Method for recycling low-temperature waste heat from waste incineration fume

A technology of waste incineration and low-temperature waste heat, which is applied to the low-temperature waste heat recovery and utilization of flue gas in the chemical industry, iron and steel, and low-temperature waste heat recovery and utilization of waste incineration flue gas. Waste and other problems, to achieve good development prospects and promotion value, low operating costs, strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

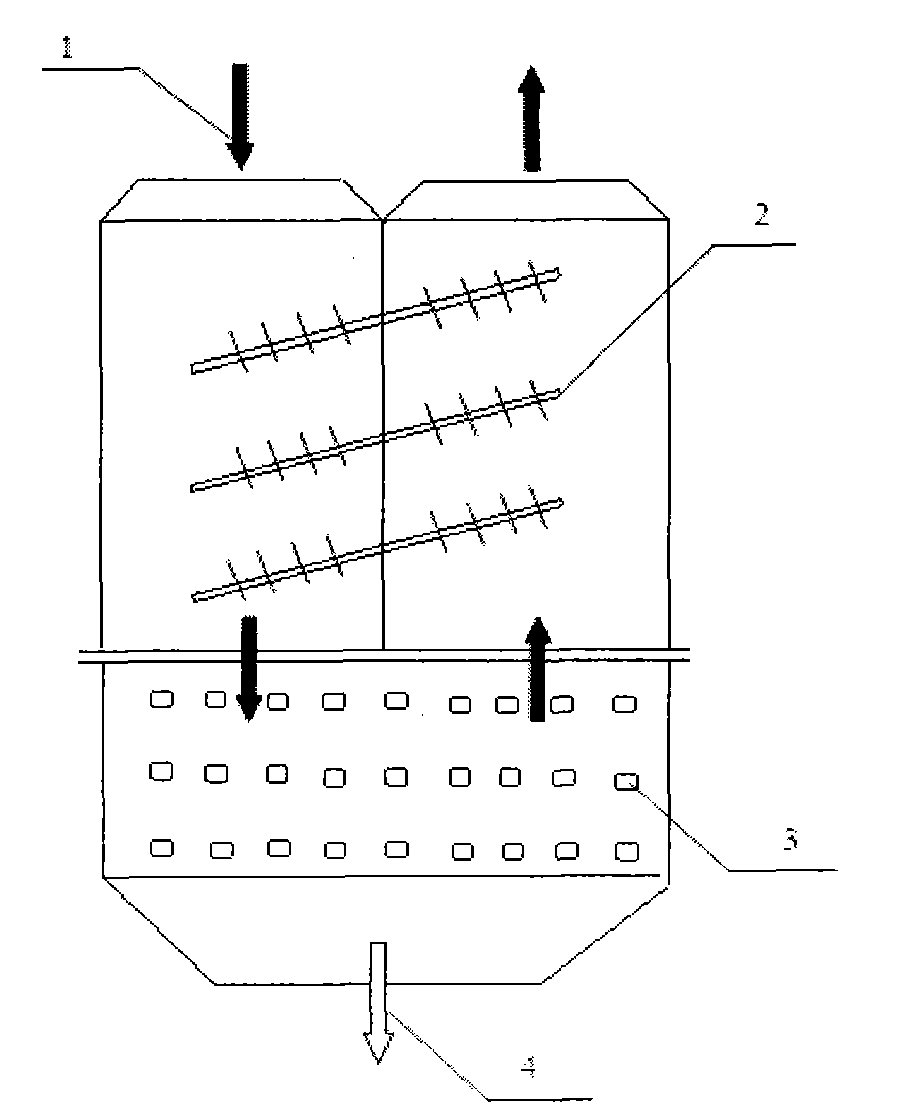

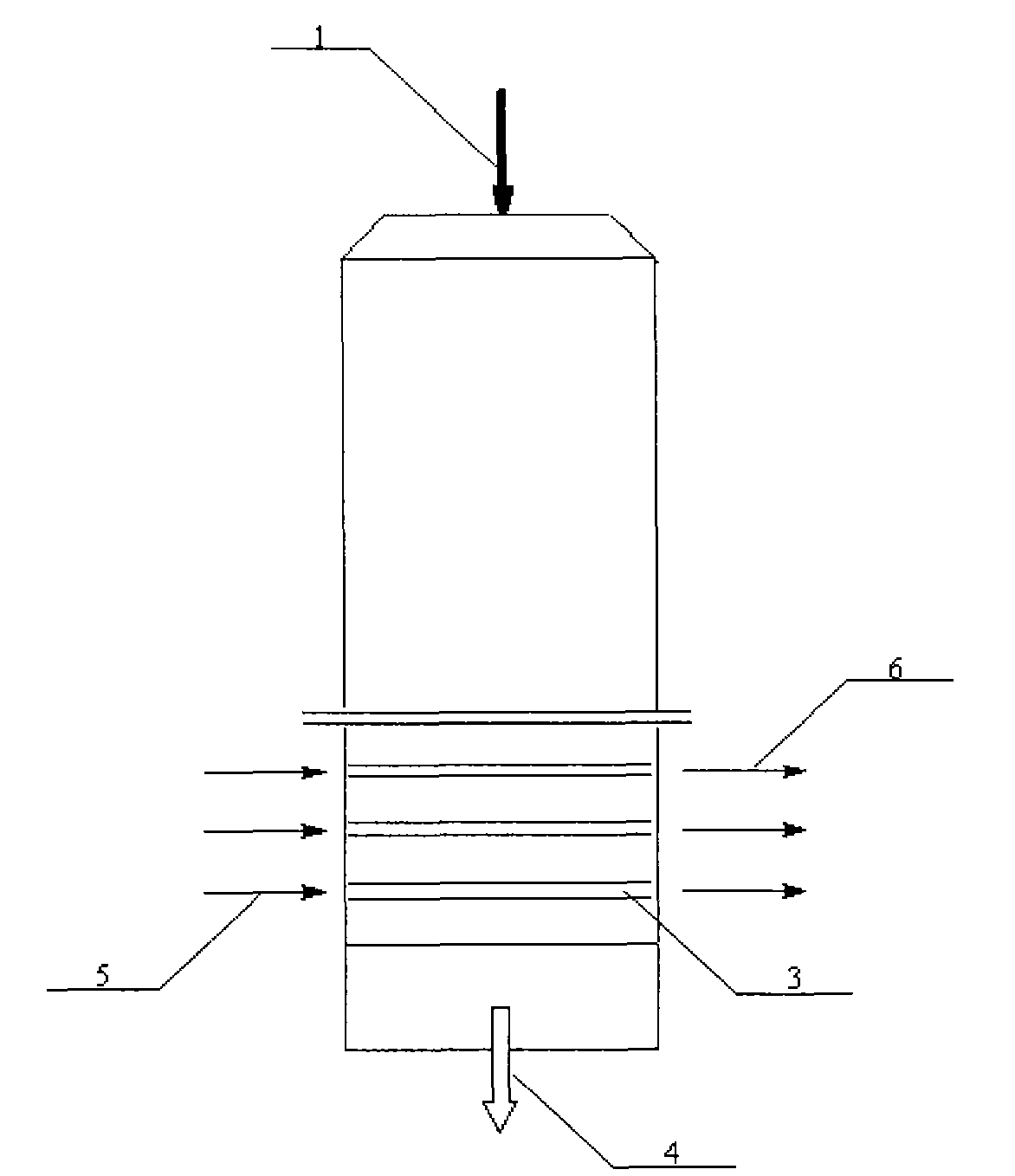

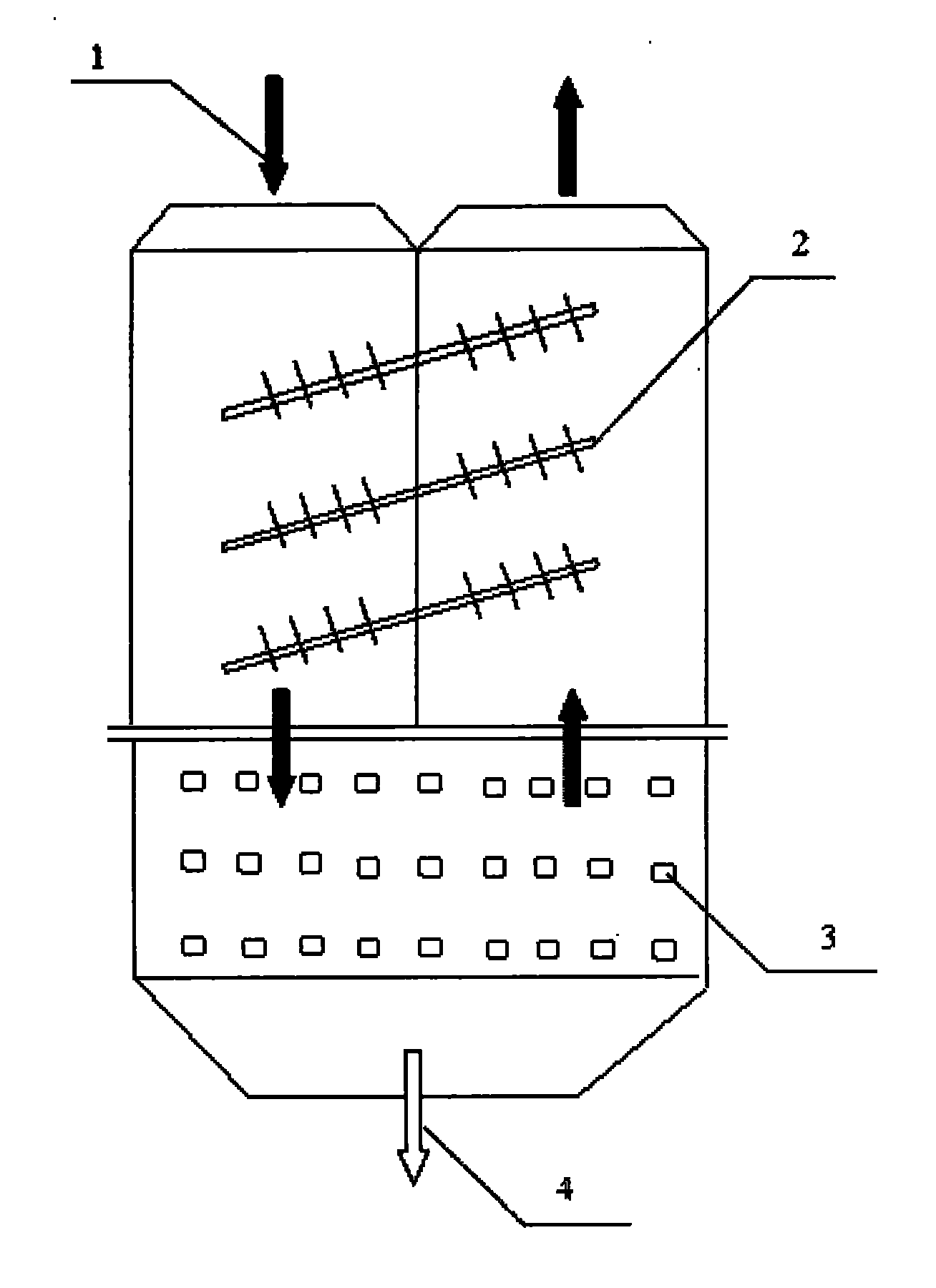

[0019] Low temperature flue gas conditions after dedusting: temperature 150°C, dust content about 2g / Nm 3 , the flow is about 92881Nm 3 / h, moisture content 31%.

[0020] The low-temperature flue gas 1 after dedusting flows through the whole system in a U shape. On the inlet side, the flue gas 1 is first cooled by the heat pipe 2 to recover part of the sensible heat, and the temperature is reduced to 120°C, and then enters the shell side of the tube condenser 3 to reduce the flue gas temperature below the dew point temperature, about 34°C. The normal temperature cooling water 5 in the tube side is heated accordingly to obtain hot water 6 . In this process, the total waste heat recovery can reach 13MW, and the flue gas condensate 4 is discharged from the bottom of the equipment. On the outlet side, the low-temperature flue gas recovers the sensible heat of the flue gas 1 on the inlet side through the heat pipe 2, and then the temperature rises again, reaching 80°C, and final...

Embodiment 2

[0023] Low temperature flue gas conditions after dedusting: temperature 160°C, dust content about 1.5g / Nm 3 , the flow is about 113456Nm 3 / h, moisture content 22%.

[0024] The low-temperature flue gas 1 after dedusting flows through the whole system in a U shape. On the inlet side, the flue gas 1 first cools down through the heat pipe 2 and recovers part of the sensible heat, the temperature drops to 135°C, and then enters the shell side of the tube condenser 3 to reduce the flue gas temperature below the dew point temperature, about 50°C. The normal temperature cooling water 5 in the tube side is heated accordingly to obtain hot water 6 . In this process, the total waste heat recovery can reach 10MW, and the flue gas condensate 4 is discharged from the bottom of the equipment. On the outlet side, the low-temperature flue gas recovers the sensible heat of the flue gas 1 on the inlet side through the heat pipe 2, and then the temperature rises again, reaching 90°C, and fin...

Embodiment 3

[0027] Low temperature flue gas conditions after dedusting: temperature 180°C, dust content about 1.8g / Nm 3 , the flow is about 10762Nm 3 / h, moisture content 25%.

[0028] The low-temperature flue gas 1 after dedusting flows through the whole system in a U shape. On the inlet side, the flue gas 1 first cools down through the heat pipe and recovers part of the sensible heat, the temperature drops to 130°C, and then enters the shell side of the tube condenser 3 to lower the flue gas temperature below the dew point temperature, about 59°C. The normal temperature cooling water 5 in the tube side is heated accordingly to obtain hot water 6 . In this process, the total waste heat recovery can reach 8MW, and the flue gas condensate 4 is discharged from the bottom of the equipment. On the outlet side, the low-temperature flue gas recovers the sensible heat of the flue gas 1 on the inlet side through the heat pipe 2, and then the temperature rises again, reaching 85°C, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com