Multi-stage depressed collector material and preparation and surface treatment method thereof

A technology for surface treatment and collector, which is applied in the field of satellite traveling wave tube multi-stage step-down collector material and its preparation and surface treatment, which can solve the problems of low strength and difficult to guarantee the insulation performance of collector.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] 1. Using W and Cu as raw materials, the average particle size of W and Cu powder after bleaching treatment is 5-8 μm, and the volume ratio of W and Cu powder is formulated according to 45:55;

[0075] 2. Isostatic pressing after dry ball milling, molding pressure 200MPa;

[0076] 3. Sintering temperature: 1150±50°C, heat preservation for 4 hours to obtain a sintered body with a density greater than 95%;

[0077] 4. After ultrasonically cleaning and drying the sintered body with acetone, soak it in the chromic acid solution for 20-50 seconds and take it out;

[0078] 5. Deacidification and dehydration treatment: Soak the sample treated with chromic acid solution in distilled water and boil for 5-8 minutes. Repeat wash 3 times. Then dehydrate with acetone and dry.

[0079] 6. Hydrogen treatment: 950±20°C, duration 15-40 minutes, hydrogen dew point not higher than -35°C.

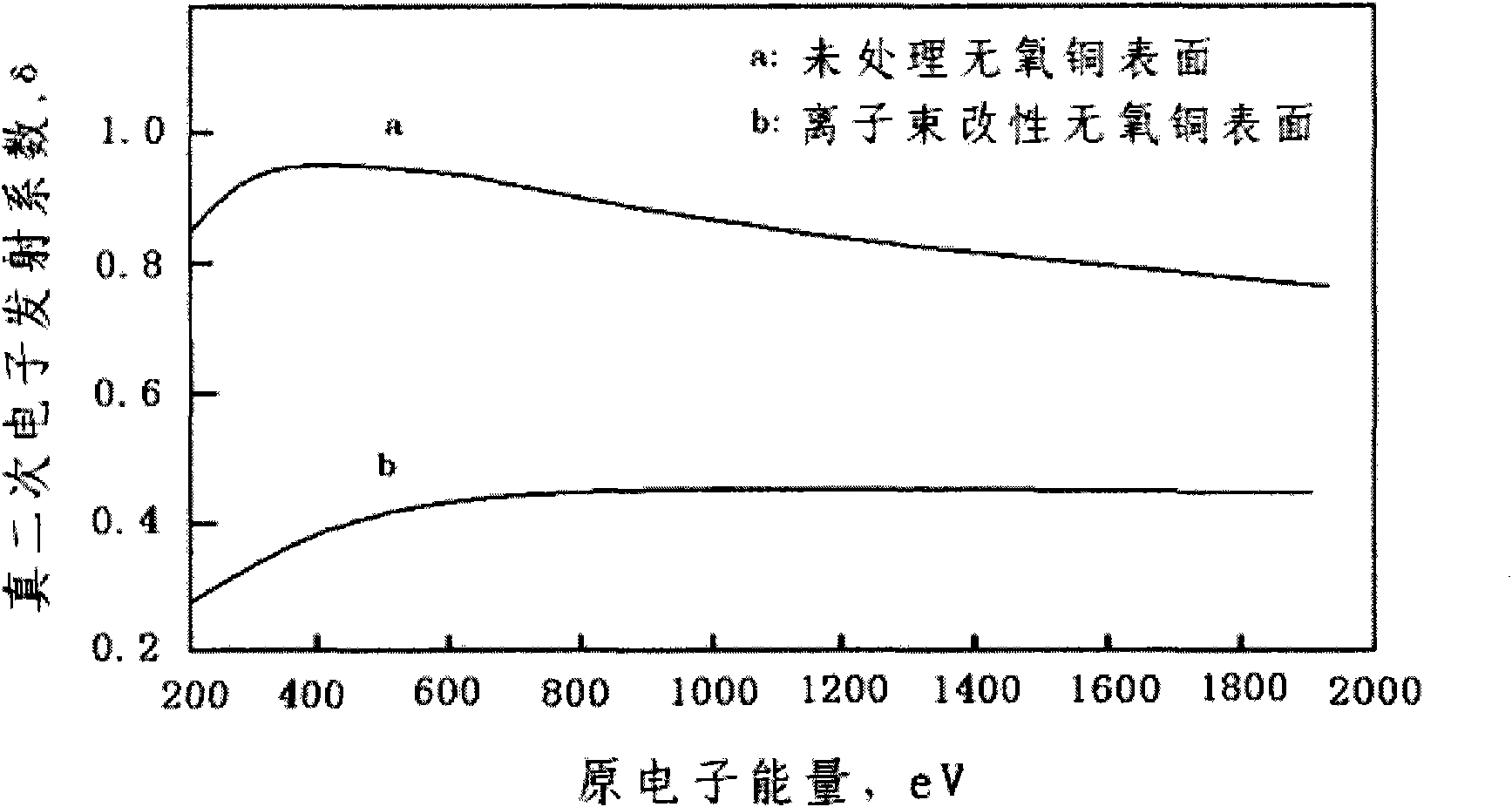

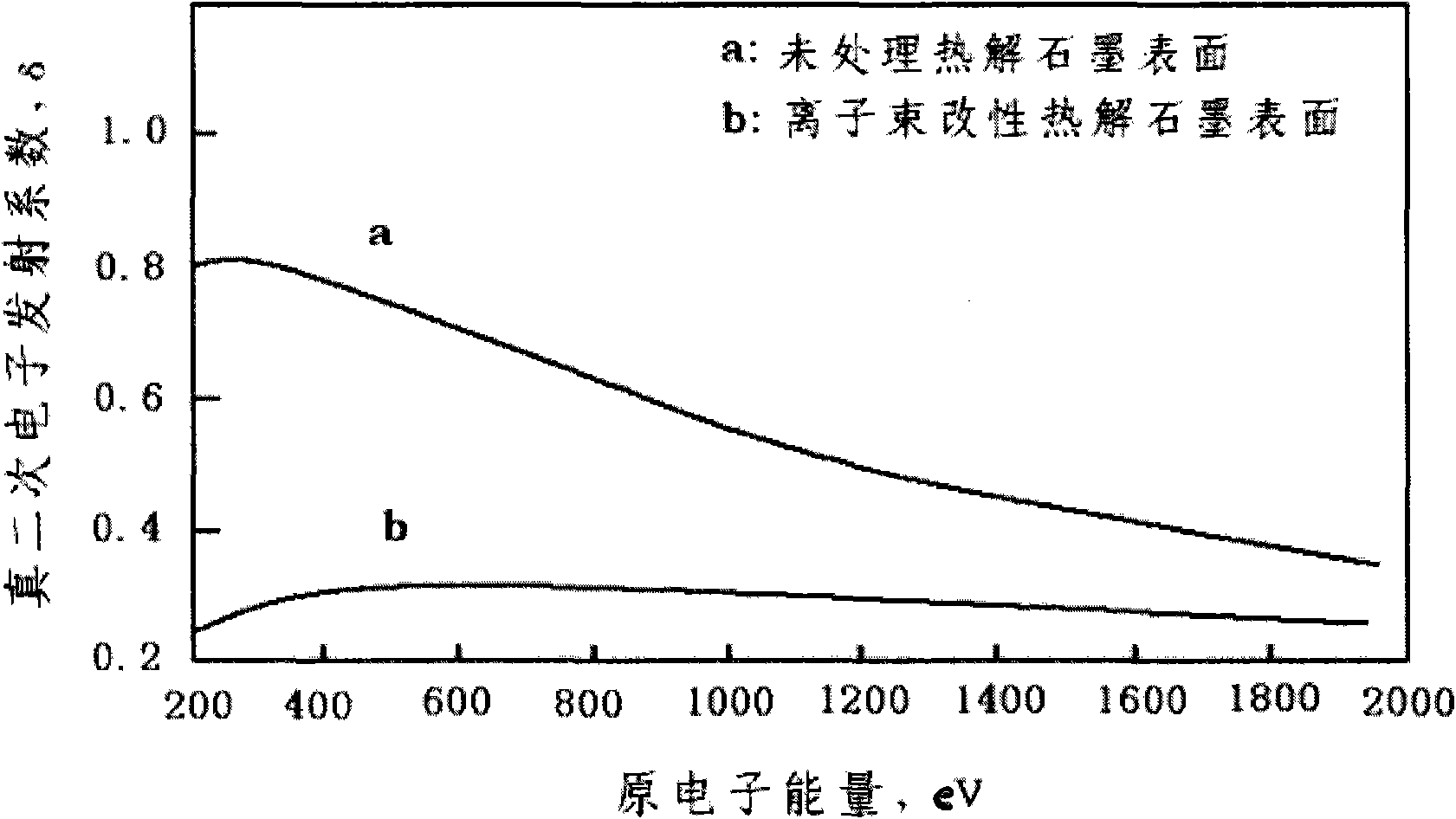

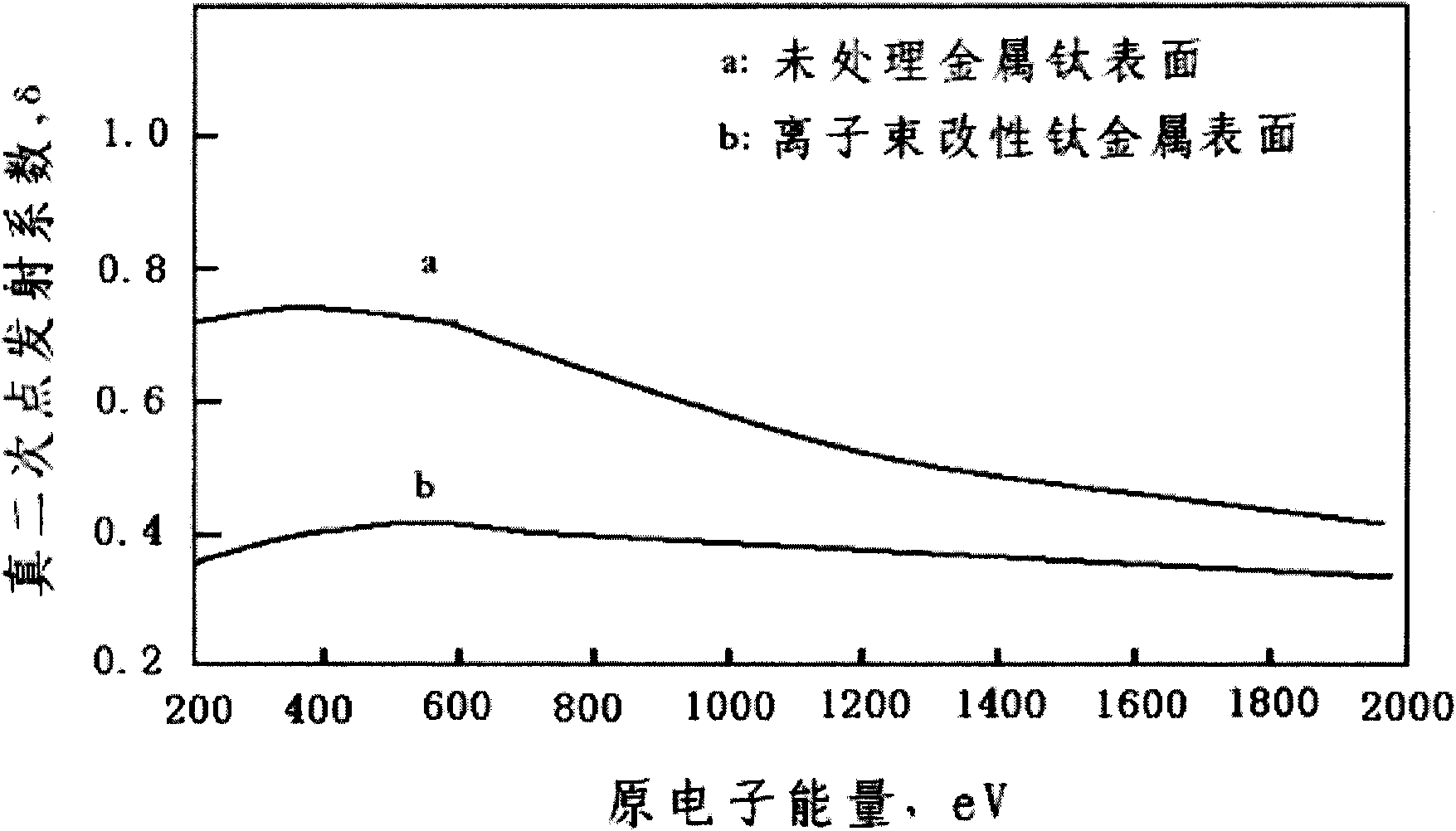

[0080] After processing by the process of the method of the present invention, the surface morpho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com