Method for preparing antibacterial nanofibre composite membrane by utilizing electrostatic spinning and application thereof

A nanofiber and electrospinning technology, which is applied in fiber processing, fiber chemical characteristics, filament/thread forming, etc., can solve the research on effective components of tea polyphenols and complexation reactions, prone to redox reactions, affecting applications, etc. problems, to achieve good toughness and biocompatibility, mild conditions, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

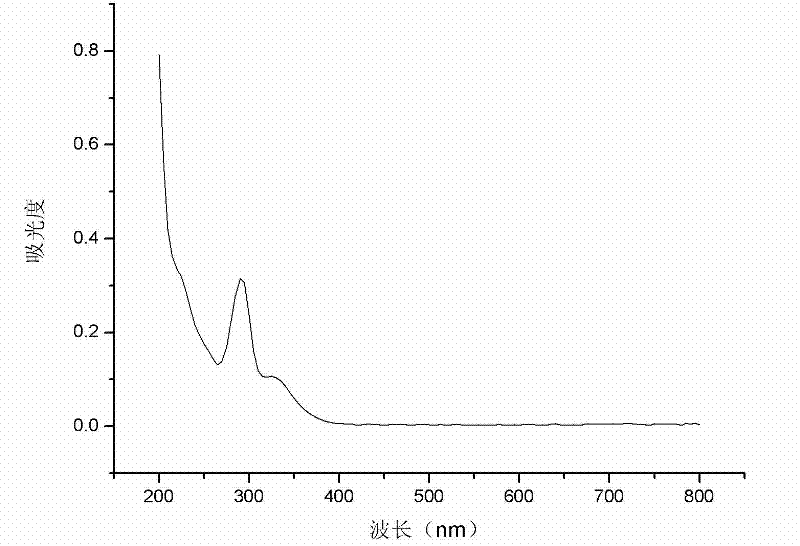

[0037] (1) Take 3ml of 5×10 -3 mol / l EGCG solution in the cuvette, then add 5μl 0.01 mol / l CuSO with a micropipette 4 Solution, with UV-Visible full-band spectrophotometer full-band detection, the results are as follows figure 1 shown.

[0038] (2) Weigh PVA (polyvinyl alcohol) and dissolve it in distilled water, heat to 95°C to fully dissolve, then add the solution in step (1), the final concentration of PVA is 8% (w / v, g / ml) , magnetically stirred at room temperature for 2 h for later use. Inhale the spinning solution into a 20ml syringe, install a needle with a diameter of 0.6mm, adjust the distance from the needle to the receiver to 6cm, adjust the voltage at 12kv, control the flow rate of the spinning solution at 2ml / h, spin for 2h, and vacuum dry at 80°C for 6h , to obtain EGCG_Cu (II) nanocomposite film.

Embodiment 2

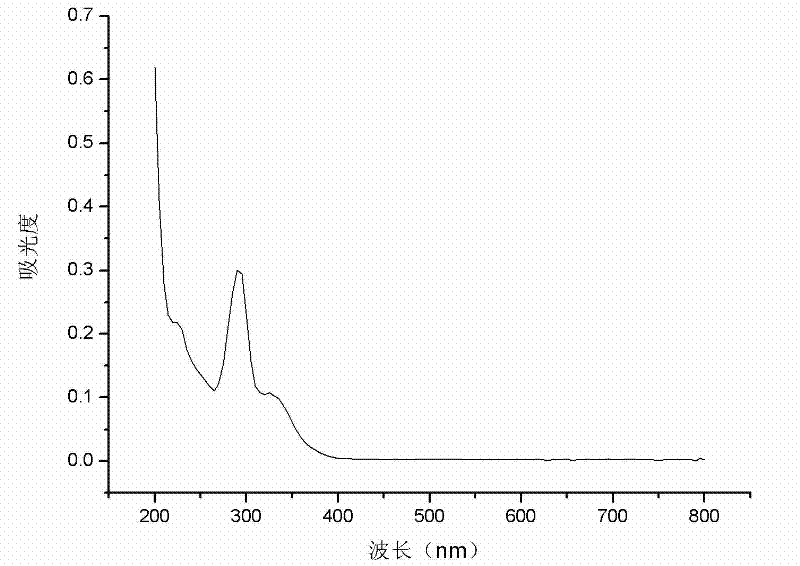

[0040] (1) Take 3ml 5×10 -3 mol / l EGCG solution in the cuvette, then add 10μl 0.01 mol / l CuSO with a micropipette 4 Solution, with UV-Visible full-band spectrophotometer full-band detection, the results are as follows figure 2 shown.

[0041] (2) Weigh PVA (polyvinyl alcohol) and dissolve it in distilled water, heat to 95°C to fully dissolve, then add the solution in step (1), the final concentration of PVA is 8% (w / v, g / ml) , magnetically stirred at room temperature for 2 h for later use. Inhale the spinning solution into a 20ml syringe, install a needle with a diameter of 0.6mm, adjust the distance from the needle to the receiver to 6cm, adjust the voltage at 12kv, control the flow rate of the spinning solution at 2ml / h, spin for 2h, and vacuum dry at 80°C for 6h , to obtain EGCG_Cu (II) nanocomposite film.

Embodiment 3

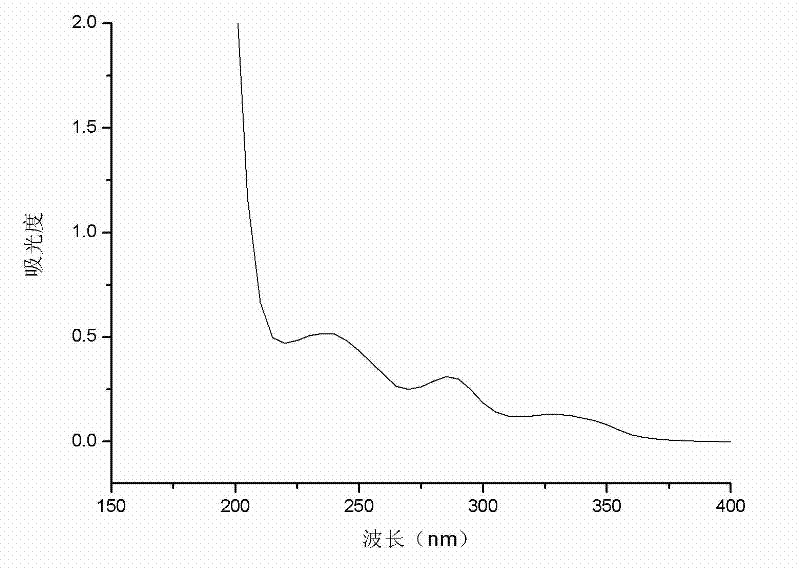

[0043] (1) Take 3ml 5×10 -3 mol / l EGCG solution in the cuvette, then add 15μl 0.01 mol / l CuSO with a micropipette 4 Solution, with UV-Visible full-band spectrophotometer full-band detection, the results are as follows image 3 shown.

[0044] (2 The details are as follows: Weigh PVA (polyvinyl alcohol) and dissolve it in distilled water, heat it to 95°C to fully dissolve it, then add the solution in step (1), the final concentration of PVA is 8% (w / v, g / ml), magnetically stirred at room temperature for 2 hours for later use. Inhale the spinning solution into a 20ml syringe, install a needle with a diameter of 0.6mm, adjust the distance from the needle to the receiver to 6cm, adjust the voltage at 12kv, and control the flow rate of the spinning solution at 2ml / h. Spinning for 2 hours, vacuum drying at 80°C for 6 hours to obtain EGCG_Cu(II) nanocomposite membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com