Multilevel-structure hydrotalcite adsorbent and preparation method thereof

A technology of structural water and adsorbent, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problem of product form limiting the in-depth application of hydrotalcite, and achieve excellent adsorption performance, low cost, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step A: Dissolve sodium dodecylsulfonate (SDS) in 80 mL deionized water in a 100 mL polytetrafluoroethylene liner to prepare an aqueous solution with a molar concentration of SDS of 0.010 mol / L, and the water temperature is 60°C.

[0019] Step B: under rapid stirring, Mg(NO 3 ) 2 and urea (Urea) are dissolved in a solution, and then Al(NO 3 ) 3 , stir the mixture for 2-3 minutes, so that the Mg in the reaction mixture 2+ / Al 3+ The initial molar ratio of / SDS / Urea is: 2 / 1 / 1 / 10.

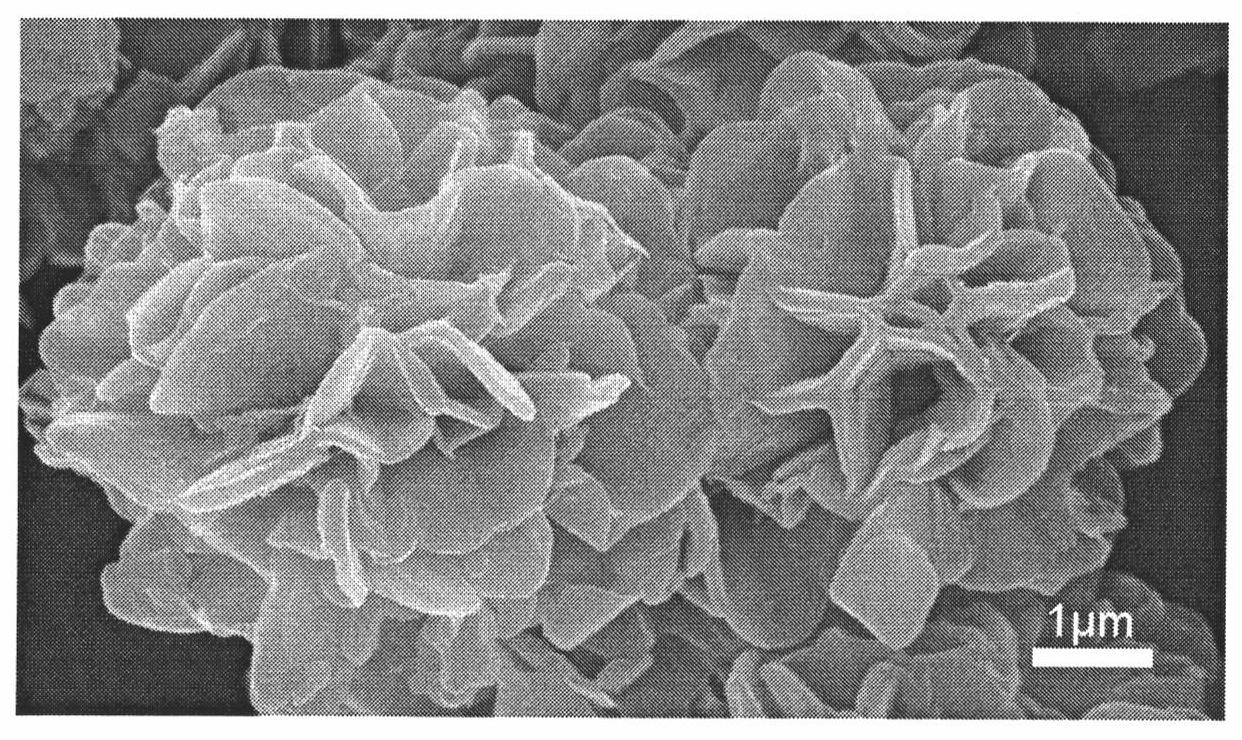

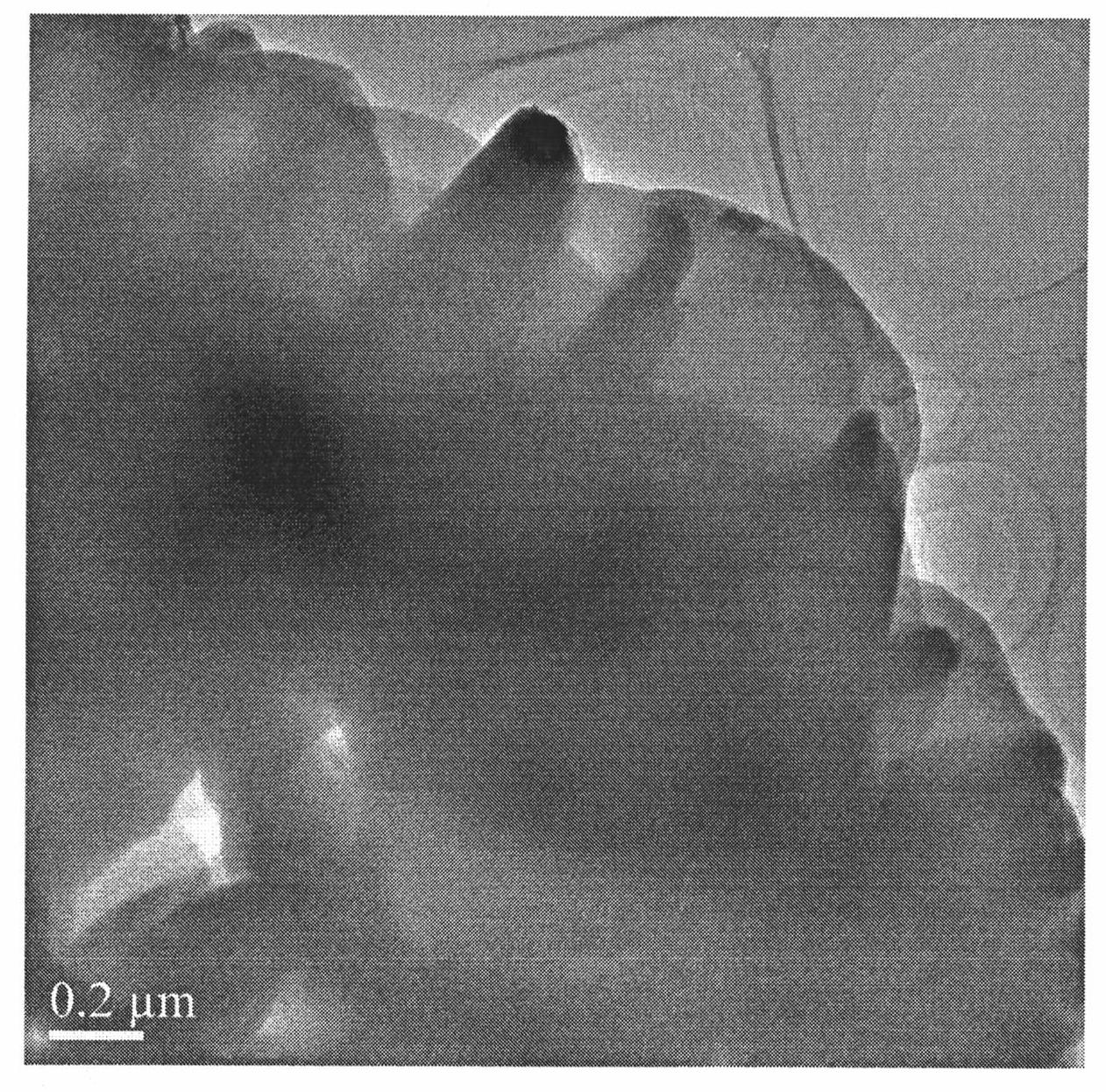

[0020] Step C: The reaction mixture obtained in b is placed in a pressure vessel, and statically crystallized at 150° C. for 24 hours. The resulting final product slurry was washed with deionized water and absolute ethanol, filtered and dried to give the product as a white solid powder.

[0021] Known by elemental analysis, the chemical composition of the product is [Mg 2+ 0.67 Al 3+ 0.33 (OH) 2 ] 0.33+ (DS - ) 0.33 0.57H 2 O, where, DS - For dodecylsulfonate anion. It can be s...

Embodiment 2

[0023] Step A: Dissolve sodium dodecylsulfonate (SDS) in 80 mL deionized water in a 100 mL polytetrafluoroethylene liner to prepare an aqueous solution with a molar concentration of SDS of 0.015 mol / L, and the water temperature is 60°C.

[0024] Step B: under rapid stirring, Mg(NO 3 ) 2 and urea (Urea) are dissolved in a solution, and then Al(NO 3 ) 3, stir the mixture for 2-3 minutes, so that the Mg in the reaction mixture 2+ / Al 3+ The initial molar ratio of / SDS / Urea is: 2 / / 1 / 1.5 / 10.

[0025] Step C: The reaction mixture obtained in b is placed in a pressure vessel, and statically crystallized at 150° C. for 24 hours. The resulting final product slurry was washed with deionized water and absolute ethanol, filtered and dried to give the product as a white solid powder.

[0026] Known by elemental analysis, the chemical composition of the product is [Mg 2+ 0.65 al 3+ 0.35 (OH) 2 ] 0.35+ (DS - ) 035 0.55H 2 O, where, DS - For dodecylsulfonate anion. It can be ...

Embodiment 3

[0028] Step A: Dissolve sodium dodecylsulfonate (SDS) in 80 mL deionized water in a 100 mL polytetrafluoroethylene liner to prepare an aqueous solution with a molar concentration of SDS of 0.0175 mol / L, and the water temperature is 60°C.

[0029] Step B: under rapid stirring, Mg(NO 3 ) 2 and urea (Urea) are dissolved in a solution, and then Al(NO 3 ) 3 , stir the mixture for 2-3 minutes, so that the Mg in the reaction mixture 2+ / Al 3+ The initial molar ratio of / SDS / Urea is: 2 / / 1 / 1.75 / 10.

[0030] Step C: The reaction mixture obtained in b is placed in a pressure vessel, and statically crystallized at 150° C. for 24 hours. The resulting final product slurry was washed with deionized water and absolute ethanol, filtered and dried to give the product as a white solid powder.

[0031] Known by elemental analysis, the chemical composition of the product is [Mg 2+ 0.64 al 3+ 0.36 (OH) 2 ] 0.36+ (DS - ) 0.36 0.53H 2 O, where, DS - For dodecylsulfonate anion. It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com