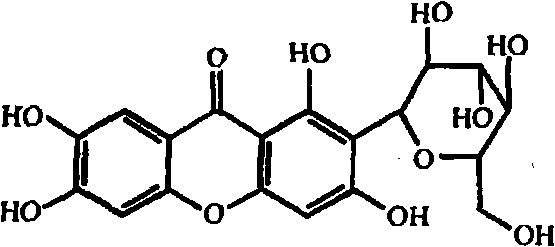

Method for preparing mangiferin

A mangiferin and aqueous solution technology, applied in the direction of organic chemistry, can solve the problems of operator and environmental damage, many mangiferin impurities, complicated operation process and other problems, and achieve the effects of low production cost, less impurities and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Will be weighed as 500kg of mango leaves, placed in the extraction pot, add 5000L of 5% sodium hydroxide aqueous solution, boil for 50 minutes, filter the extract for use, then add 5000L of 5% sodium hydroxide solution Sodium hydroxide aqueous solution, boiled for 30 minutes, combined the two filtered extracts, then added hydrochloric acid to it, until the pH of the filtered extract was about 1, let it stand for 2 hours, precipitated impurities, filtered to remove impurities , the filtrate is enriched through a neutral macroporous resin column, and then the mangiferin enriched on the neutral macroporous resin column is eluted with a volume concentration of 70% ethanol aqueous solution 2000L, and the eluate is passed through another A kind of basic macroporous resin column is carried out decolorization treatment, the eluent after decolorization treatment is concentrated, reclaims ethanol wherein, the semi-finished product obtained at this moment already is to contain 75% ...

Embodiment 2

[0029] Put 300kg of almond leaves in the extraction pot, add 3000L of 7% sodium hydroxide aqueous solution, boil for 50 minutes, filter the extract for later use, then add 3000L of 7% sodium hydroxide Aqueous solution, boiled for 30 minutes, combined the two filtered extracts, then added hydrochloric acid to it, until the pH of the filtered extract was about 2, let it stand for 3 hours, precipitated impurities, filtered to remove impurities, and the filtrate was passed through The neutral macroporous resin column is enriched, and then the mangiferin enriched on the neutral macroporous resin column is eluted with a volume concentration of 70% ethanol aqueous solution 1500L, and the eluate is passed through another alkaline The macroporous resin column is subjected to decolorization treatment, the eluent after the decolorization treatment is concentrated, and the ethanol therein is recovered, and the semi-finished product obtained contains 71% mangiferin, and is then dissolved in...

Embodiment 3

[0031]Weigh 400kg of immature fruit of almond leaves, remove the core, place in the extraction pot, add 4000L of 9% sodium hydroxide aqueous solution, boil for 50 minutes, filter the extract for later use, then add 4000L of 9% sodium hydroxide solution It is 9% sodium hydroxide aqueous solution, boil for 30 minutes, combine the extracts filtered out twice, then add hydrochloric acid to it, until the pH of the filtered extract is about 1.5, let it stand for 2 hours, and precipitate impurities , filter to remove impurities, and the filtrate is enriched through a neutral macroporous resin column, and then 2000L of ethanol aqueous solution with a volume concentration of 70% is used to elute the mangiferin enriched on the neutral macroporous resin column, and the eluent Then pass another basic macroporous resin column for decolorization treatment, concentrate the eluate after decolorization treatment, and precipitate crystals to obtain the crude product, then dissolve it to saturati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com