Carbon nano-tube manufacturing method and carbon nano-tube manufacturing apparatus

A carbon nanotube and a manufacturing method technology, applied in the field of carbon nanotube manufacturing devices, can solve the problems of high carbon nanotubes, unusable, difficult to control the height of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

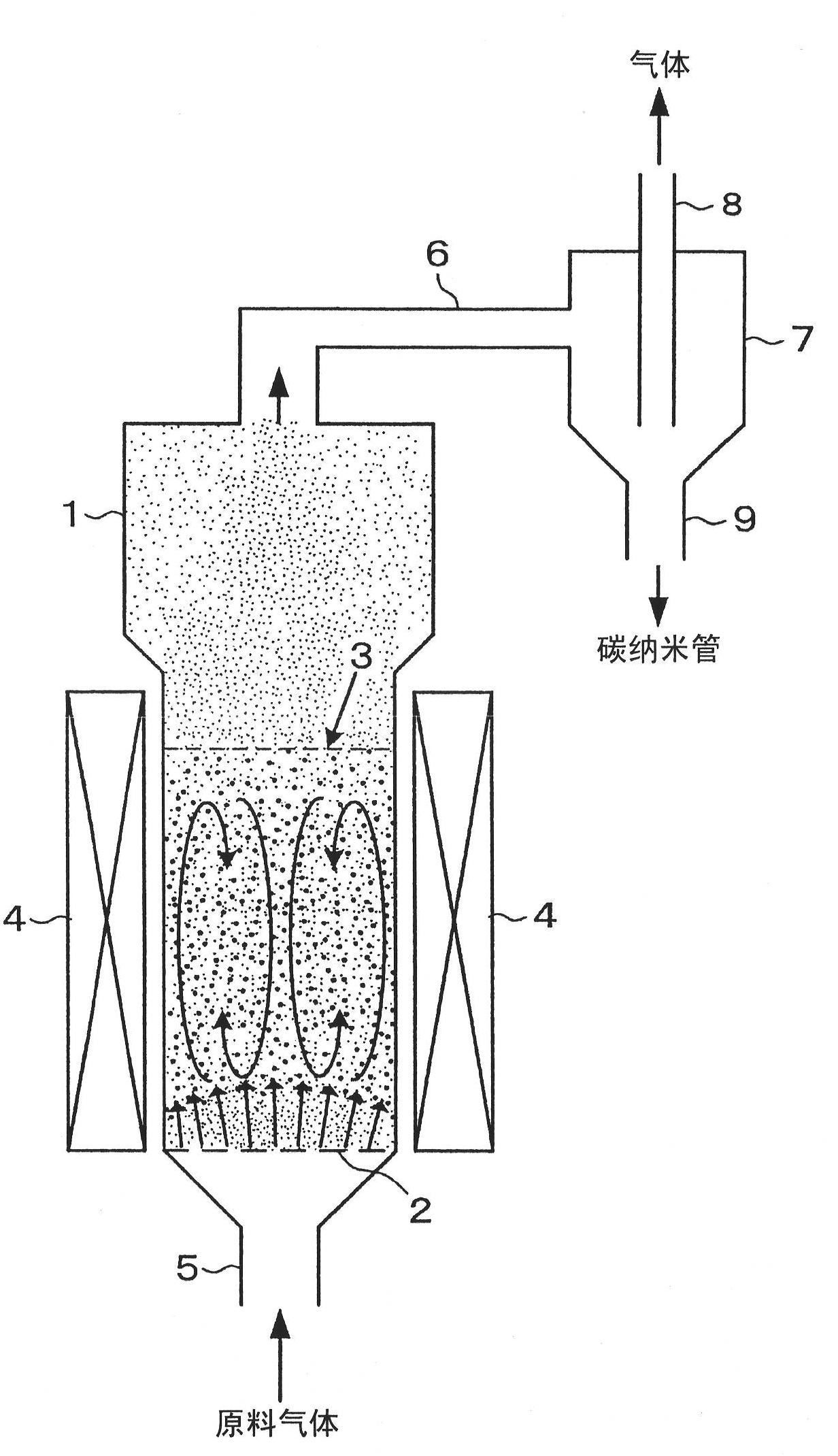

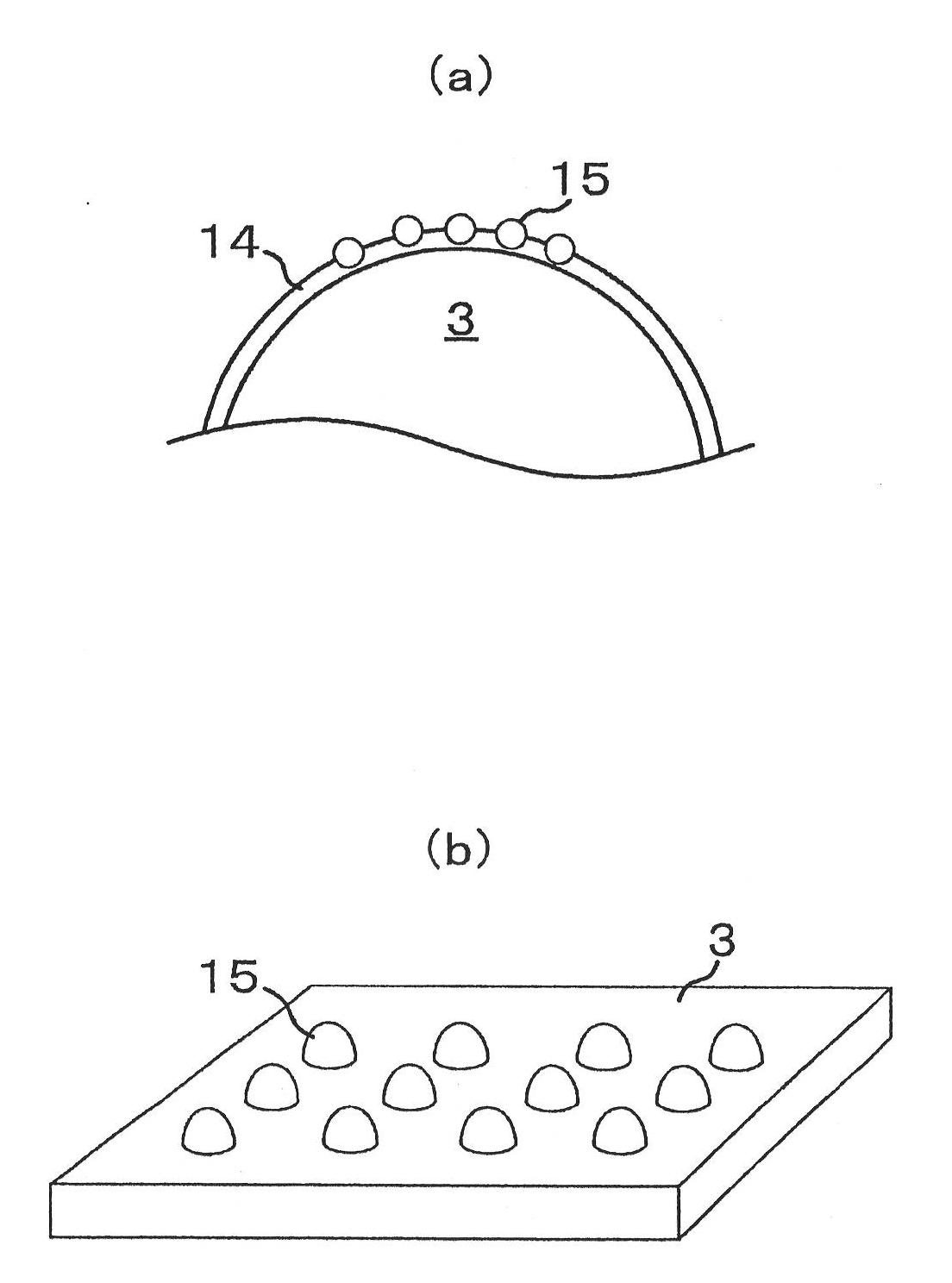

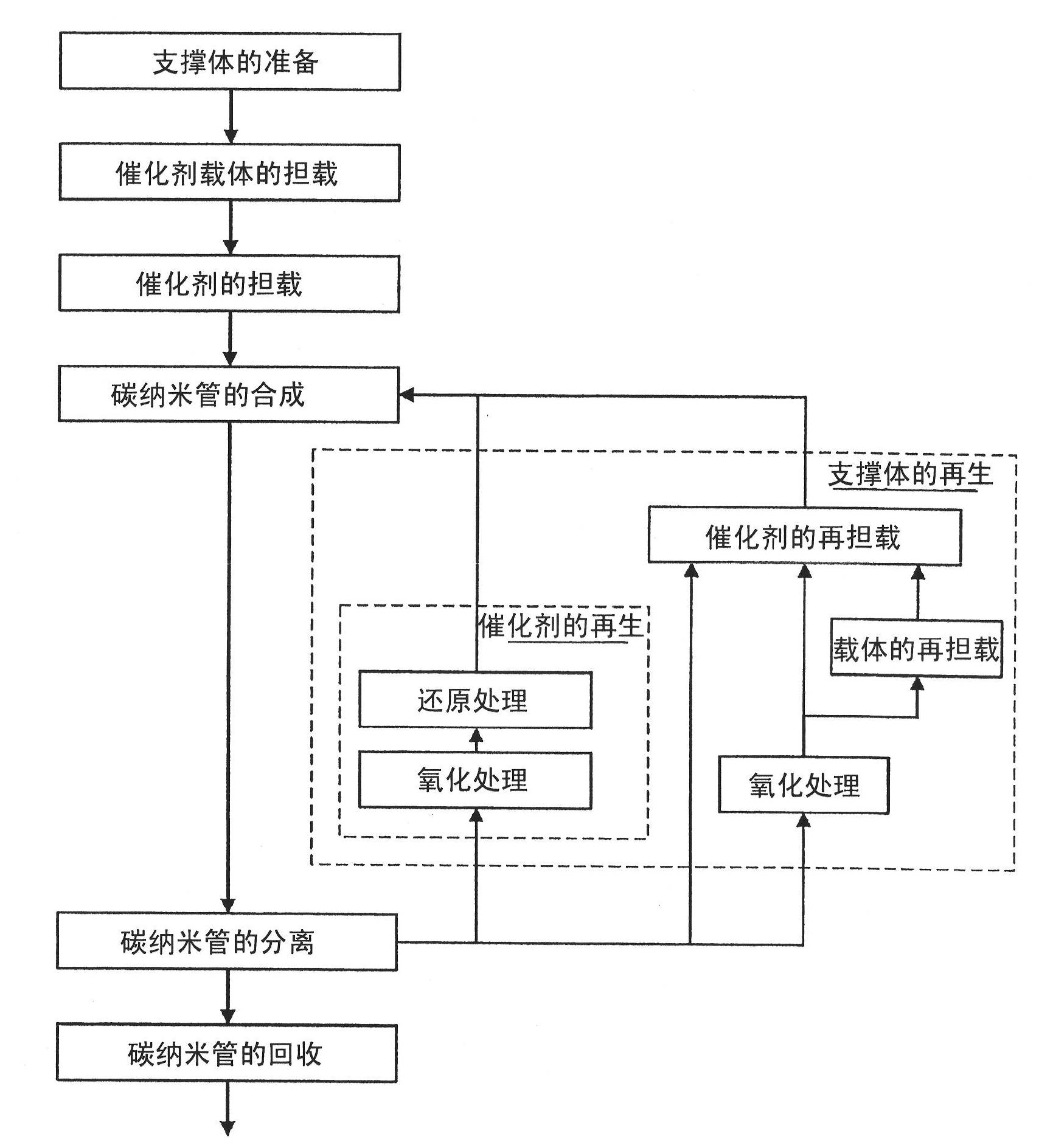

[0164] Example 1 of the present invention will be described. Here, as a support, alumina beads are used, on which Al 2 o 3 . Al 2 o 3 The carrier was sputtered into a film on alumina beads. The alumina beads had a diameter of 0.5 mm. Al 2 o 3 The thickness of the carrier (carrier layer) was 20 nm. Moreover, in Al 2 o 3 Fe is supported on the carrier as a catalyst. This loading is carried out by sputtering. Loaded on Al 2 o 3 The thickness of Fe on the support was 1 nm. Put this support in the reactor, while supplying 60Torr C to the reactor 2 h 4 / 200TorrH 2 / 100ppmvH 2 Carbon nanotubes are synthesized in a fluidized bed state while using atmospheric pressure gas of O / Ar balance.

[0165] The reactor is Figure 5 The shown quartz glass is a vertical CVD reactor that can be used both as a fixed bed and as a fluid bed. The temperature of the reaction part in the reactor was 800°C. The supply of normal-pressure gas was performed for 10 minutes, and the synth...

Embodiment 2

[0174] Next, Embodiment 2 of the present invention will be described. In Example 2, the catalyst was supported by circulating the carrier raw material vapor and the catalyst raw material vapor over the alumina beads in a high temperature state. Thereafter, carbon source steam was circulated over the catalyst-loaded high-temperature alumina beads to synthesize carbon nanotubes. Here, alumina beads were used as the support. As the alumina beads, those having a diameter of 0.5 mm were used. In this example 2, in Figure 4 Alumina beads were installed in the shown horizontal CVD apparatus, and the following processes were performed.

[0175] First, 0.2 to 0.5 mL of tetraethoxyorthosilicate (TEOS) was supplied under normal pressure with the entire apparatus heated to about 700°C. The TEOS supplied into the reactor evaporates and reacts on the surface of the alumina beads to form SiO 2 carrier layer. Next, set the device as a whole to about 400°C, and use SiO 2 Coated alumina...

Embodiment 3

[0178] Next, Embodiment 3 of the present invention will be described. In Example 3, the synthesis of carbon nanotubes was repeated. Here, as the support, alumina beads with a diameter of 0.5 mm were used. In this embodiment 3, in Figure 4 Alumina beads were installed in the horizontal CVD apparatus shown, and the following treatments were performed. First, SiO is formed on the surface of the alumina beads 2 carrier layer. Specifically, after heating the entire reaction apparatus to about 700° C., 0.2 to 0.5 mL of TEOS was supplied onto the alumina beads under normal pressure. The TEOS supplied into the reactor evaporates and reacts on the surface of the alumina beads to form SiO 2 carrier layer.

[0179] made of SiO 2 Coated alumina beads are loaded with Al at the same time 2 o 3 Support and Fe catalyst. This simultaneous loading is performed after heating the entire reaction apparatus to about 400°C. Simultaneously supply 3 mg of aluminum isopropoxide vapor as car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com