Silicon transverse device on N-type insulator for improving current density and preparation process thereof

A silicon-on-insulator, lateral device technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effect of increasing current density, increasing device current, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

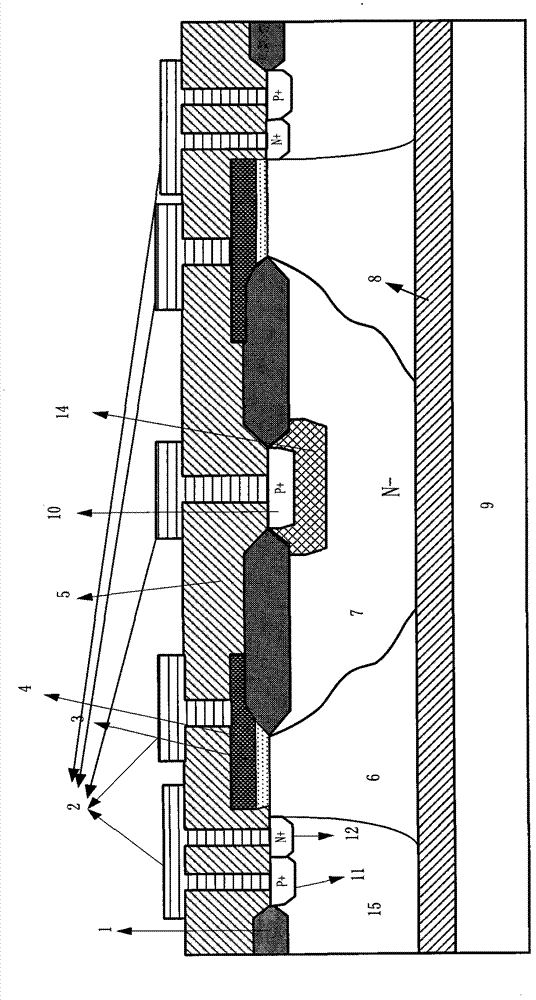

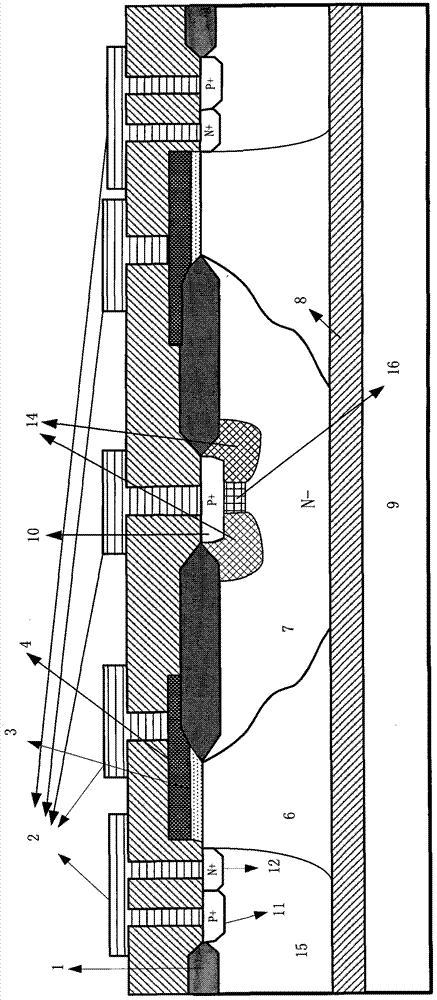

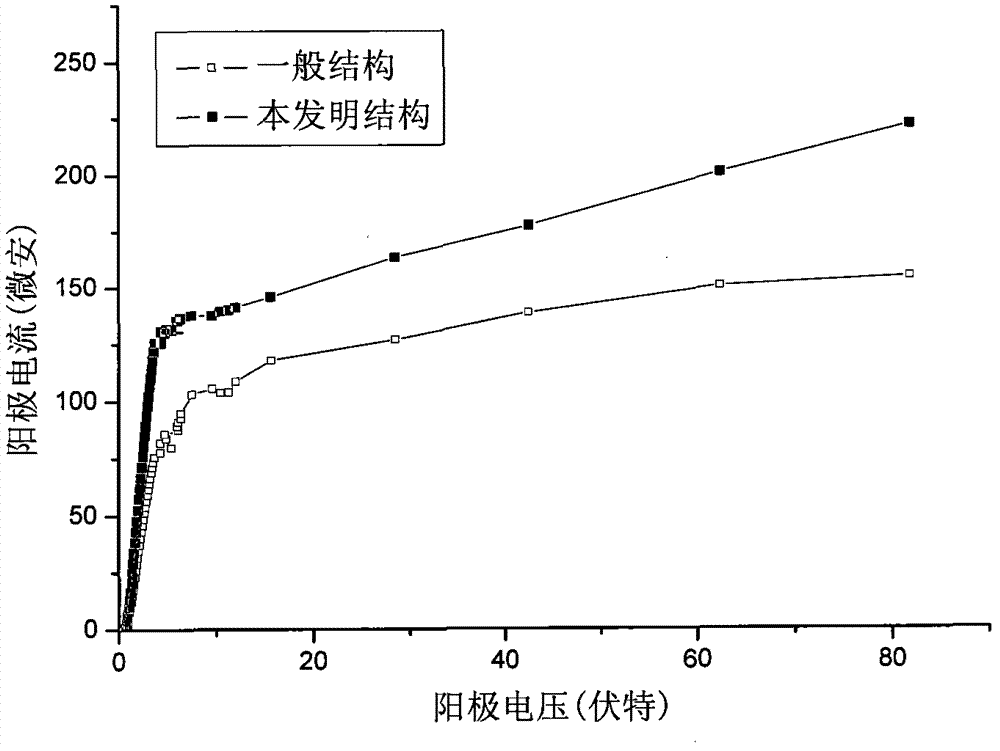

[0035] refer to figure 2 , an N-type silicon-on-insulator lateral device for increasing current density, comprising: a P-type semiconductor substrate 9 is provided with a buried oxide layer 8 on the semiconductor substrate 9, a P epitaxial layer 6 is provided on the buried oxide layer 8, and The P epitaxial layer is provided with an N-type drift region 7 and a P-type well region 15, and an N-type source region 12 and a P-type contact region 11 are arranged on the surface of the P-well region 15, and an N-type drift region 7 is provided on the N-type drift region 7. The buffer zone 14 is provided with a P-type drain region 10 above the N-type buffer zone 14, and a gate oxide layer 3 is also provided on the surface of the P epitaxial layer 6, and the gate oxide layer 3 extends from the P epitaxial layer 6 to the N-type drift Region 7, in the N-type source region 12 and the P-type contact region 11 on the surface of the type P well region 15, a field oxide layer 1 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com