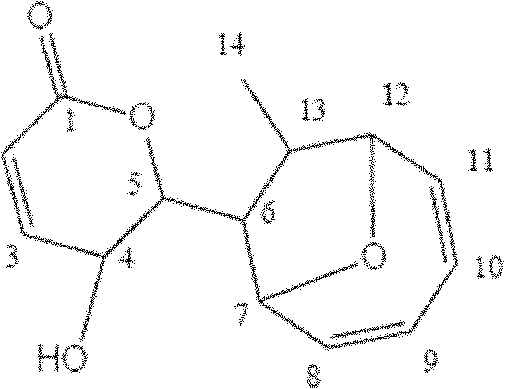

Antineoplastic compound deacetylase fungus epoxy ethyl ester injection and preparation method thereof

A technology of ethylene oxide injection and ethylene oxide, which is applied in the field of compounds, can solve the problem of insoluble ethylene oxide of deacetylated fungi, reduce the volume of administration and toxic and side effects, have high drug solubility, and be easy to transport Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

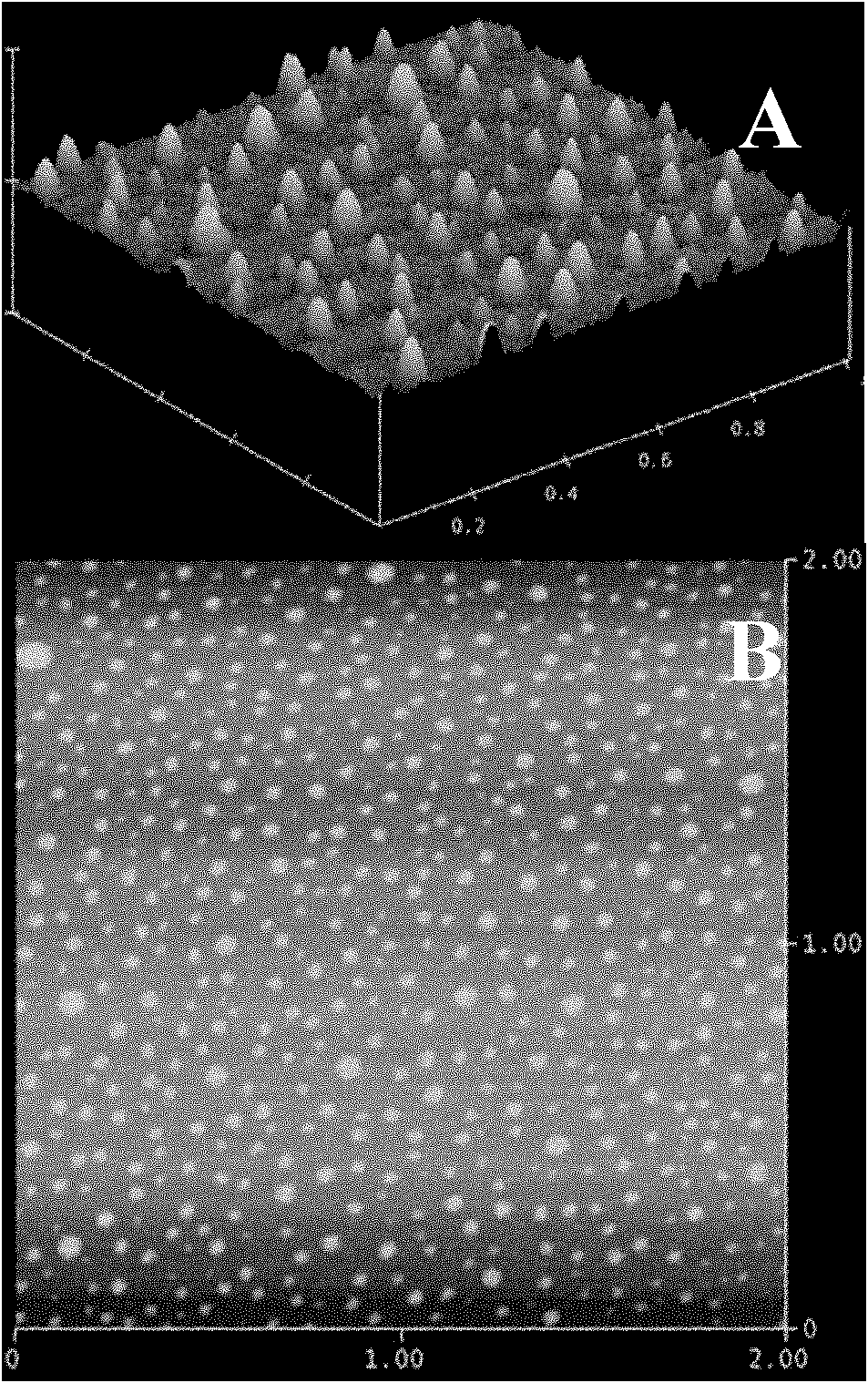

Image

Examples

Embodiment 1

[0023] Example 1: Weigh 1 g of deacetylated fungal oxirane, 1880.5 g of poloxamer, 0.5 g of lecithin, and 0.3 g of hydroxypropyl methylcellulose, put them in a 200 ml beaker, measure 100 ml of distilled water, and add them to the beaker , high-speed shearing machine 15000rpm pre-dispersion 2min. Use a high-pressure homogenizer to homogenize 3 times at pressures of 500 bar and 1000 bar respectively, and then homogenize 5 times at a pressure of 1200 bar. Weigh 3g of mannitol, add it to the above solution, stir to dissolve, divide into vials, 2ml per bottle, freeze in -80°C ultra-low temperature refrigerator for 24 hours, take it out and put it into a freeze-dried product whose temperature has dropped to -50°C Put it on the shelf of the machine, cover it with a vacuum cover, turn on the switch of the vacuum pump, and freeze-dry for 48 hours. After the freeze-drying is finished, take out the pressurized aluminum cap and pack it for storage, and then obtain the anti-tumor compound...

Embodiment 2

[0024] Example 2: Weigh 1 g of acetylated fungal oxirane, 1 g of lecithin, and 0.3 g of hydroxypropyl methylcellulose, place them in a 200 ml beaker, measure 100 ml of distilled water, add them to the beaker, and pre-disperse with a high-speed shearing machine at 15000 rpm 2min. Use a high-pressure homogenizer to homogenize 3 times at pressures of 500 bar and 1000 bar respectively, and then homogenize 5 times at a pressure of 1200 bar. Weigh 3g of lactose, add it to the above solution, stir to dissolve, divide into vials, 2ml per bottle, freeze in -80°C ultra-low temperature refrigerator for 24 hours, take it out and put it into a freeze dryer whose temperature has dropped to -50°C On the shelf, cover with a vacuum cover, turn on the vacuum pump switch, and freeze-dry for 48 hours. After the freeze-drying is finished, take out the pressurized aluminum cap and pack it for storage, and then obtain the anti-tumor compound deacetylated fungus ethylene oxide injection.

Embodiment 3

[0025] Embodiment 3: Weigh 1 g of ethylene oxide ester of deacetylated fungi, 1881 g of poloxamer, and 300.3 g of povidone K, and place them in a 200 ml beaker, measure 100 ml of distilled water, add them to the beaker, and pre-disperse with a high-speed shearing machine at 15000 rpm 2min. Use a high-pressure homogenizer to homogenize 3 times at pressures of 500 bar and 1000 bar respectively, and then homogenize 5 times at a pressure of 1200 bar. Weigh 3g of mannitol, add it to the above solution, stir to dissolve, divide into vials, 2ml per bottle, freeze in -80°C ultra-low temperature refrigerator for 24 hours, take it out and put it into a freeze-dried product whose temperature has dropped to -50°C Put it on the shelf of the machine, cover it with a vacuum cover, turn on the switch of the vacuum pump, and freeze-dry for 48 hours. After the freeze-drying is finished, take out the pressurized aluminum cap and pack it for storage, and then obtain the anti-tumor compound deace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com