Device and method for separate preheating and one-step infiltration extrusion forming of magnesium-based composite

A composite material and extrusion forming technology, which is applied in the field of separate preheating and one-time impregnation extrusion forming of magnesium-based composite materials, and can solve the problem of metal-based composite materials. Poor material performance and other problems, to achieve the effect of slowing down the capillary phenomenon, ensuring the quality of the preparation, and reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Method Example 1: The matrix metal used in this example is AZ91D magnesium alloy, the liquidus is 596°C, and the preform 3 is made of T300 chopped carbon fiber with a volume fraction of 15-20%, which is prepared by a wet method, that is, carbon fiber, Pore agent, dispersant, adhesive and distilled water are mixed and stirred in a certain proportion, and the fibers are uniformly dispersed and poured into the mold to filter out water and press to form, and then dried at low temperature to obtain a prefabricated body. The preform is deposited pyrolytic carbon coating on the surface of carbon fiber by chemical vapor deposition method, and the deposition parameters are: N2 flux is 0.2m 3 / h, the CH4 feed rate is 20L / h, the deposition temperature is 1000°C, and the deposition time is 1.5 hours.

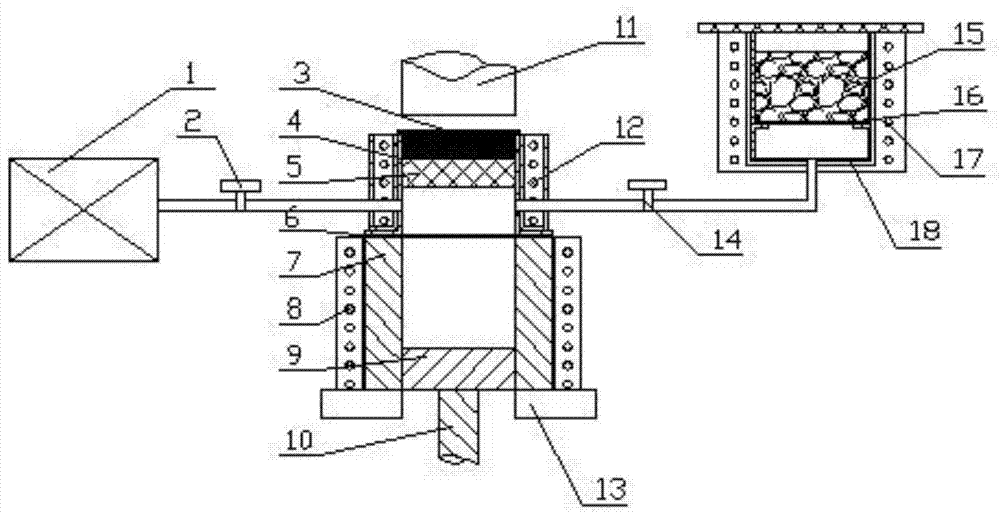

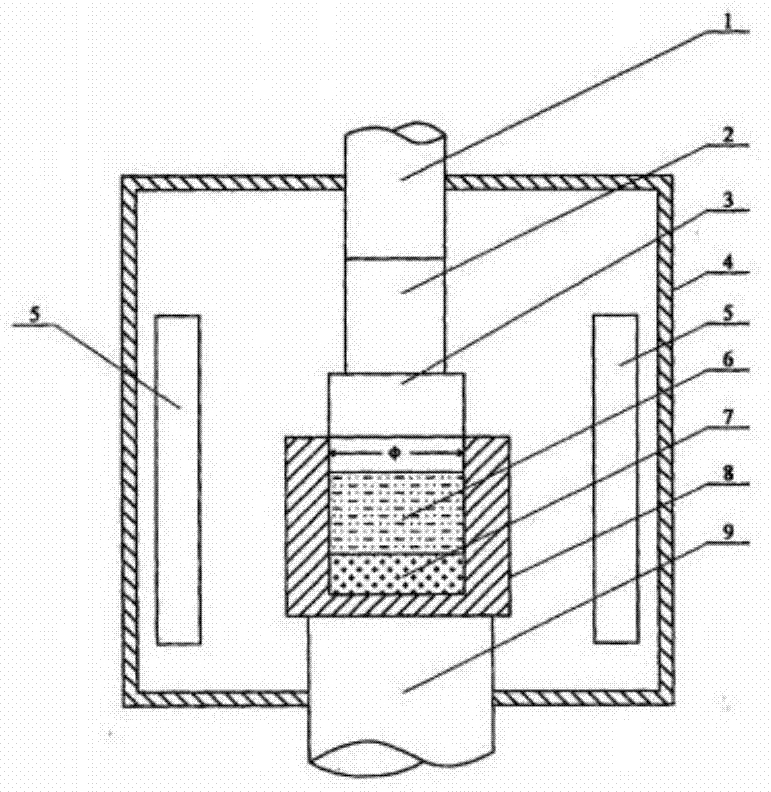

[0029] First, the lower sealing block 9 is pressed into the bottom of the extrusion cylinder 7, and the extrusion cylinder 7 is fixed on the base 13, the preform preheating chamber...

Embodiment 2

[0030] Method Example 2: The base metal used in this example is AZ91D magnesium alloy, and the liquidus is 596°C. The prefabricated body 5 adopts T700 carbon fiber non-weft cloth, and the non-weft cloth is cut into a disc equal to the inner diameter of the extrusion cylinder. It is made by cross-lamination of punctured carbon cloth in the prior art, the thickness is 15mm, and the volume fraction of the prefabricated body is 40-55%. The preform is deposited pyrolytic carbon coating on the surface of carbon fiber by chemical vapor deposition method, and the deposition parameters are: N2 flux is 0.2m 3 / h, the CH4 feed rate is 20L / h, the deposition temperature is 950°C, and the deposition time is 2 hours.

[0031] First, press the lower sealing block 9 into the bottom of the extrusion cylinder 7, fix the extrusion cylinder 7 on the base 13, fix the preform preheating chamber 4 on the extrusion cylinder 7, and keep the preheating chamber 4 in contact with the extrusion cylinder 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com