Process for the preparation of titanium dioxide with nanometric dimensions and controlled shape

一种纳米、尺寸的技术,应用在染料敏化太阳能电池领域,能够解决没有提供二氧化钛、不适于生产锐钛矿相纳米棒、不能类似地分离等问题,达到降低生产费用、易于实现工业化规模的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

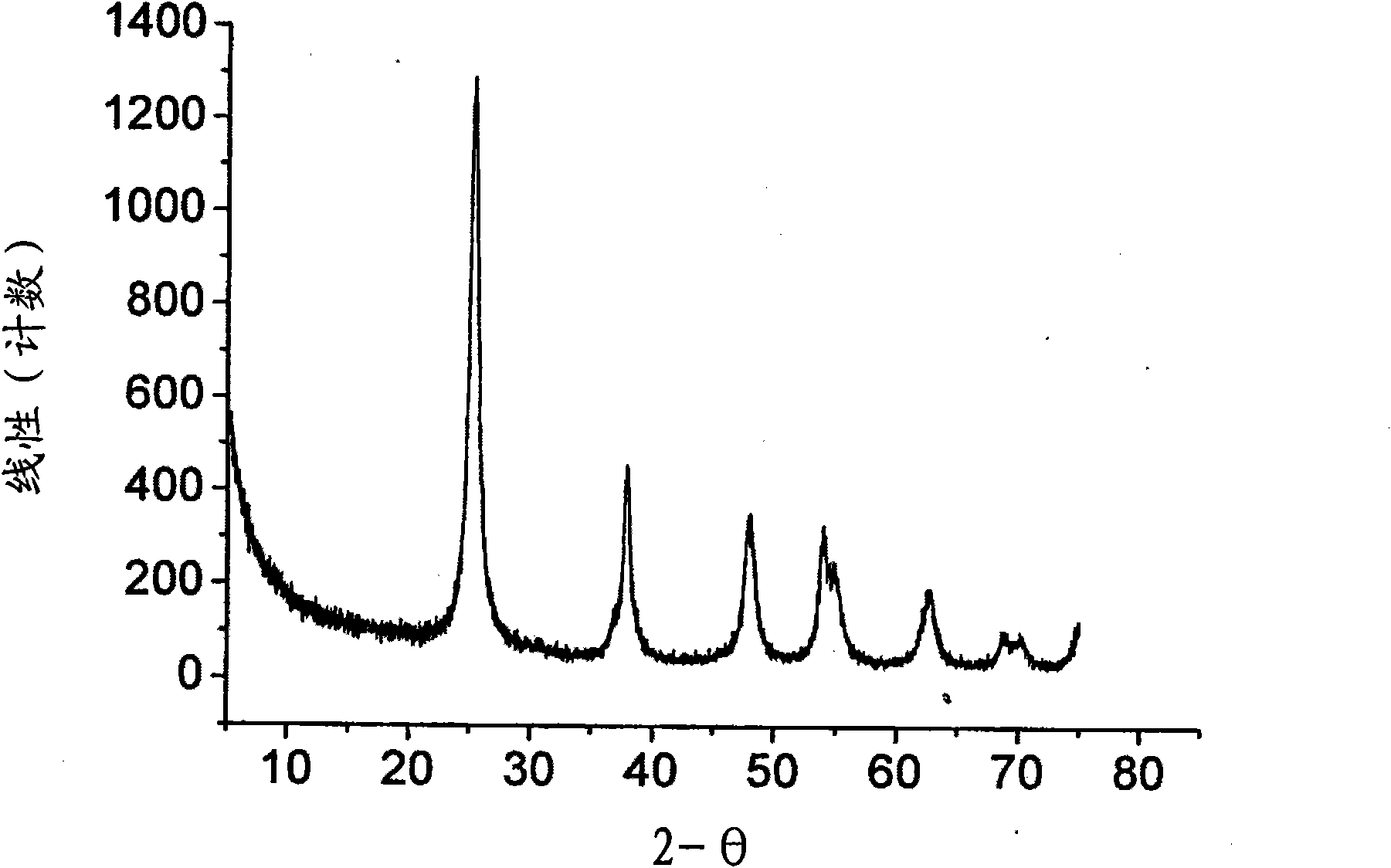

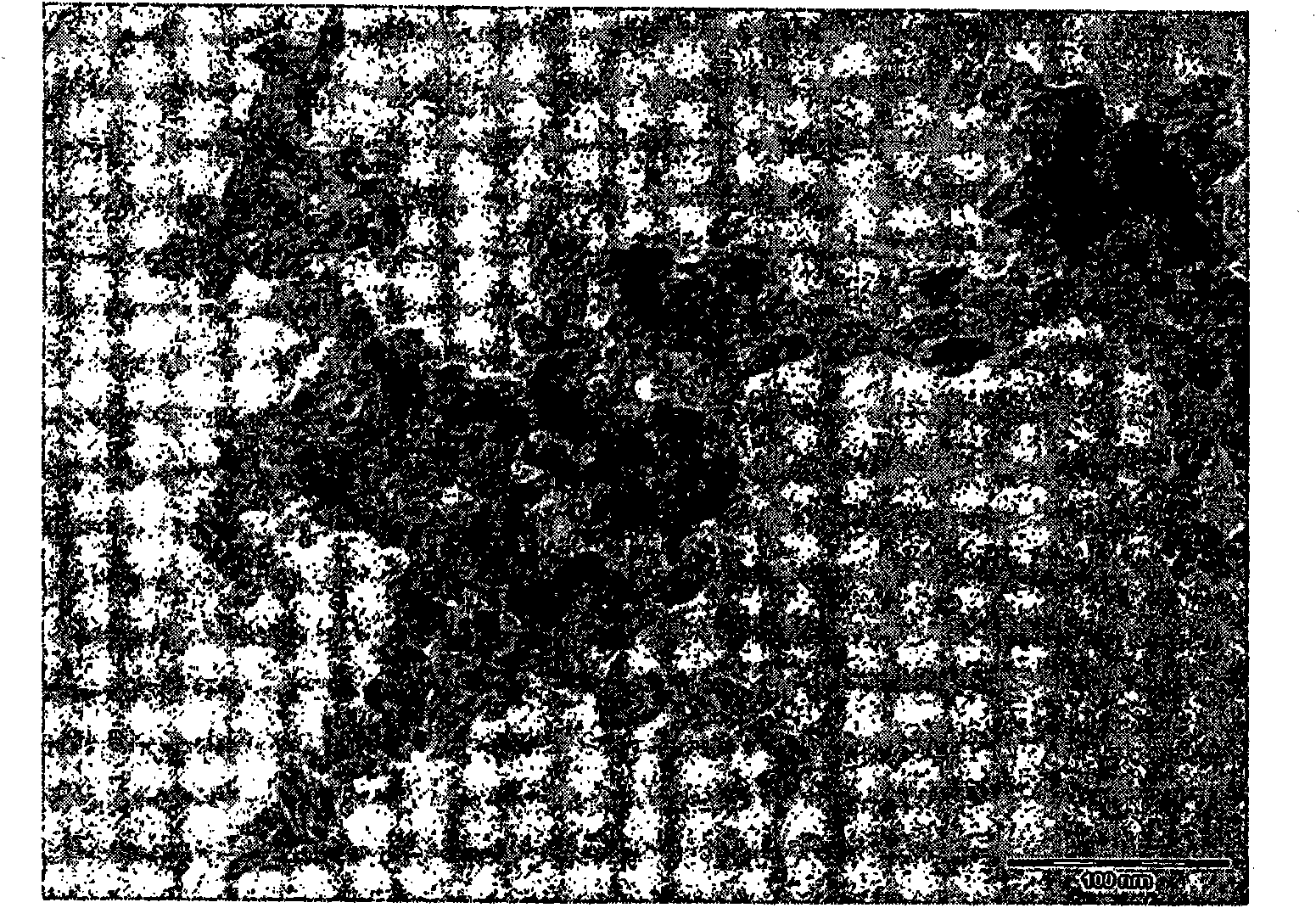

[0081] Benzyl alcohol (403 g; 3.88 moles), acetic acid (90 g; 1.51 moles) and titanium tetraisopropoxide (106.7 g; 0.375 moles) were mixed by mechanical stirring in a 1000 ml flask equipped with a bubble condenser at room temperature. The mixture was heated to a reflux temperature of around 110°C. After 5 hours, the solution became cloudy and tended to gradually thicken. The stirring speed was increased and the mixture was kept at reflux for about 24 hours. The suspension turned into a liquid, which showed an intense white color. The mixture was transferred to a flask and concentrated in vacuo (0.5 mmHg) at about 70°C until a sticky paste formed. The residue obtained was washed with ethanol followed by diisopropyl ether, then filtered and dried at low pressure to give TiO 2 (26.5 g), characterized by XRPD (Figure Ia) and TEM (Figure Ib).

Embodiment 2

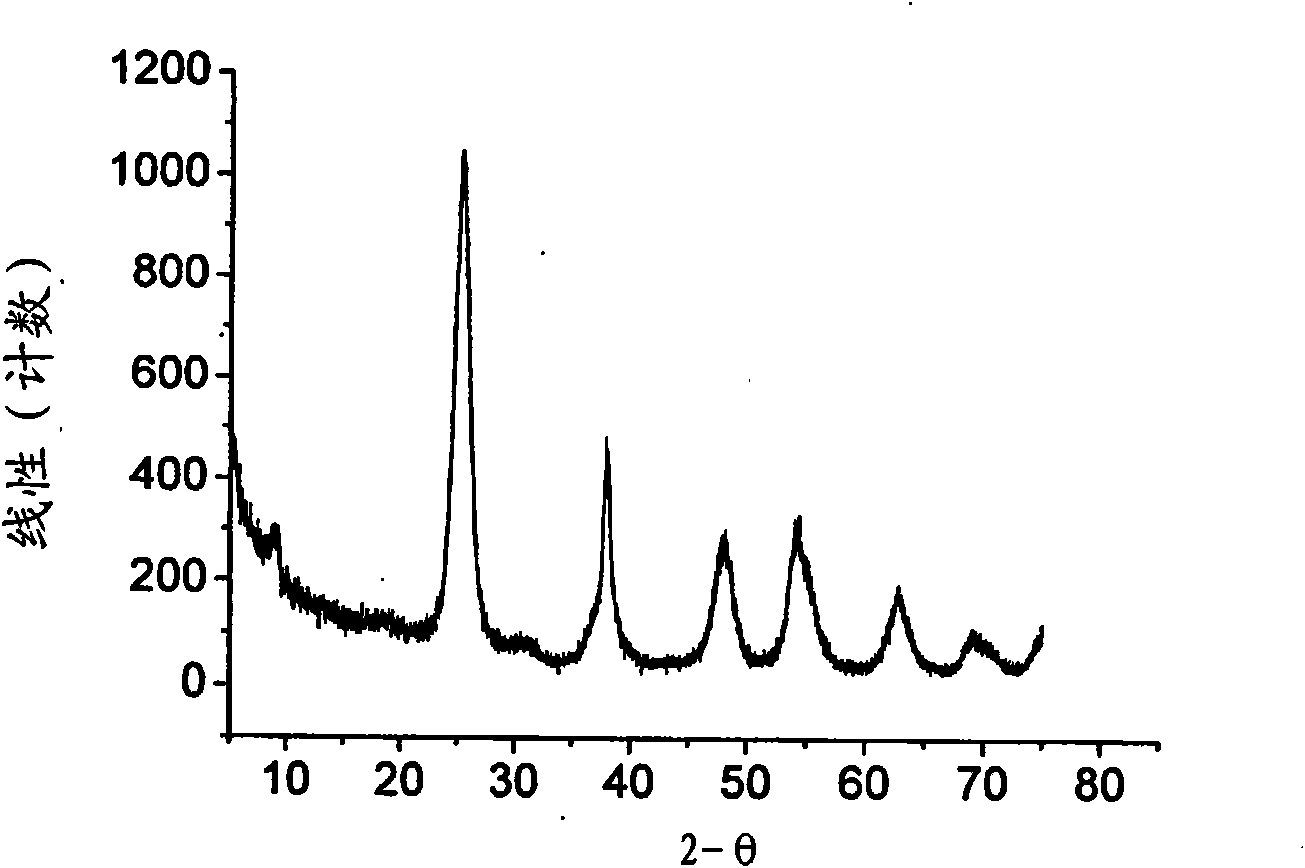

[0083] Following the same procedure as Example 1, but using benzoic acid (184 g, 1.15 moles) instead of acetic acid, TiO 2 (26.5 g), characterized by XRPD (Figure 2a) and TEM (Figure 2b).

Embodiment 3

[0085] Using the same procedure as Example 1, but using oleic acid (76.26 g, 0.27 moles) instead of acetic acid, TiO 2 (26.5 g), characterized by XRPD (Figure 3a) and TEM (Figure 3b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com