Dual composite high strength and toughness block amorphous alloy and preparation method thereof

An amorphous alloy and high-strength technology, which is applied in the field of amorphous composite materials and its preparation, can solve the problems of not being able to prepare double-composite amorphous composite materials, and achieve improved interface wetting conditions, simulated interface reactions, and dense structures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

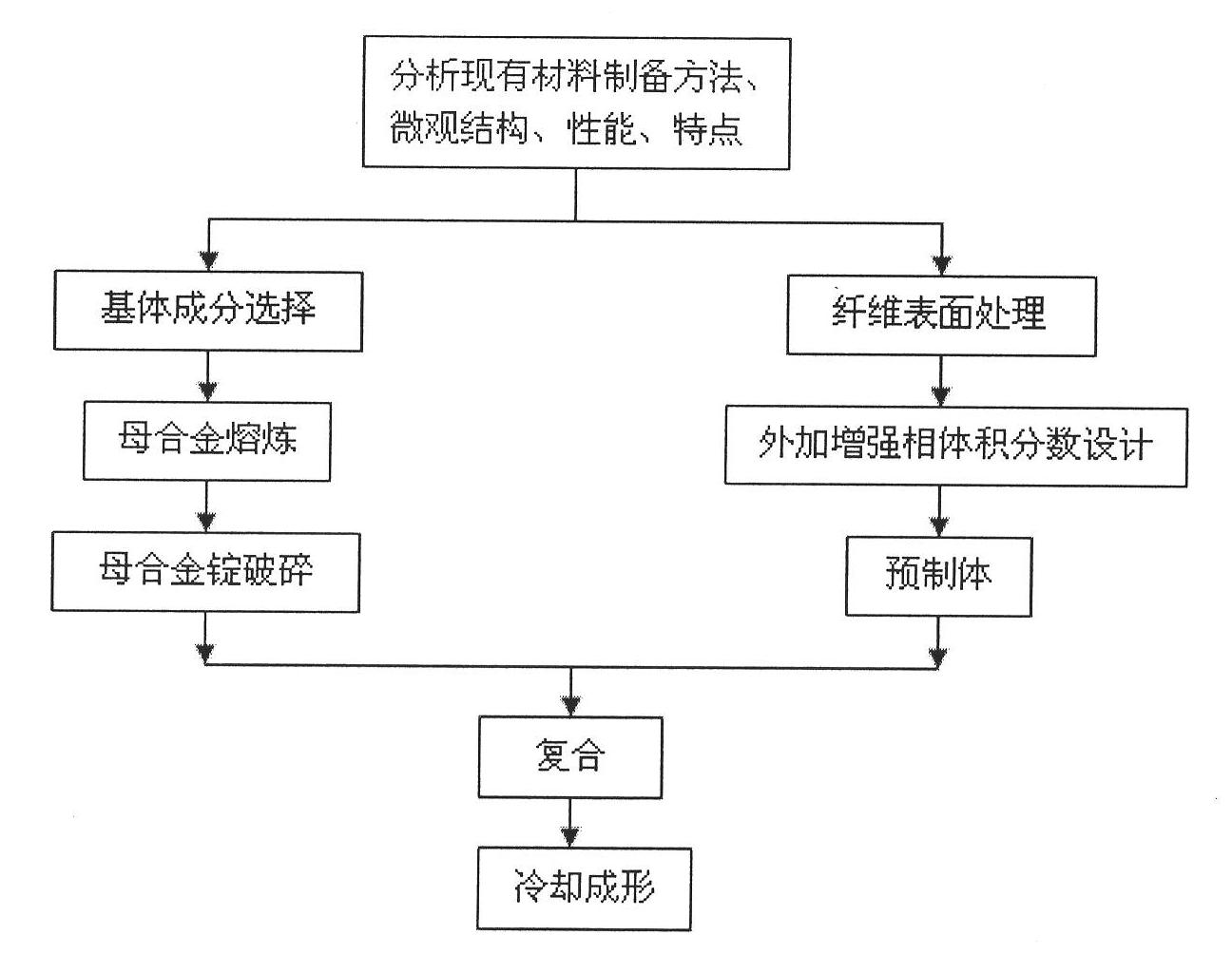

[0020] A method for preparing a dual-composite high-strength and tough bulk amorphous alloy of the present invention comprises the following steps:

[0021] In the first step, the matrix composition of the Zr-Ti-Nb-Cu-Ni-Be master alloy is selected to deviate from the eutectic point, and it is melted into a master alloy ingot by arc melting; or the Mg-TM-RE-Zn alloy is selected as the matrix phase , add an element to the matrix phase alloy, the formation enthalpy of the compound of this element and the main element Mg is positive, and the enthalpy with TM in the alloy is negative, and the high melting point components TM and RE are prepared into an intermediate alloy by arc melting, and the intermediate The alloy is crushed and put into the container together with the low melting point components Mg and Zn, and the master alloy is made by induction melting;

[0022] In the second step, the surface-treated continuous fiber is cut into small sections, straightened, and loaded in...

Embodiment 1

[0044] (1) Selection of matrix alloy composition

[0045] The purity of each metal component selected for preparing the master alloy ingot is shown in Table 1, and the nominal composition of the alloy is Zr56.2Ti13.8Nb5.0Cu6.9Ni5.6Be12.5 (atomic percentage).

[0046] Table 1 Purity of selected metal components for preparing master alloy ingots (%)

[0047]

[0048] (2) Preparation of master alloy ingot

[0049] Under the conditions of Ti inhalation and high-purity argon protection, master alloy buckle ingots were melted in a non-consumable arc melting furnace.

[0050] The specific procedure for the preparation of master alloy buckle ingots is as follows:

[0051] After the surface of the metal raw material is mechanically polished to remove the oxide skin on the surface, the ingredients are proportioned according to the designed composition; the weighing is accurate to within 0.005g, and the prepared material is put into the melting furnace according to the weight of abo...

Embodiment 2

[0059] The composition of the matrix alloy is Zr60Ti14.67Nb5.33Cu5.56Ni4.44Be10 (atomic percentage), and the additional reinforcing phase is W fiber with a diameter of 0.28mm, and the volume fraction is 65%. Step 3 of Example 1 is the same, except that the holding temperature is 950°C, the holding time is 30 minutes, and the pressure of infiltration casting is 2MPa.

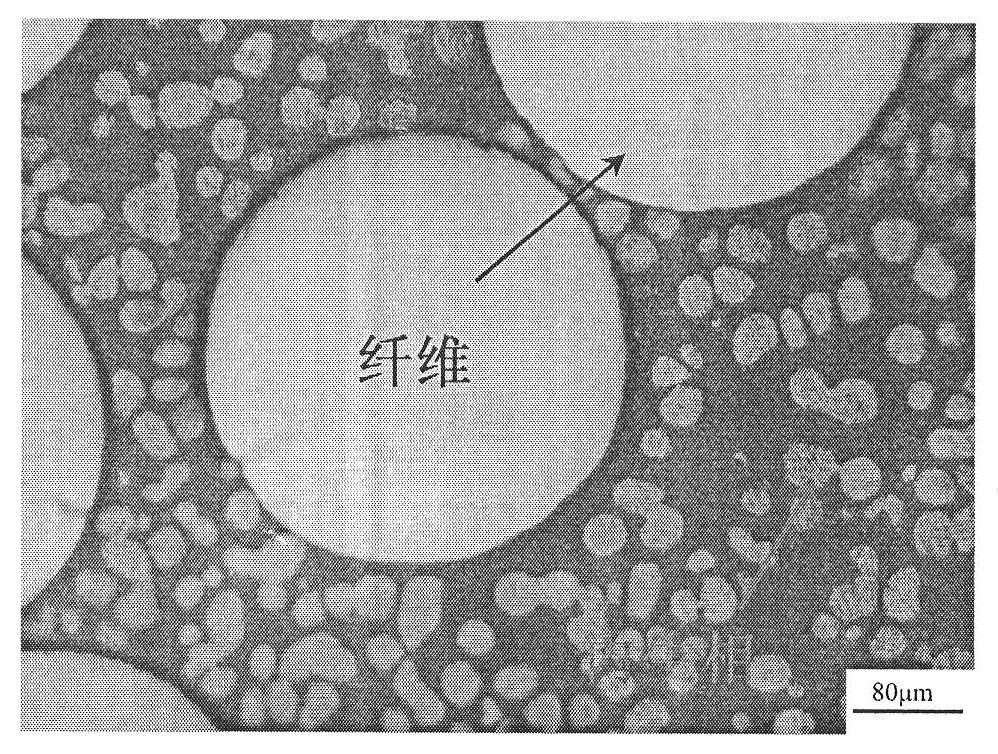

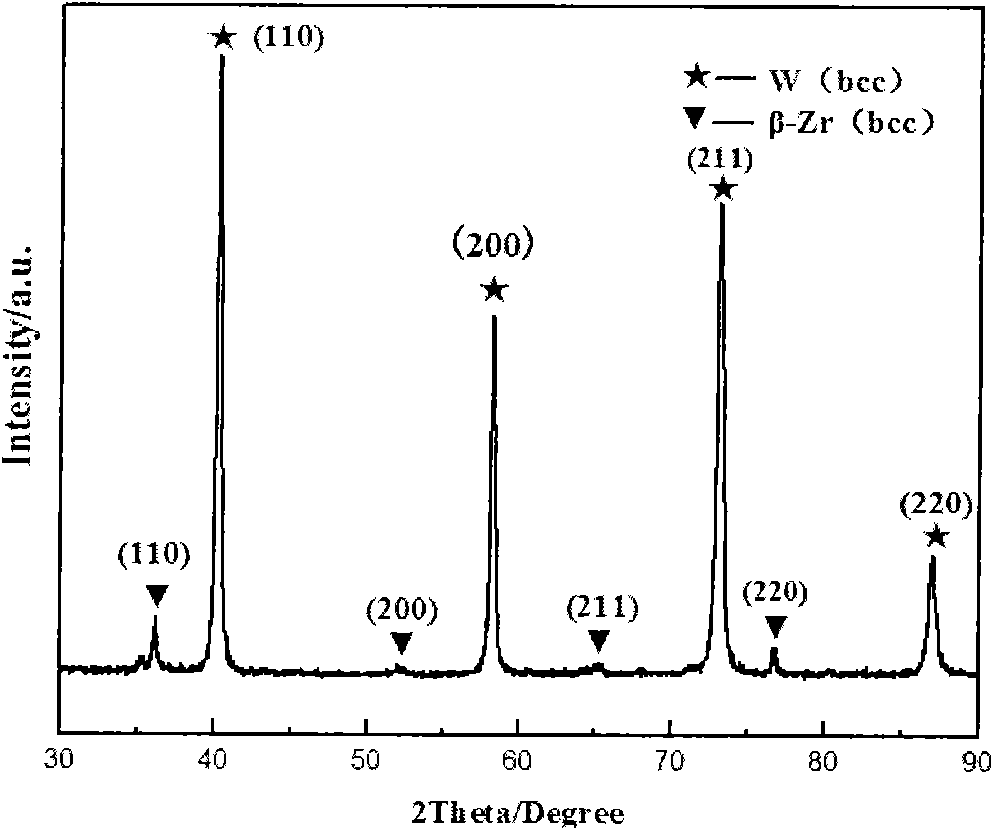

[0060] The performance test is the same as step 4 of Example 1. The endogenous reinforcing phase in the composite material is spherical β-Zr with a size of 10-80 μm. The yield strength of the prepared dual-phase composite material is 1650MPa, the fracture strength is 2170MPa, and the total fracture strain is 28%; Compared with the amorphous composite material with the same matrix composition and only containing endogenous spherulite reinforcement phase, the yield strength can be increased by 65%, the fracture strength can be increased by 14.8%, and the room temperature compression plasticity can be increased by 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com