Control method of sine wave linear motor for feed driving of high-precision numerical control machine

A technology of CNC machine tools and linear motors, which is used in motor generator control, generator control, electronic commutation motor control, etc. The effect of improving stability and precision, and improving dynamic responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

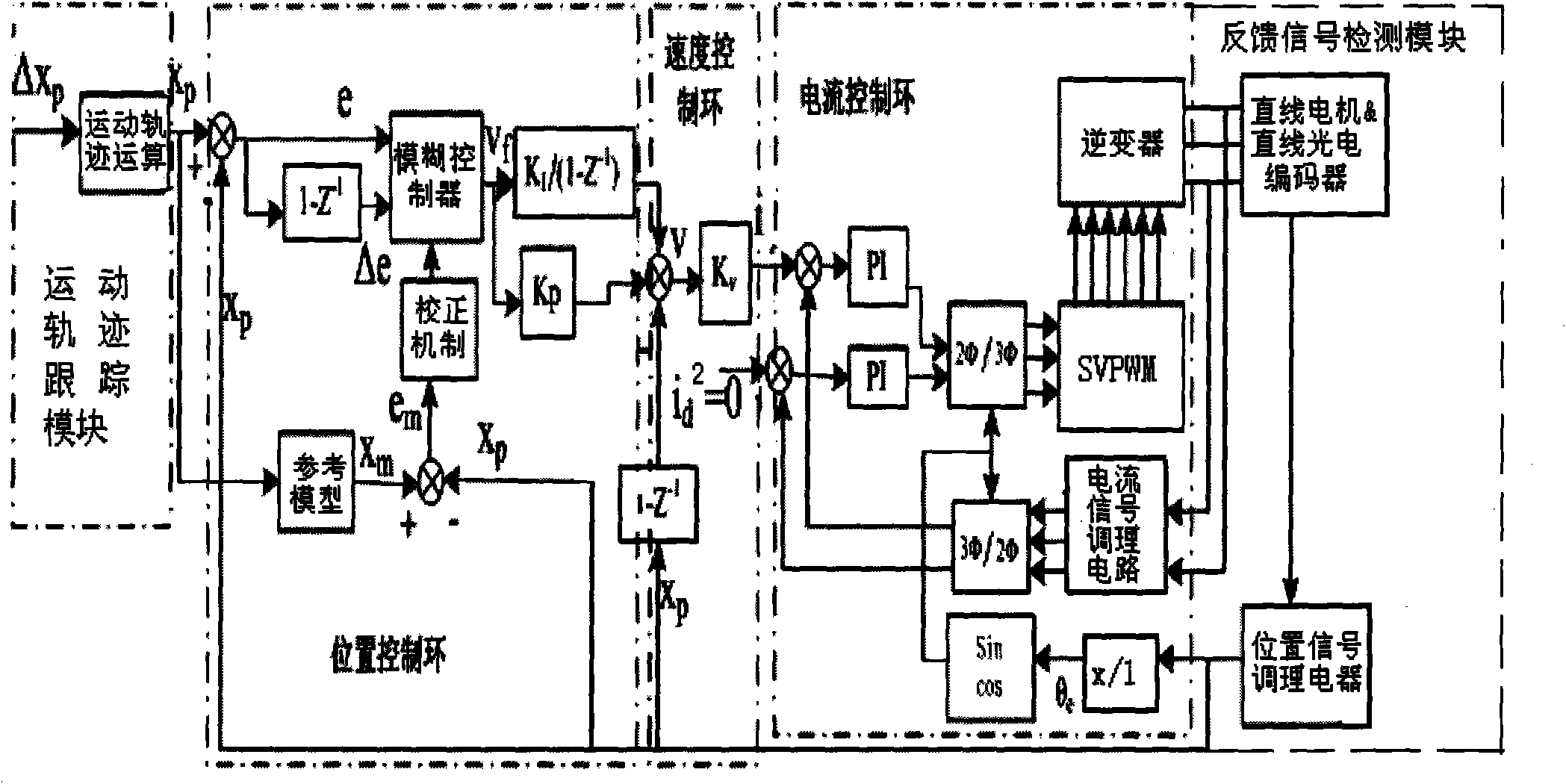

[0023] A control method of a sine wave linear motor for high-precision numerical control machine tool feed drive according to the present invention, specifically comprising the following steps:

[0024] The motion trajectory tracking module compares the generated displacement reference command with the collected real-time displacement signal, and transmits the generated displacement error E and error change rate dE to the position control loop;

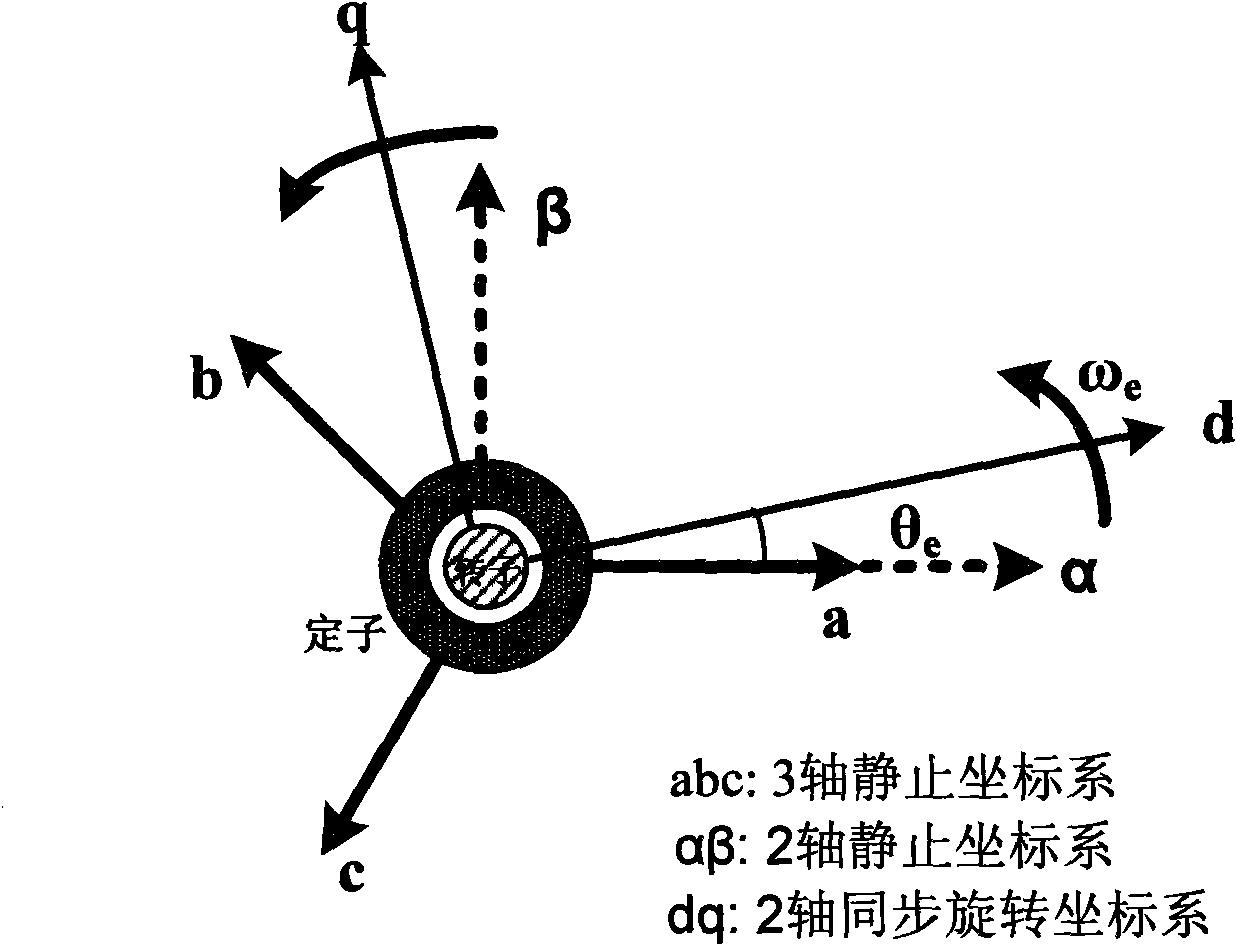

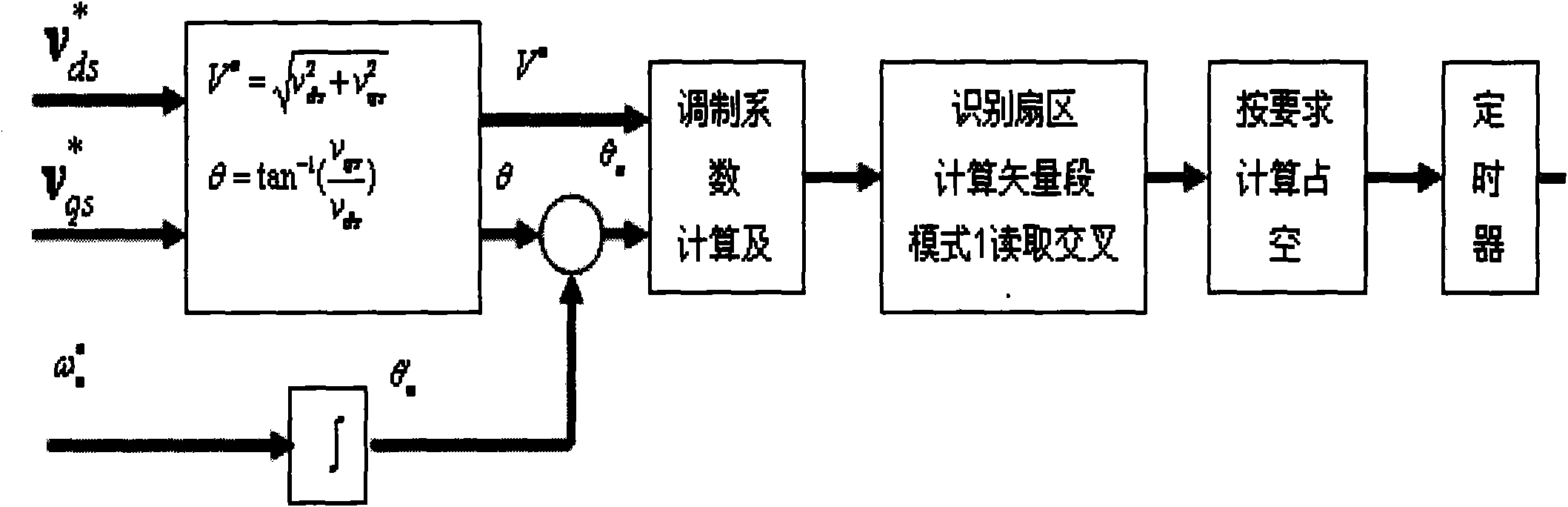

[0025] The position control loop adopts the self-adaptive fuzzy control algorithm. Firstly, the two input quantities are fuzzified, and the fuzzy inference is carried out by using the product reasoning machine according to the established fuzzy rules. After defuzzification, the output of the fuzzy controller can be obtained; at the same time, the displacement The reference command is also compared with the real-time displacement signal collected by a second-order reference model, and the generated displacement error is used to correct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com