Desorbing method and device of absorption rich liquor for absorbing sulfur dioxide by using citrate solution

A technology of sulfur dioxide and citrate, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of environmental pollution, process cost reduction, high concentration of sulfate radicals and citric acid decomposition products, and achieve desorption. High efficiency, improving desorption side reactions, and suppressing desorption side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

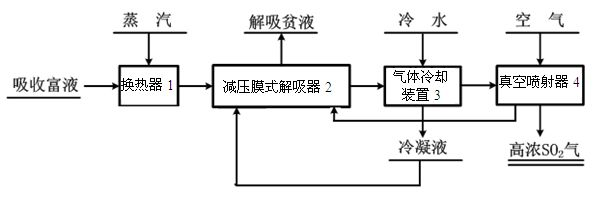

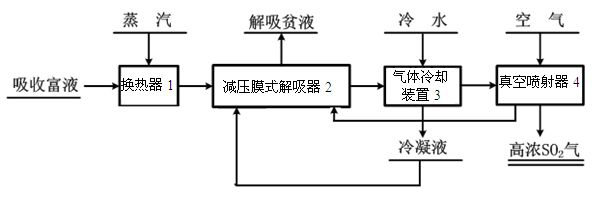

[0020] like figure 1 As shown, a heat exchanger 1, a decompression membrane desorber 2, a gas cooling device 3 and a vacuum ejector 4 are arranged in sequence; wherein, the heat exchanger 4 is used to absorb rich liquid and exchange heat with steam, and the membrane desorber 2 is used to absorb the rich liquid for desorption, the gas cooling device 3 is used to separate sulfur dioxide from steam, and the vacuum ejector 4 is used to generate negative pressure;

[0021] Citrate absorption liquid with sodium citrate / potassium as absorbent to make it absorb low concentration SO in a packed tower 2 , to obtain the absorption rich solution with a citrate concentration of 0.1mol / L and a sulfurous acid concentration of 10g / L, heat exchange through the heat exchanger 1, and then send it into the membrane desorber 2 for rich solution desorption; the membrane desorber 2 Utilize the negative pressure gas produced by vacuum ejector 4 to provide decompression operating conditions for membr...

Embodiment 2

[0023] like figure 1 Shown, device is arranged with embodiment 1.

[0024] Citrate absorption liquid with sodium citrate / potassium as absorbent to make it absorb low concentration SO in a packed tower 2 , to obtain the absorption rich solution with a citrate concentration of 1.0mol / L and a sulfurous acid concentration of 80g / L, heat exchange through the heat exchanger 1, and then send it into the membrane desorber 2 for rich solution desorption; the membrane desorber 2 The negative pressure gas produced by vacuum ejector 4 provides decompression operating conditions for membrane desorber 2. The operating conditions are as follows: the pressure is 1.5MPa, and the operating temperature is 45°C; the desorption temperature of membrane desorber 2 is 90°C. The pressure is 0.70atm, the desorption time is 10 minutes, and the desorption rate is higher than 98%. After the desorption is completed, the desorption gas passes through the gas cooling device 3 to separate the sulfur dioxide ...

Embodiment 3

[0026] like figure 1 Shown, device is arranged with embodiment 1.

[0027] Citrate absorption liquid with sodium citrate / potassium as absorbent to make it absorb low concentration SO in a packed tower 2 , to obtain the absorption rich solution with a citrate concentration of 2.0mol / L and a sulfurous acid concentration of 140g / L, heat exchange through the heat exchanger 1, and then send it into the membrane desorber 2 for rich solution desorption; the membrane desorber 2 Utilize the negative pressure gas produced by the vacuum ejector 4 to provide decompression operating conditions for the membrane desorber 2, the operating conditions are as follows: the pressure is 3.0MPa, the operating temperature is 60°C, the desorption temperature of the membrane desorber 2 is 100°C, and the desorption pressure 0.60atm, the desorption time is 10 minutes, and the desorption rate is higher than 98%. After the desorption is completed, the desorption gas passes through the gas cooling device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com