Molecular sieve catalyst for preparing propylene from methanol/dimethyl ether and preparation method thereof

A molecular sieve and catalyst technology, applied in the field of catalyst preparation, can solve the problems of acidic sewage environmental pollution, high cost, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

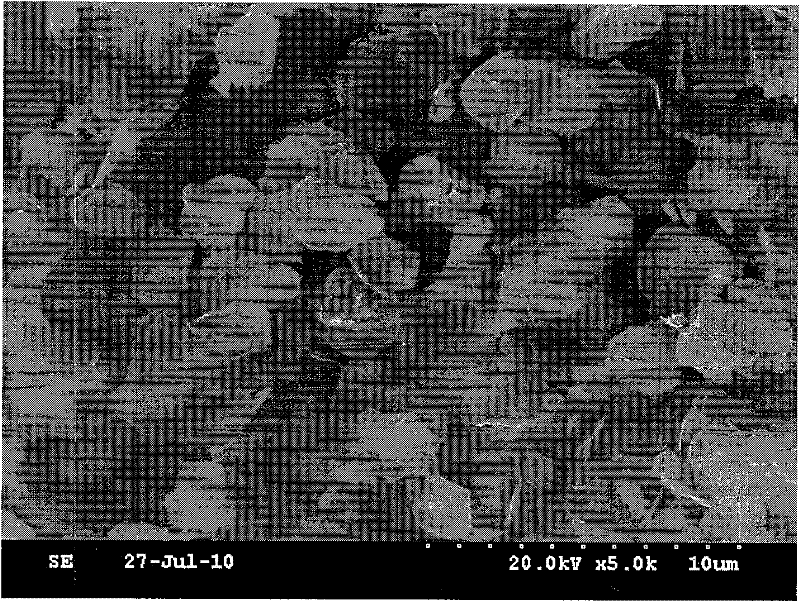

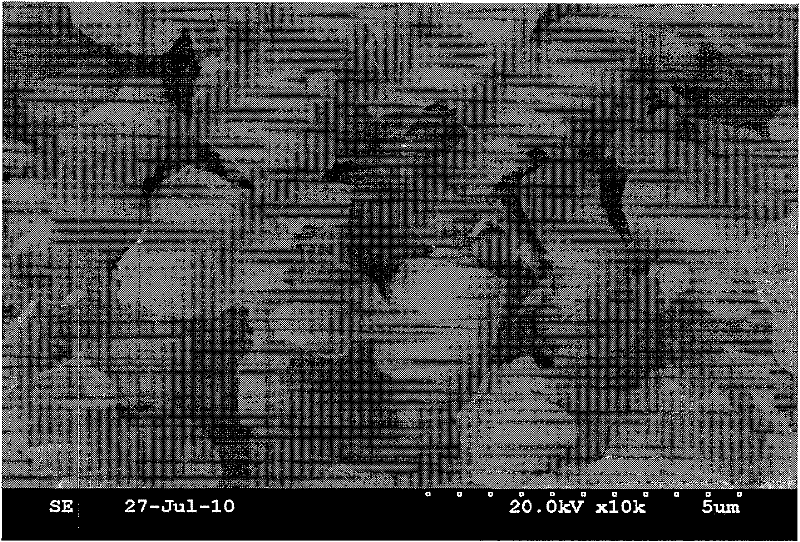

Image

Examples

Embodiment 1

[0028] 1) Measure at least 1000g of water, 540g of silicon source and 340g of ethylamine and mix and stir for 1 hour.

[0029] 2) 60g of aluminum source and 45g of alkali (sodium hydroxide) plus 300g of water were stirred for 1 hour.

[0030] 3) Add the solution in step 2) to the solution in step 1), and stir at 60° C. for 2 hours to form a gel.

[0031] 4) put the gel into the autoclave to supplement the template agent and the directing agent (the directing agent is ZSM-5 molecular sieve, and the quality index of the ZSM-5 molecular sieve directing agent is: molar ratio SiO 2 / Al 2 o 3 ≈300, the crystal powder of ZSM-5 molecular sieve with n-hexane adsorption >130mg / g under 0.1 partial pressure, the grain size of ZSM-5 molecular sieve catalyst is ≤1μm. ), aged at 60°C for 6 hours. The molar ratio of the control gel is:

[0032] SiO 2 : 0.005Al 2 o 3 : 0.6C 2 h 5 NH 2 : 0.12Na 2 O: 10H 2 o

[0033] 5) The above-mentioned gel was kept warm in stages, crystallized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com