Light condensation-light conversion composite reinforced type solar photocatalysis water-decomposition hydrogen-production system

A hydrogen production system and photocatalysis technology, applied in the direction of hydrogen production, energy input, etc., to achieve the effect of high photon conversion efficiency, easy large-scale promotion and application, and enhanced spectral intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

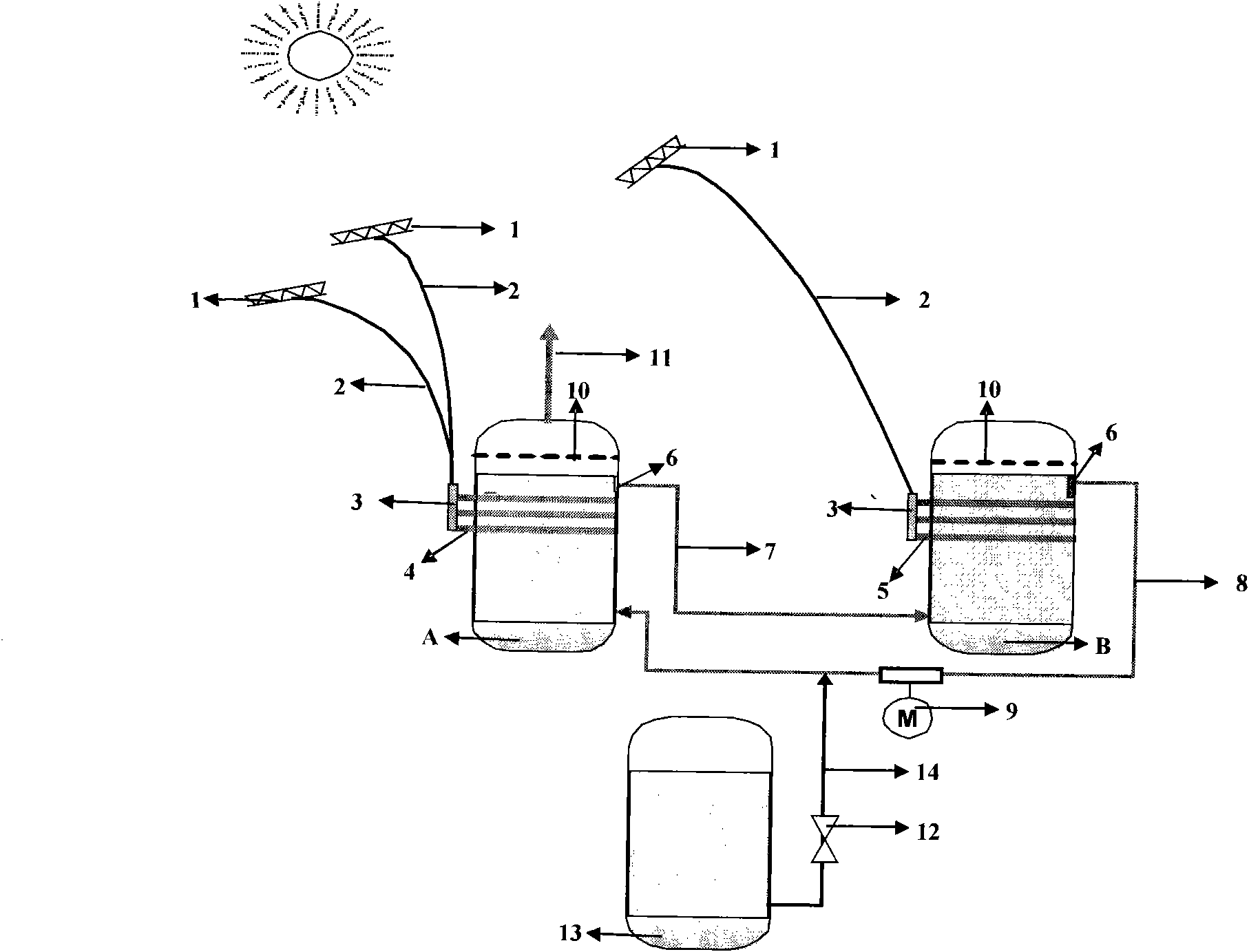

[0023] The structure of the present invention is as figure 1 Shown: It is composed of sunlight collection-transmission unit, light conversion-catalytic hydrogen production reaction unit, light conversion-catalytic oxygen production reaction unit, and medium circulation control unit.

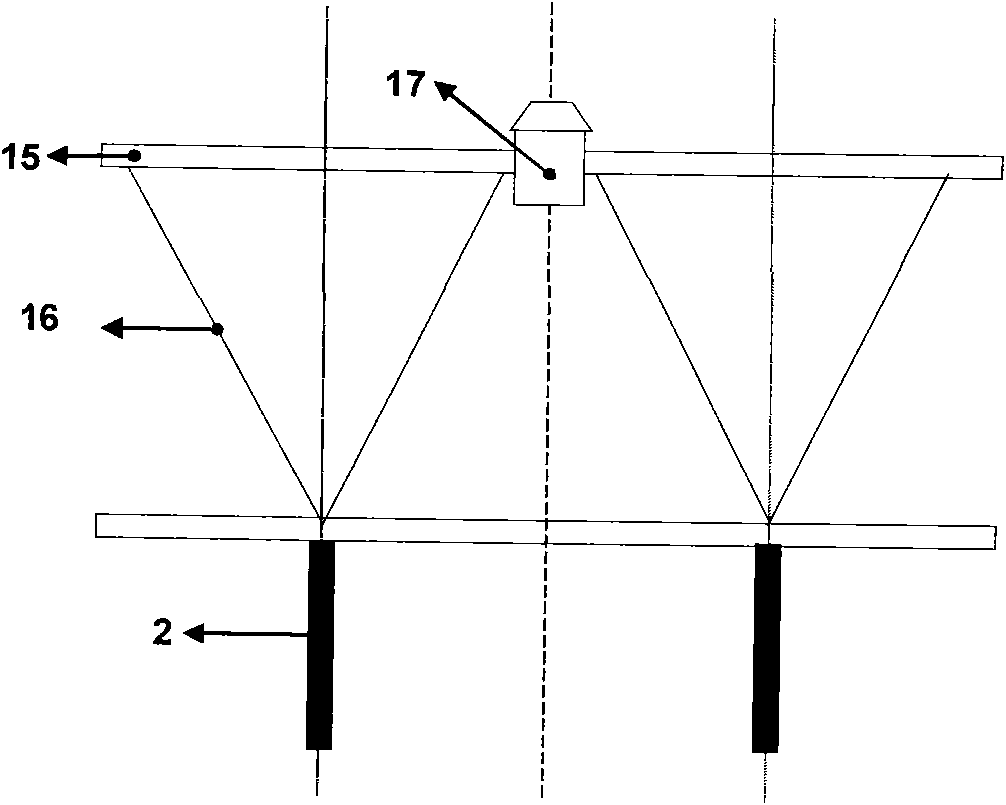

[0024] Sunlight collection-transmission unit (such as figure 2 shown) consists of Fresnel lens (15), concentrator (16), solar automatic tracker (17), and optical fiber (2). The Fresnel lens (15) is above the light concentrator (16), and the bottom of the light concentrator (16) is connected with the light guide fiber (2).

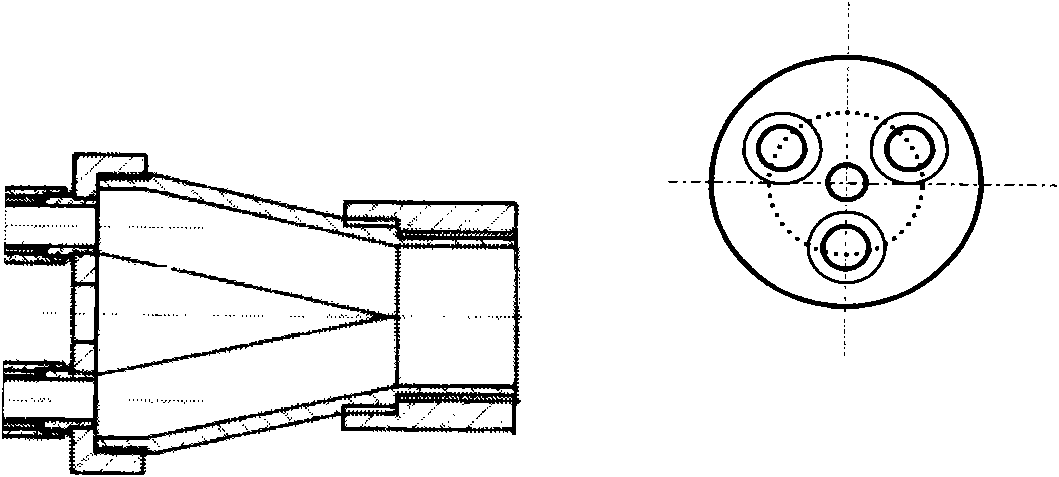

[0025] The photoconversion-catalytic hydrogen production reaction unit is composed of the reactor tank (A), the photoconversion-catalytic hydrogen production reaction array (4), the reaction liquid and the gas separation membrane (6, 10), and the photoconversion-catalytic hydrogen production Reaction array (4) port connector (3, such as image 3 shown) communicates with the ...

Embodiment 2

[0030] The structure of the present invention is as figure 1 Shown: It is composed of sunlight collection-transmission unit, light conversion-catalytic hydrogen production reaction unit, light conversion-catalytic oxygen production reaction unit, and medium circulation control unit.

[0031] Sunlight collection-transmission unit (such as figure 2 shown) consists of Fresnel lens (15), concentrator (16), solar automatic tracker (17), and optical fiber (2). The Fresnel lens (15) is above the light concentrator (16), and the bottom of the light concentrator (16) is connected with the light guide fiber (2).

[0032] The photoconversion-catalytic hydrogen production reaction unit is composed of the reactor tank (A), the photoconversion-catalytic hydrogen production reaction array (4), the reaction liquid and the gas separation membrane (6, 10), and the photoconversion-catalytic hydrogen production Reaction array (4) port connector (3, such as image 3 shown) communicates with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com