Method for treating waste water from copper smelting by using modified ardealite

A phosphogypsum and copper smelting technology, which is applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as odor generation, undrinkable water quality, etc., and achieve low treatment costs, The effect of low cost, automatic control and increased degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

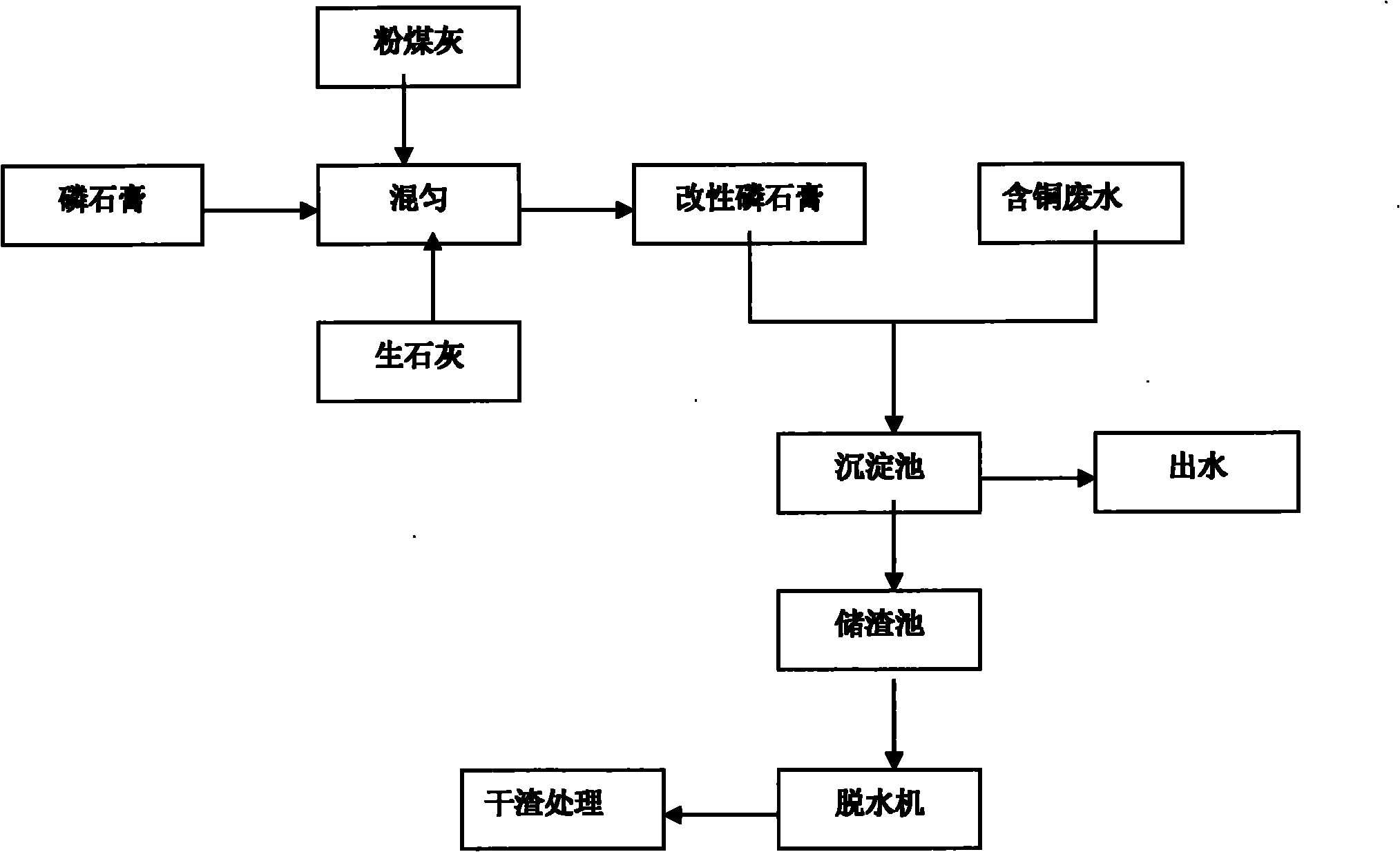

[0047] (2) Preparation of modified phosphogypsum

[0048] Add a modifier to the phosphogypsum, the modifier is quicklime and fly ash, and the ratio of addition is: 55% to 65% of phosphogypsum, 25 to 45% of fly ash, 5 to 10% of quicklime, and mix well;

[0049] (3) Adsorption research

[0050] Modified phosphogypsum at 10kg / m 3 Add the amount of copper smelting waste water, mix and stir, filter after contacting for 1 hour, and measure the content of copper, zinc, cadmium and other ions in the filtrate after treatment. Use an atomic absorption spectrophotometer to measure the content of copper, zinc, cadmium and other ions in the effluent, and use the subtraction method to calculate the amount of heavy metals adsorbed by the adsorption material.

[0051] (4) Treatment of adsorbent

[0052] The adsorbent is dehydrated after precipitation, and can be used as building material after drying. Such as the production of building gypsum board, gypsum powder, etc. The wastewater use...

Embodiment 1

[0054] Embodiment 1: the modified phosphogypsum is mixed with 5kg / m 3 Add the above-mentioned amount of smelting wastewater, mix and stir, filter after 40 minutes of contact, measure the content of copper in the treated filtrate to be 10mg / L, the content of zinc to be 7mg / L, the content of lead to be 2mg / L, the content of cadmium The content is 1mg / L.

Embodiment 2

[0055] Embodiment 2: with modified phosphogypsum at 10kg / m 3 Add the above-mentioned smelting wastewater, mix and stir, filter after contacting for 1 hour, measure the content of copper in the treated filtrate to be 4 mg / L, the content of zinc to be 5 mg / L, the content of lead to be 1.2 mg / L, and the content of cadmium to be 1.2 mg / L. The content is 0.5mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com