Method and device for simulating straw compression molding

A technology of compression molding and compression devices, which is applied in the direction of measuring devices, mechanical devices, and preparation of test samples. It can solve the problems of resource waste, long cycle time, and high cost, and achieve easy disassembly and installation, simple structure, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

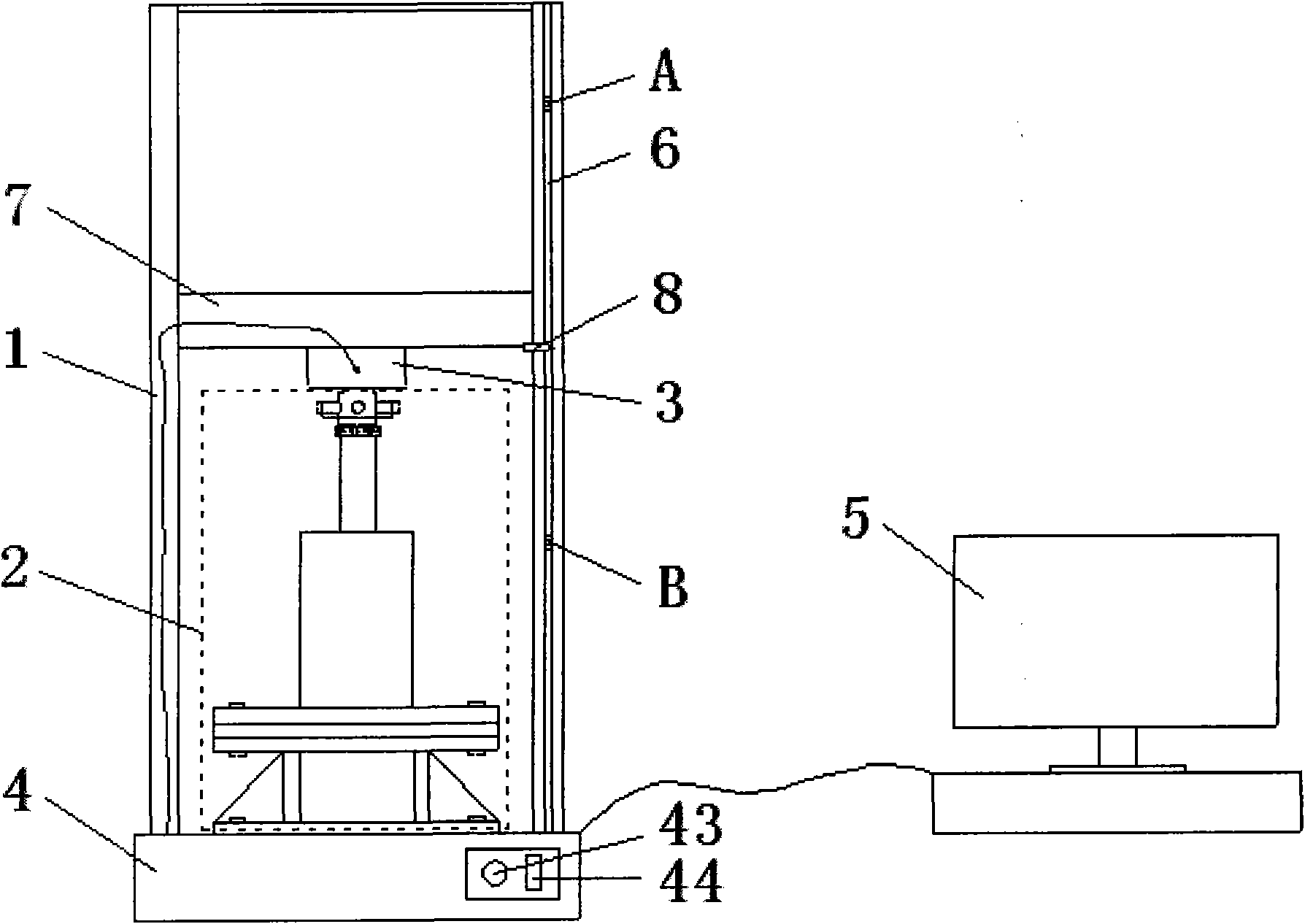

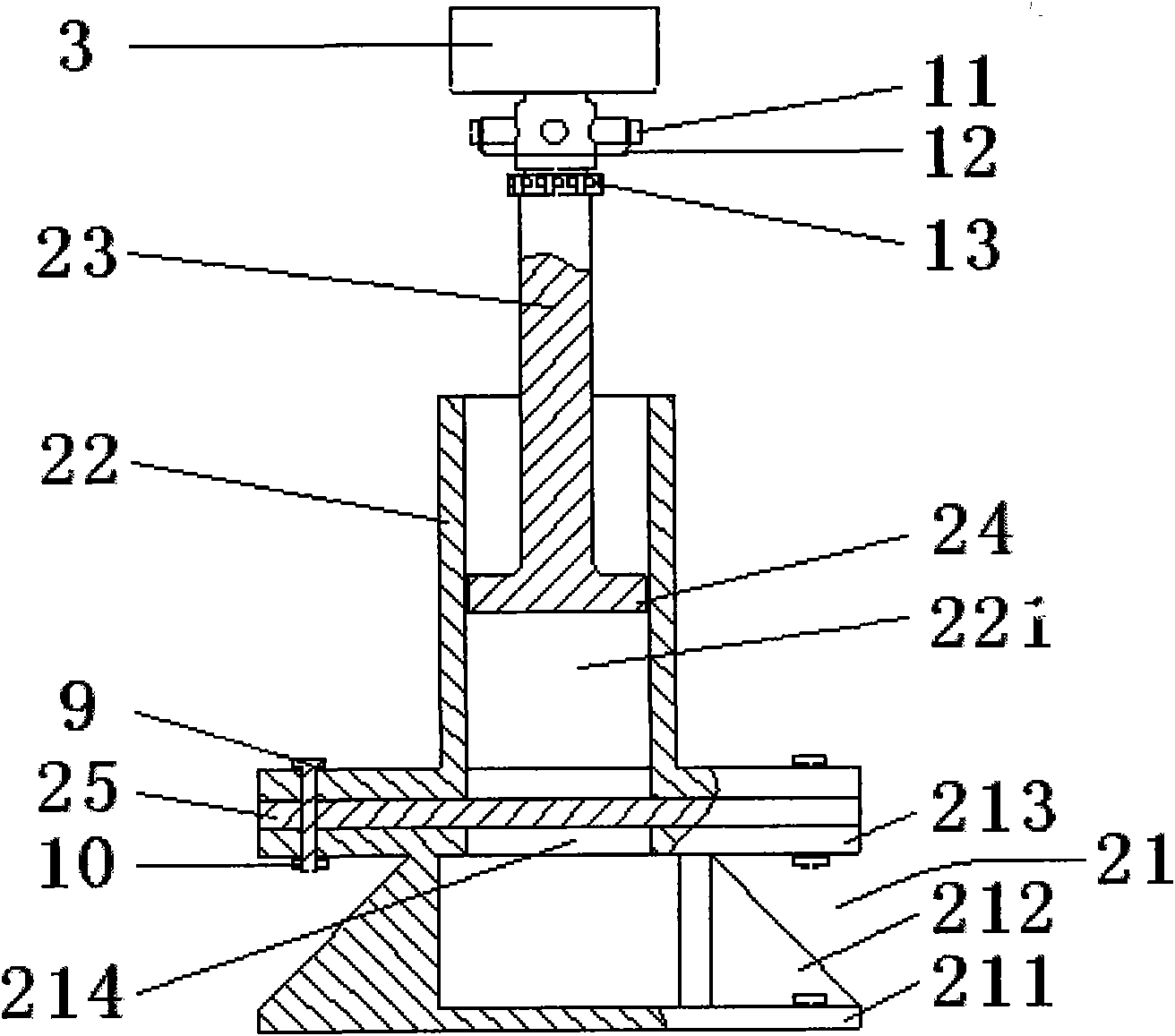

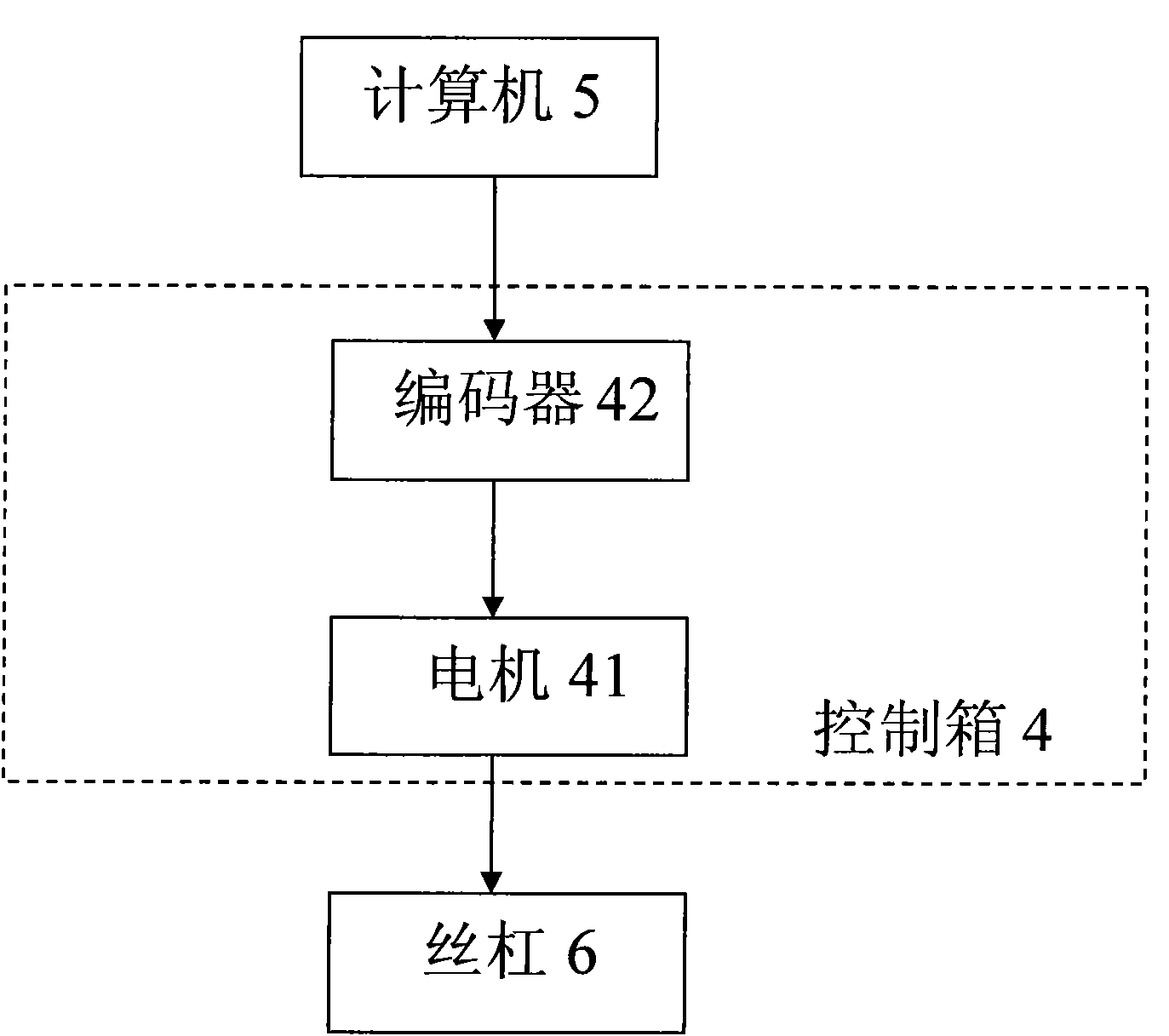

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] The inventive method comprises the following steps:

[0027] 1) Remove the leaves and roots of the selected straw, take a little of the straw and cut it short and dry it as a sample, cut it to 30-40mm, the drying temperature of the sample is 65°C, the drying time is 48h, and the The physical and chemical indicators such as hemicellulose, cellulose, acid-washed lignin, crude ash and moisture content of the samples were measured and analyzed, and the measured hemicellulose, cellulose, acid-washed lignin and crude ash were used as the variety characteristics of the straw.

[0028] 2) The remaining straw in step 1) is used as the object to be compressed, first air-dried to a moisture content of 10% to 15%, and then shortened according to the diameter of the compression cylinder, and then the straw to be compressed is rehydrated, Adjust the moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com