Fluorescent photonic crystal thin film and preparation method thereof

A technology of fluorescent photonics and crystals, which is applied in the field of fluorescent photonic crystal thin films and its preparation, can solve the problems of unstable fluorescent performance, complex synthesis of quantum dots, cumbersome operation process, etc., and achieve short preparation cycle, bright structural color, and enhanced spectral intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

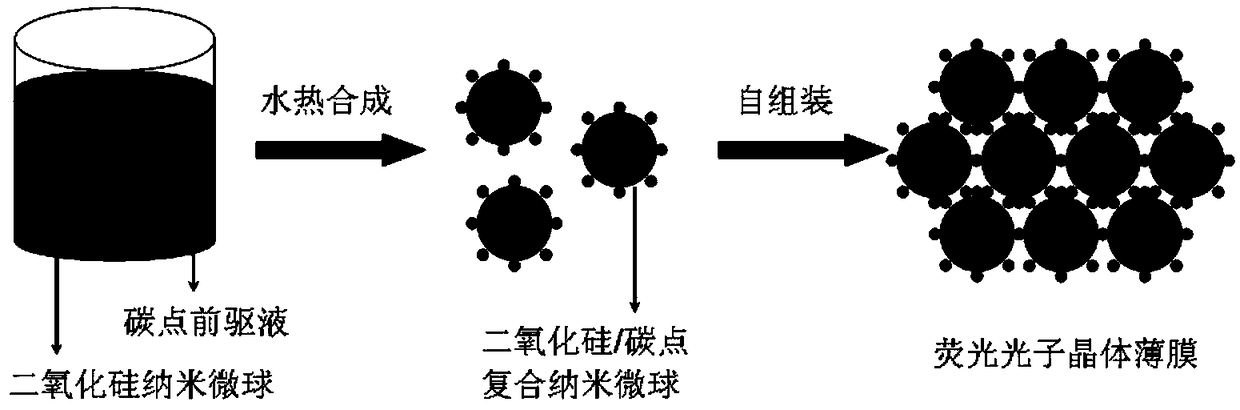

[0032] The present invention provides a method for preparing a fluorescent photonic crystal film, which comprises the following steps:

[0033] (1) Preparation of monodisperse silica nano-microspheres: firstly mix tetraethyl orthosilicate and absolute ethanol, then mix deionized water, ammonia water, and absolute ethanol with the previous solution, and magnetically stir the reaction at room temperature 20 hours; centrifugally wash with ethanol three times to obtain the monodisperse silica nano-microspheres;

[0034] (2) Preparation of composite nano-microspheres: the monodisperse silica nano-microspheres obtained in step (1) and the precursor liquid for preparing carbon quantum dots are uniformly mixed in an autoclave, and reacted at 180° C. for 4-5 hours . After the reaction, it is cooled to room temperature, and centrifugally washed with ethanol for three times to obtain the nanocomposite microspheres;

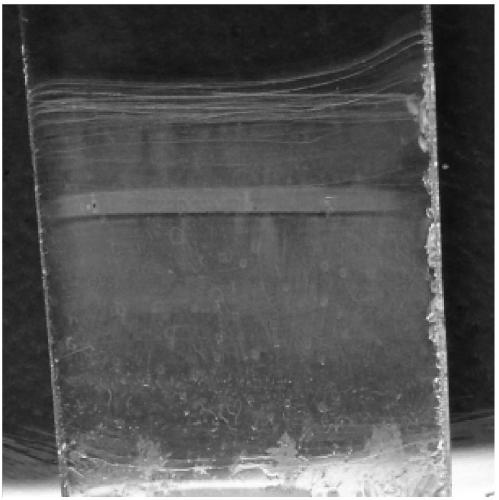

[0035] (3) Preparation of fluorescent photonic crystal thin film: Dis...

Embodiment 1

[0074] Example 1 Preparation of blue fluorescent photonic crystal thin film

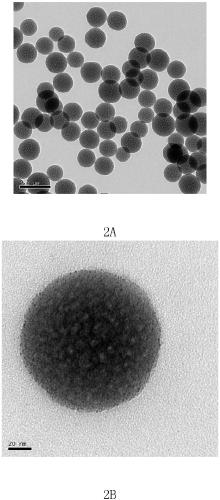

[0075] A blue fluorescent photonic crystal film comprising monodisperse silica nanospheres and carbon quantum dots, see figure 2 ; The particle size of the silica nano-microspheres is 170 nm, and the particle size of the carbon quantum dots is 2 nm. The ratio of ammonia water, deionized water and tetraethyl orthosilicate used in the preparation of monodisperse silica nano-microspheres is 1.85:1.39:1.

[0076] (1) Preparation of monodisperse silica nanospheres: firstly mix 2.08mL of tetraethyl orthosilicate and 50mL of absolute ethanol, and then mix 2.91mL of deionized water, 3.85mL of ammonia water, and 40mL of absolute ethanol. , the above two solutions were mixed at room temperature and under magnetic stirring, and the reaction was continuously stirred for 20 hours. After the reaction, it was washed three times by ethanol centrifugation.

[0077] (2) Preparation of monodisperse silica / carbon qu...

Embodiment 2

[0079] Example 2 Preparation of Green Fluorescent Photonic Crystal Films

[0080] A green fluorescent photonic crystal film, comprising monodisperse silica nano-microspheres and carbon quantum dots; the particle diameter of the silica nano-microspheres is 230 nm, and the particle diameter of the carbon quantum dots is 2 nm. The ratio of ammonia water, deionized water and tetraethyl orthosilicate used in the silicon nanospheres is 1.85:1.44:1.

[0081](1) Preparation of monodisperse silica nanospheres: firstly mix 2.08mL of tetraethyl orthosilicate with 50mL of absolute ethanol, and then mix 3.0mL of deionized water, 3.85mL of ammonia water, and 40mL of absolute ethanol. , the above two solutions were mixed at room temperature and under magnetic stirring, and the reaction was continuously stirred for 20 hours. After the reaction, it was washed three times by ethanol centrifugation.

[0082] (2) Preparation of monodisperse silica / carbon quantum dot composite nano-microspheres:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com