Method for preparing nano calcium carbonate for high-temperature resistant polymers

A high-temperature-resistant polymer and nano-calcium carbonate technology, which is applied in the treatment of dyed organic silicon compounds, dyed low-molecular organic compounds, and fibrous fillers, can solve the problem of poor heat resistance and does not involve heat-resistant nano-carbonic acid modifiers. Problems such as the influence of calcium application material properties, to achieve the effect of improving product uniformity, facilitating continuous production operation, and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

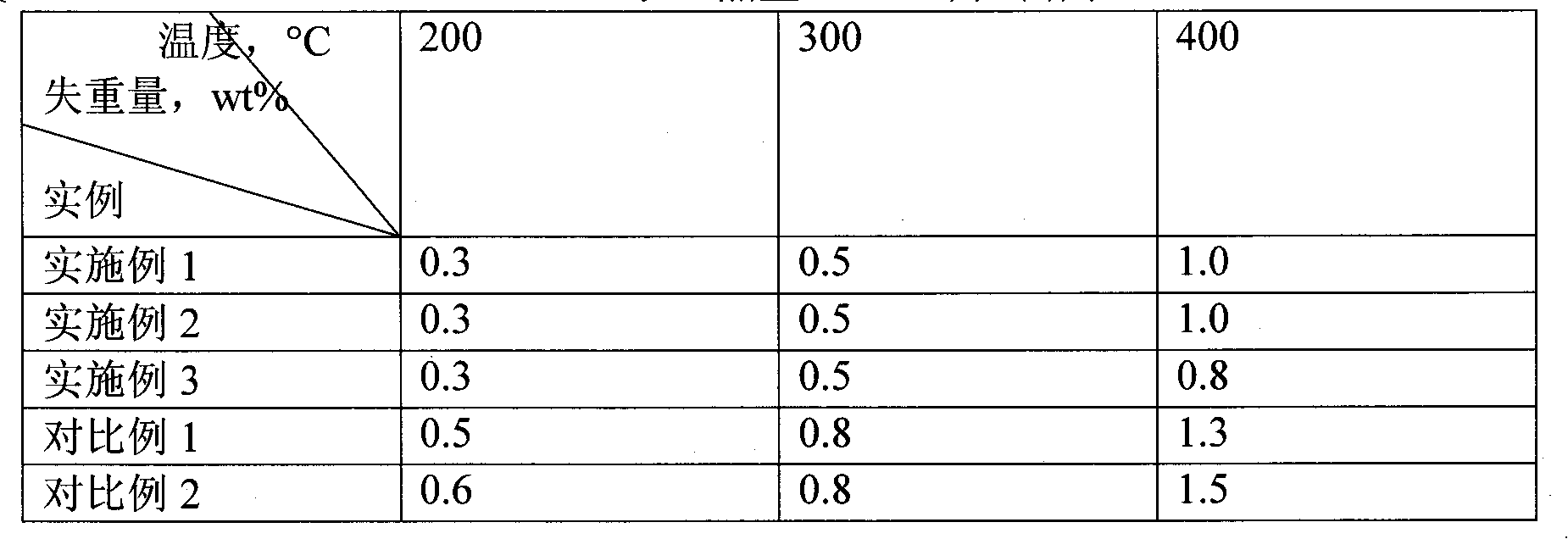

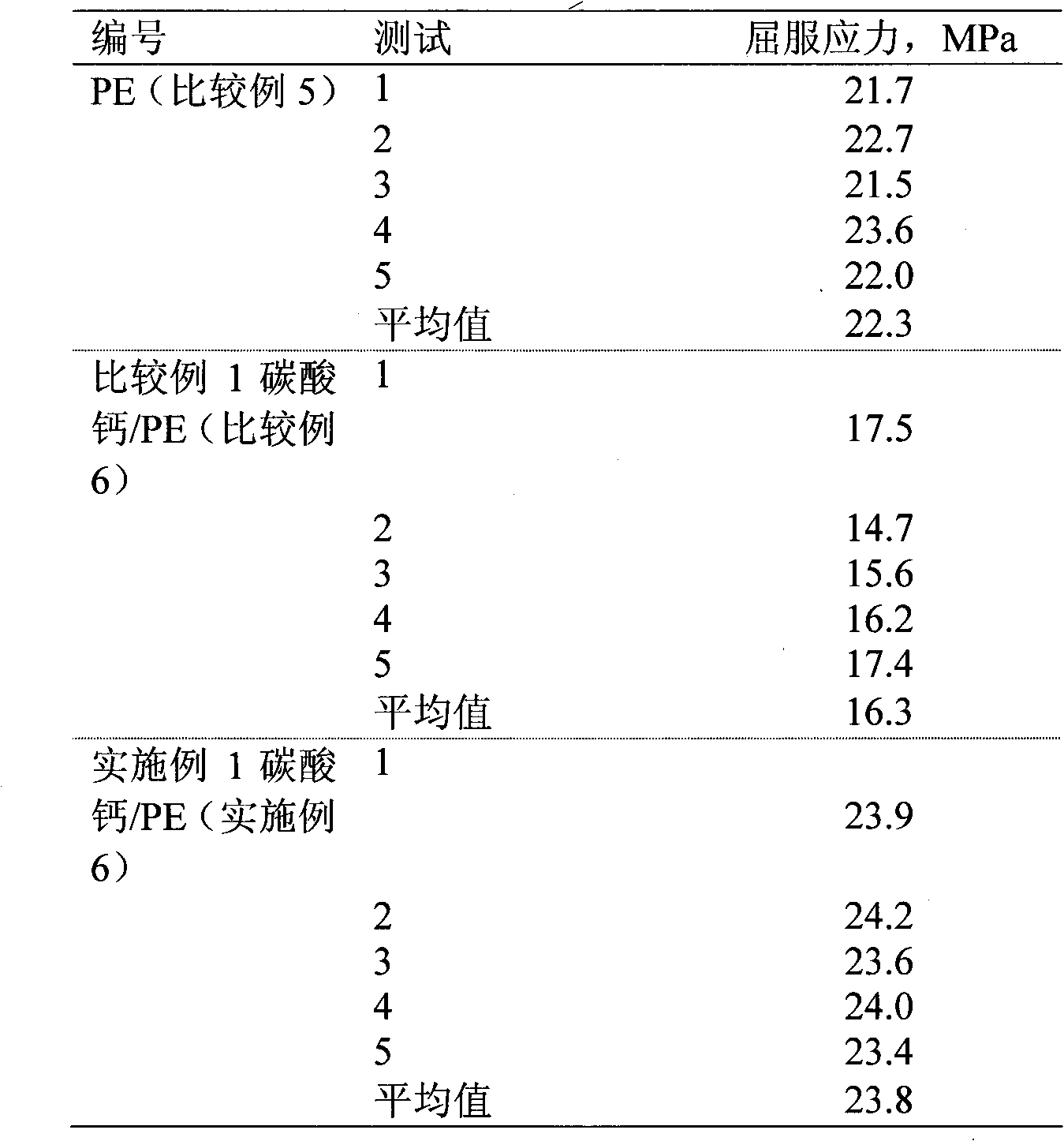

Embodiment 1

[0018] After the limestone is cleaned, it is calcined at 1000°C, and it is digested with water at 80°C to obtain a Ca(OH)2 slurry, which is transferred to a membrane dispersion carbonization reactor, and 0.5% (relative to Ca(OH)2) of sucrose is added. Feed 30% (v) of CO2 at 17 ° C for carbonization, when the pH drops to 6.8, continue to ventilate for 10 minutes to obtain 8% nanometer CaCO3 protoplasm. Heat the raw slurry, raise the temperature to 80° C. and stir for 5 minutes, add 1.5% (relative to CaCO3) stearic acid, and stir for 1 hour. Weigh 2% (relative to calcium carbonate) of a titanate modifier containing a benzene ring, add a small amount of water, emulsify at room temperature for 15 minutes, heat to 80°C, add stearic acid modified calcium carbonate slurry In the material, continue stirring for 3 hours, place overnight, dry and pulverize after filtering, and make the product of the present invention.

Embodiment 2

[0020] After the limestone is cleaned, it is calcined at 1000°C, and it is digested with water at 80°C to obtain a Ca(OH)2 slurry, which is transferred to a membrane dispersion carbonization reactor, and 0.5% (relative to Ca(OH)2) of sucrose is added. Feed 30% (v) of CO2 at 17 ° C for carbonization, when the pH drops to 6.8, continue to ventilate for 10 minutes to obtain 8% nanometer CaCO3 protoplasm. Heat the raw slurry, raise the temperature to 80° C. and stir for 5 minutes, add 1.5% (relative to CaCO3) stearic acid, and stir for 1 hour. Weigh 3% (relative to calcium carbonate) of a titanate modifier containing a benzene ring, add a small amount of water, emulsify at room temperature for 15 minutes, heat to 80°C, add stearic acid modified calcium carbonate slurry In the material, continue stirring for 3 hours, place overnight, dry and pulverize after filtering, and make the product of the present invention.

Embodiment 3

[0022] After the limestone is cleaned, it is calcined at 1000°C, and it is digested with water at 80°C to obtain a Ca(OH)2 slurry, which is transferred to a membrane dispersion carbonization reactor, and 0.5% (relative to Ca(OH)2) of sucrose is added. Feed 30% (v) of CO2 at 17 ° C for carbonization, when the pH drops to 6.8, continue to ventilate for 10 minutes to obtain 8% nanometer CaCO3 protoplasm. Heat the original slurry, raise the temperature to 80°C for emulsification for 5 minutes, add 1.5% (relative to CaCO3) stearic acid, emulsify for 1 hour, filter and then dry and pulverize. Add water to the pulverized sample to form an 8% slurry, heat to 80°C, emulsify for 5 minutes, weigh 2% (relative to calcium carbonate) of a titanate modifier containing a benzene ring, add a small amount of water, Emulsify at normal temperature for 15 minutes and heat to 80°C, add to stearic acid-modified calcium carbonate slurry, continue to emulsify for 3 hours, leave overnight, filter, dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com