Dual composite high strength and toughness block amorphous alloy and preparation method thereof

An amorphous alloy, high-strength technology, applied in the field of amorphous composite materials and its preparation, can solve the problems of not being able to prepare double-composite amorphous composite materials, improve interface wetting conditions, simulate interface reactions, and reduce infiltration effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

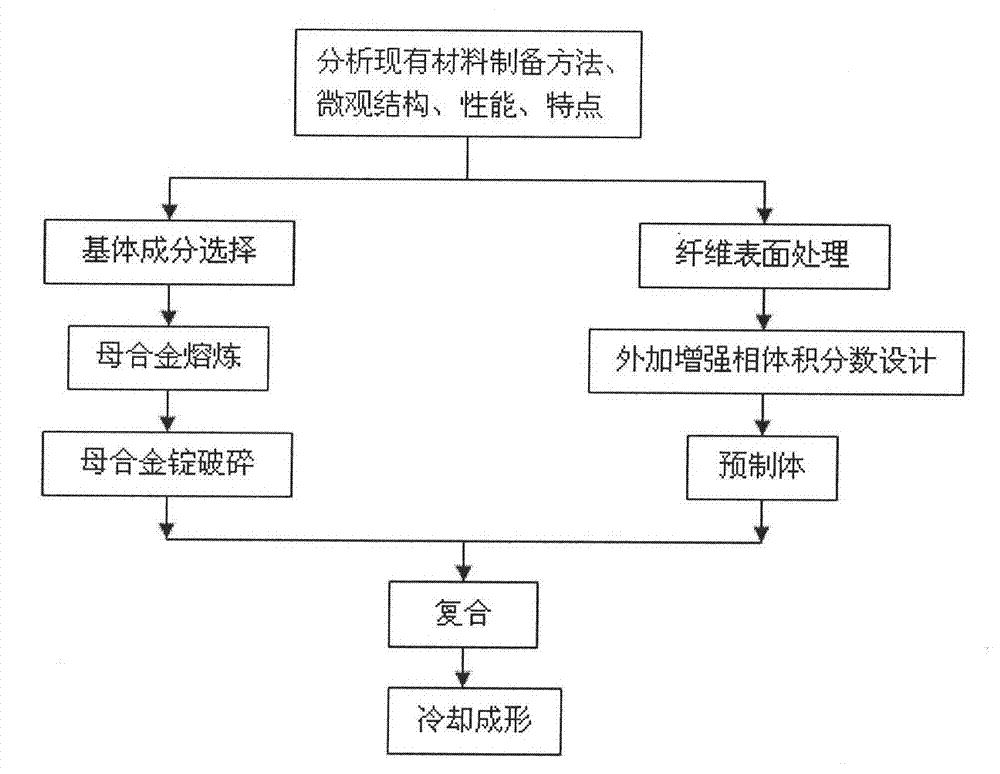

Method used

Image

Examples

Embodiment 1

[0046] (1) Selection of matrix alloy composition

[0047] The purity of each metal component selected for preparing the master alloy ingot is shown in Table 1, and the nominal composition of the alloy is Zr56.2Ti13.8Nb5.0Cu6.9Ni5.6Be12.5 (atomic percentage).

[0048] Table 1 prepares the purity (%) of the metal component selected from the master alloy ingot

[0049]

[0050] (2) Preparation of master alloy ingot

[0051] Under the conditions of Ti inhalation and high-purity argon protection, master alloy buckle ingots were melted in a non-consumable arc melting furnace.

[0052] The specific procedure for the preparation of master alloy buckle ingots is as follows:

[0053] After the surface of the metal raw material is mechanically polished to remove the oxide skin on the surface, the ingredients are proportioned according to the designed composition; the weighing is accurate to within 0.005g, and the prepared material is put into the melting furnace according to the wei...

Embodiment 2

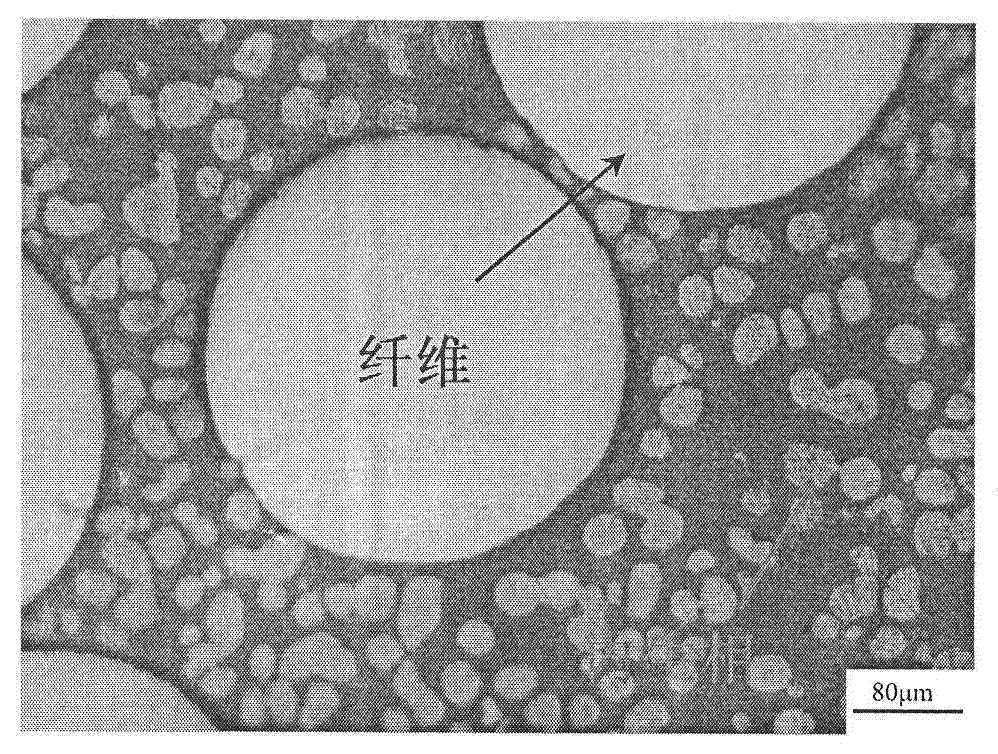

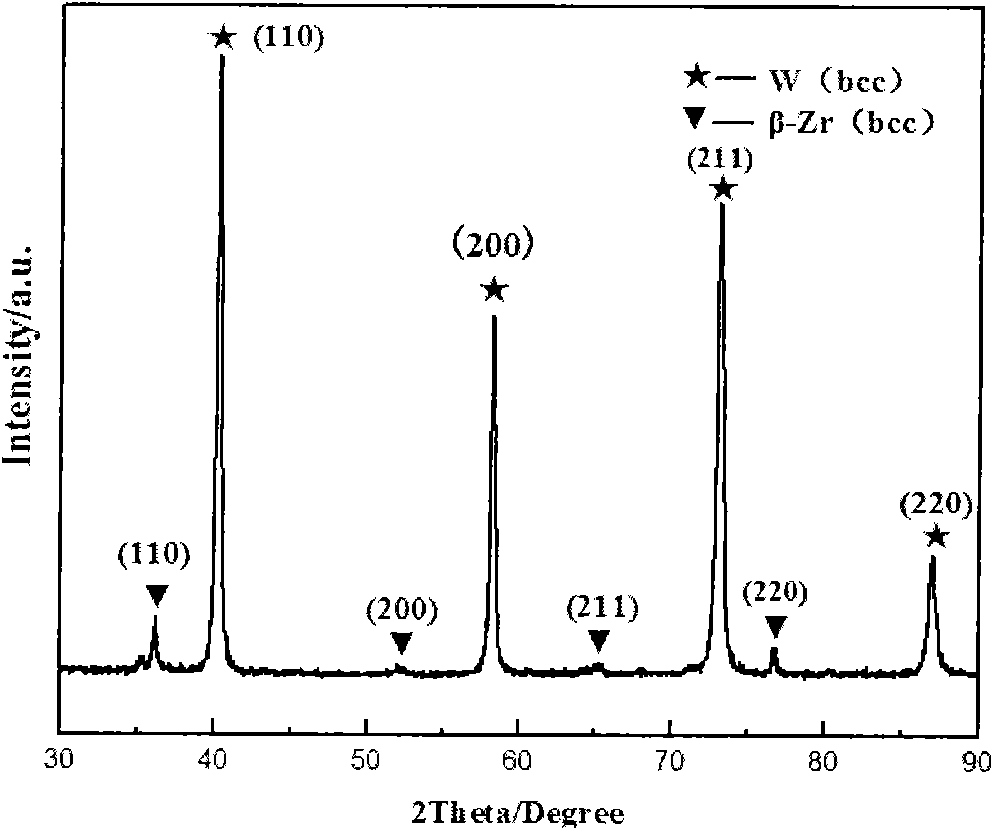

[0061] The composition of the matrix alloy is Zr60Ti14.67Nb5.33Cu5.56Ni4.44Be10 (atomic percentage), and the additional reinforcing phase is W fiber with a diameter of 0.28mm, and the volume fraction is 65%. Step 3 of Example 1 is the same, except that the holding temperature is 950°C, the holding time is 30 minutes, and the pressure of infiltration casting is 2MPa.

[0062] The performance test is the same as step 4 of Example 1. The endogenous reinforcing phase in the composite material is spherical β-Zr with a size of 10-80 μm. The yield strength of the prepared dual-phase composite material is 1650MPa, the fracture strength is 2170MPa, and the total fracture strain is 28%; Compared with the amorphous composite material with the same matrix composition and only containing endogenous spherulite reinforcement phase, the yield strength can be increased by 65%, the fracture strength can be increased by 14.8%, and the room temperature compression plasticity can be increased by 24...

Embodiment 3

[0064] (1) The composition of the matrix alloy is Zr52.2Ti13.8Nb5.0Cu6.9Ni7.6Be14.5 (atomic percentage). The smelting of the master alloy ingot is the same as Step 2 of Example 1.

[0065] (2) Adding reinforcing phase is the steel fiber of diameter 0.25mm, puts into the prefabricated body in the quartz tube by volume fraction 70%, adopts the method for embodiment 1 step 3, prepares the sample of amorphous composite material, and difference is heat preservation The temperature is 830°C, and the holding time is 10 minutes.

[0066] (3) performance detection is the same as embodiment 1 step 4

[0067] The endogenous reinforcing phase in the composite material is partly spherical β-Zr, with a size of 10-60 μm. The yield strength of the prepared dual-phase composite material reaches 1860MPa, and the total fracture strain is 10.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com