water by vacuum purge and trap as an example:

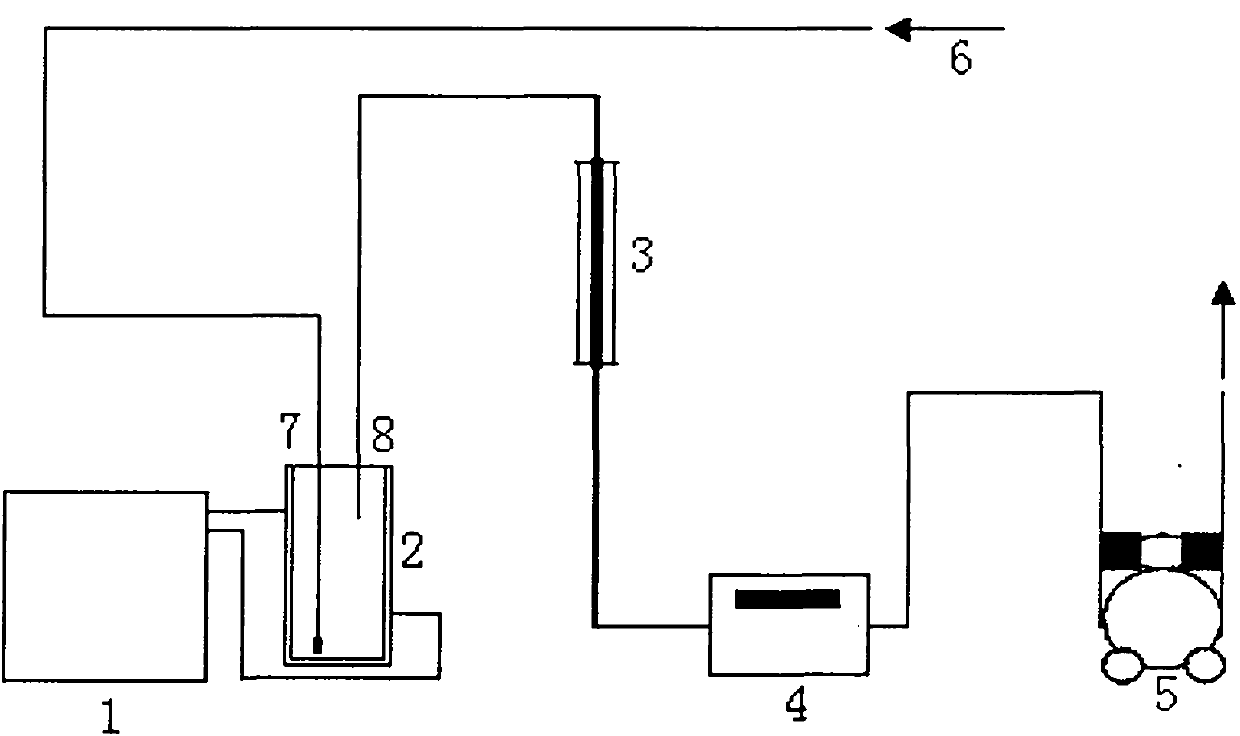

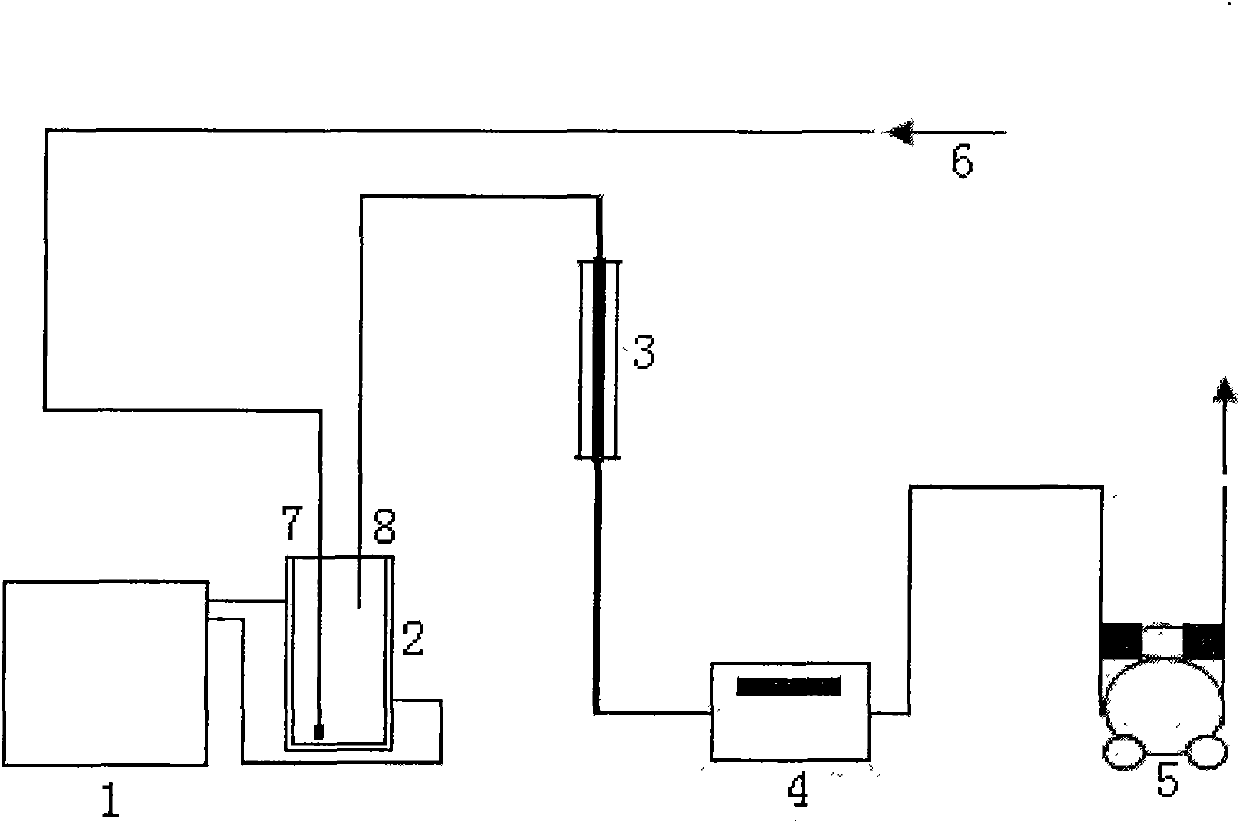

[0032] The decompression purging and trapping treatment device for non-volatile organic compounds in water samples is composed of a sample heater 1, a purge bottle 2, a trap 3, a pressure controller 4 and a pump 5 in sequence, and the purge gas 6 passes through the purge The gas inlet 7 is connected to the purge bottle 2 , the purge bottle is connected to the trap 3 through the purge gas outlet 8 , and the trap 3 is connected to the pump 5 through the pressure controller 4 .

[0033] The trap 3 traps the gas and takes it out and puts it into the heater 13 of the trap. The chromatographic carrier gas 14 is connected to the chromatographic inlet 12 in the column thermostat 11 through the transfer line 15 after analyzing the target object through the trap 3 , the chromatographic inlet is connected to the chromatographic detector 9 through the chromatographic column 10 .

[...

Embodiment 2

[0049] Adopt the device of embodiment 1, analyze the method for benzo [a] anthracene, chrysene, benzo [a] pyrene, benzo [b] fluoranthene in a certain water sample:

[0050] 1. Standard solution preparation

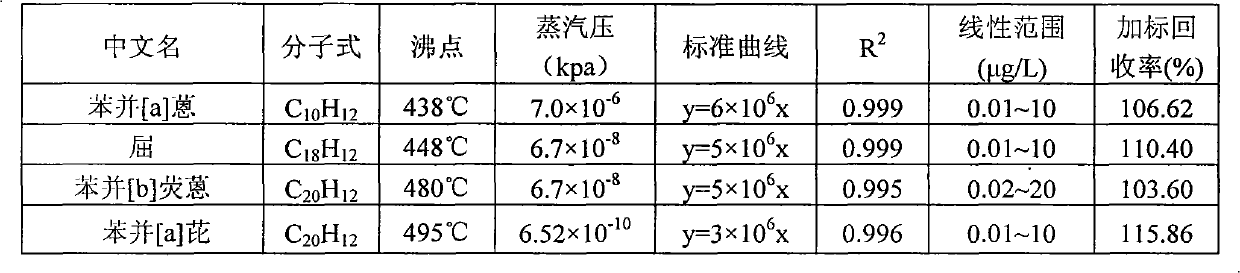

[0051] (1) Prepare the mixed standard solutions of the above four polycyclic aromatic hydrocarbons with concentrations of 0.01 μg / L, 0.1 μg / L, 1.0 μg / L, and 10.0 μg / L, wherein the standard concentrations of benzo[b]fluoranthene are respectively 0.02μg / L, 0.2μg / L, 2.0μg / L, 20.0μg / L, see Table 1 for their properties.

[0052] (2) Add 10 mL of water from the above standard into a 20 mL headspace bottle, and seal the headspace bottle.

[0053] 2. Gas connection

[0054] With embodiment 1.

[0055] 3. Purge and trap method

[0056] The sample heating temperature is set to 80°C, the pressure of the whole closed system is controlled at 20kpa through the pump and the pressure controller, the trapping material is polyacrylate (PA) solid-phase microextraction needle with a film ...

Embodiment 3

[0062] Using the device of Example 1, analyze benzo[k]fluoranthene, benzo(g, h, i) perylene, indeno[1,2,3-cd] perylene, dibenzo(a, h) in water samples ) method of anthracene:

[0063] 1. Standard solution preparation

[0064] (1) Prepare mixed standard solutions of the above four polycyclic aromatic hydrocarbons with a concentration of 0.01 μg / L, 0.1 μg / L, 1.0 μg / L, and 10.0 μg / L, in which the standard of benzo(g, h, i) perylene The concentrations are 0.02μg / L, 0.2μg / L, 2.0μg / L, and 20.0μg / L respectively, and their properties are shown in Table 2.

[0065] (2) Add 10 mL of water from the above standard into a 20 mL headspace bottle, and seal the headspace bottle.

[0066] 2. Gas connection

[0067] With embodiment 1.

[0068] 3. Purge and trap method

[0069] Set the sample heating temperature to 90°C, control the pressure of the entire closed system at 5kpa through a pump and a pressure controller, and use polyacrylate (PA) solid-phase microextraction needles with a film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com