Ink amount controller based on calculating feedforward nonlinear compensation control algorithm

A non-linear compensation and control algorithm technology, applied in general parts of printing machinery, printing, printing machines, etc., can solve the problems of blank, increase production cost, backward technology, etc., and achieve the effect of excellent performance and small control cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

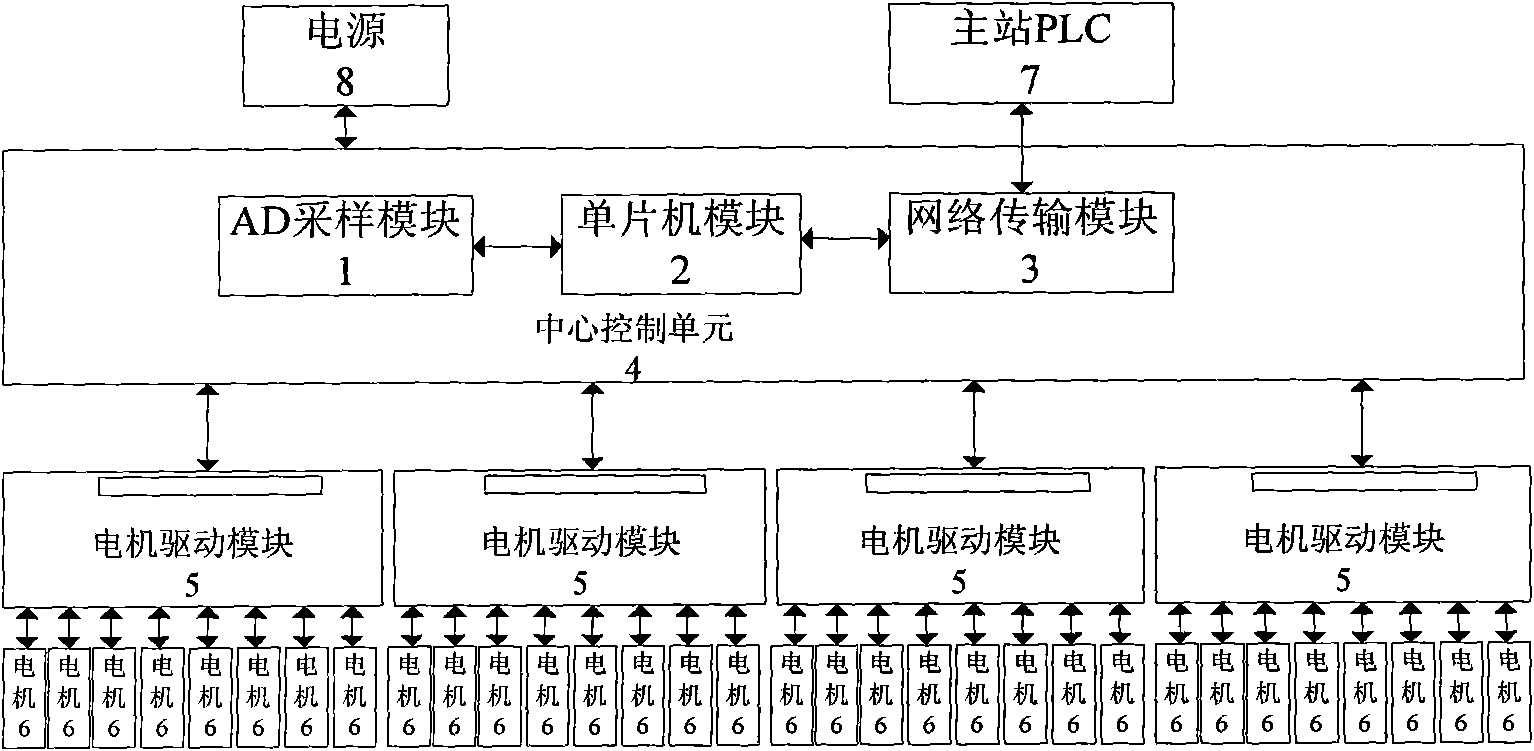

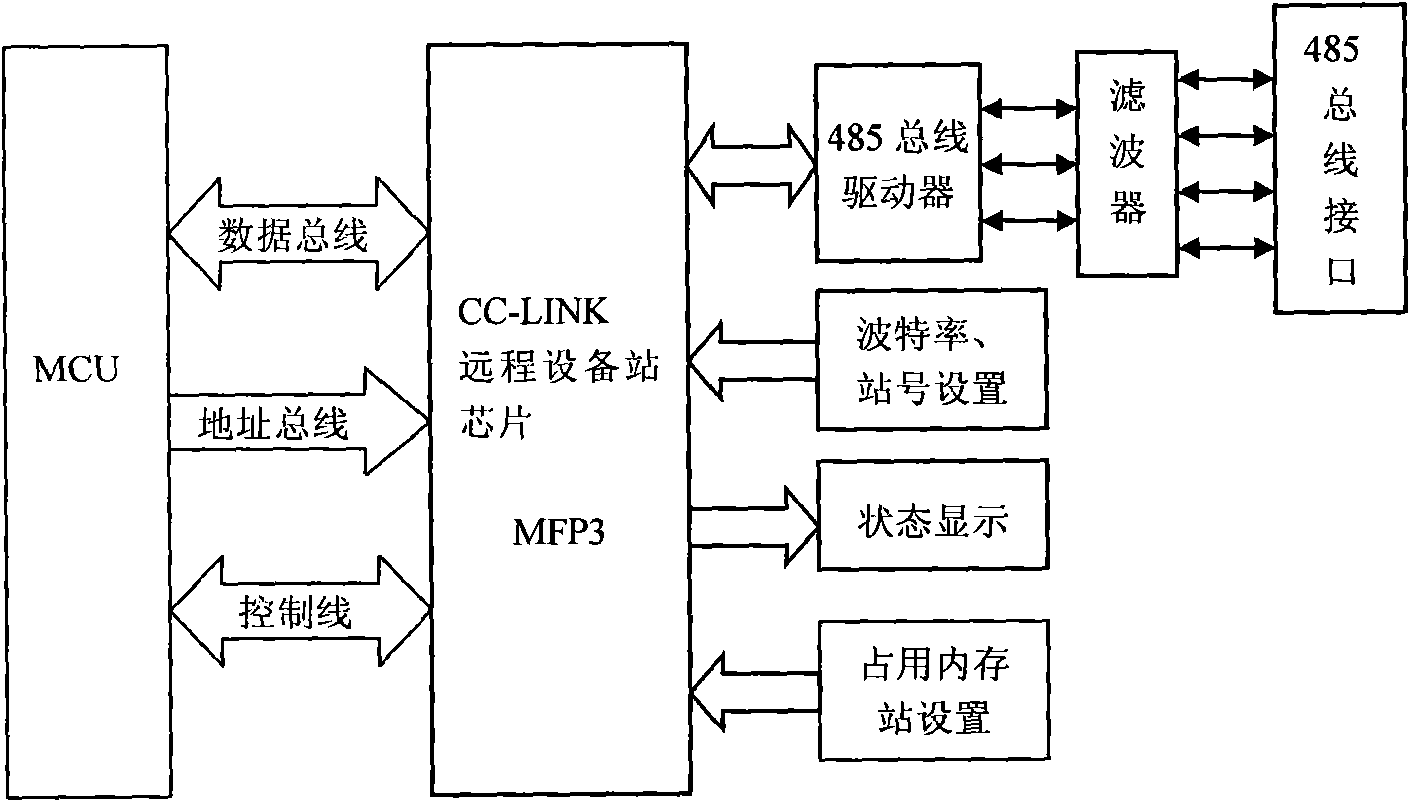

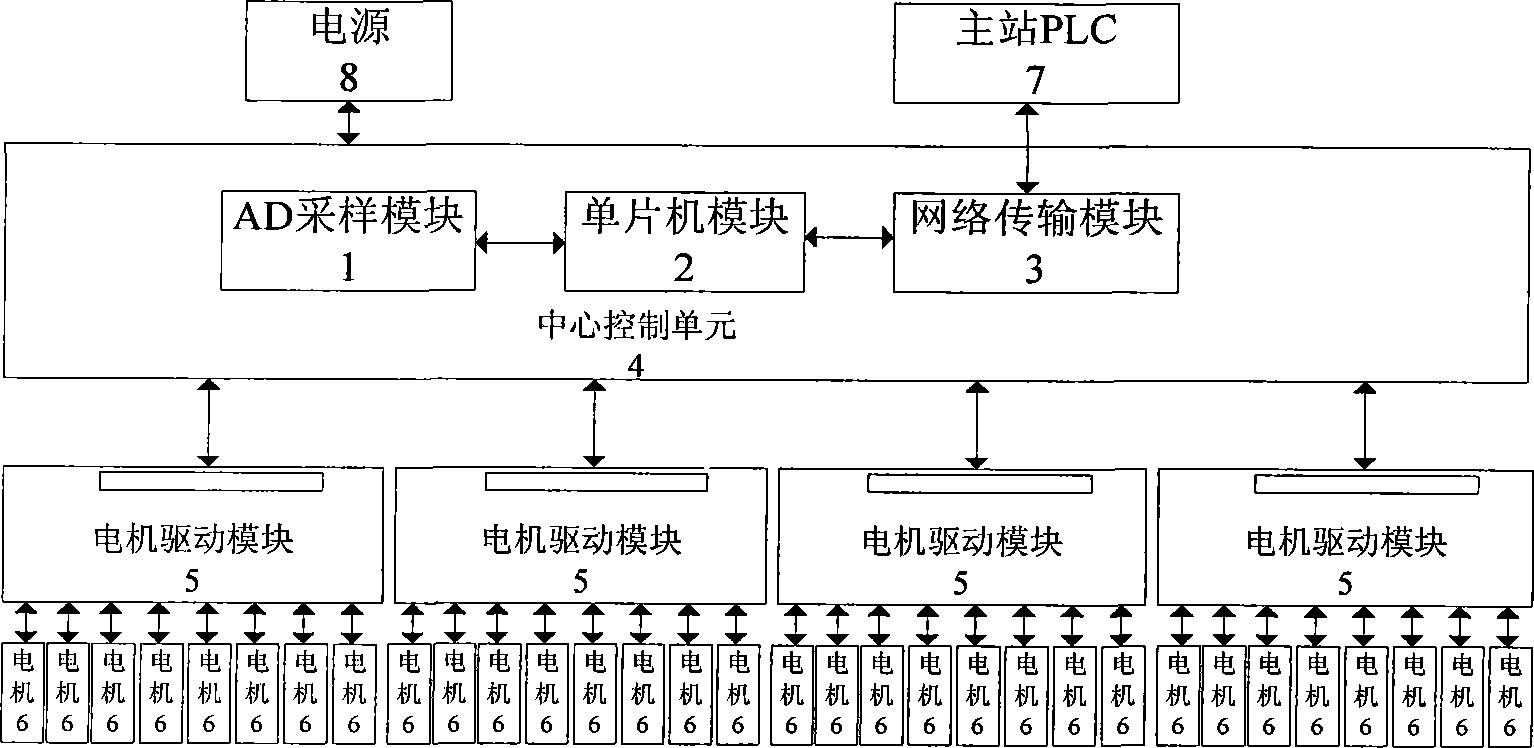

[0040] Such as figure 1 As shown, an ink volume controller based on a computational feedforward nonlinear compensation control algorithm. The controller includes a central control unit 4, a motor drive module 5, and an ink fountain body motor 6. The central control unit 4 includes a single-chip microcomputer module 2 , Network transmission module 3, AD sampling module 1, said network transmission module 3 includes MFP3, CC-Link communication interface, said motor drive module 5 includes a motor drive circuit, a first communication interface, a second communication interface, control The device communicates with the master station PLC7 through the CC-Link communication interface, receives the motor position setting signal, the motor alarm reset signal, and the motor lock flag from the master station PLC7, and collects the ink area ink fountain body (up to It is 64 real position signals, and the central control unit 4 provides the current position feedback value of the motor, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com