Dry dedusting and sensible heat recovery system for electric furnace flue gas

A technology of dry dust removal and sensible heat recovery, which is applied in furnaces, combustion methods, waste heat treatment, etc., can solve the problems of unstable flue gas of electric furnaces, contamination of heating surfaces, and unsatisfactory effects, so as to improve energy recovery rate and ensure Capture rate, effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

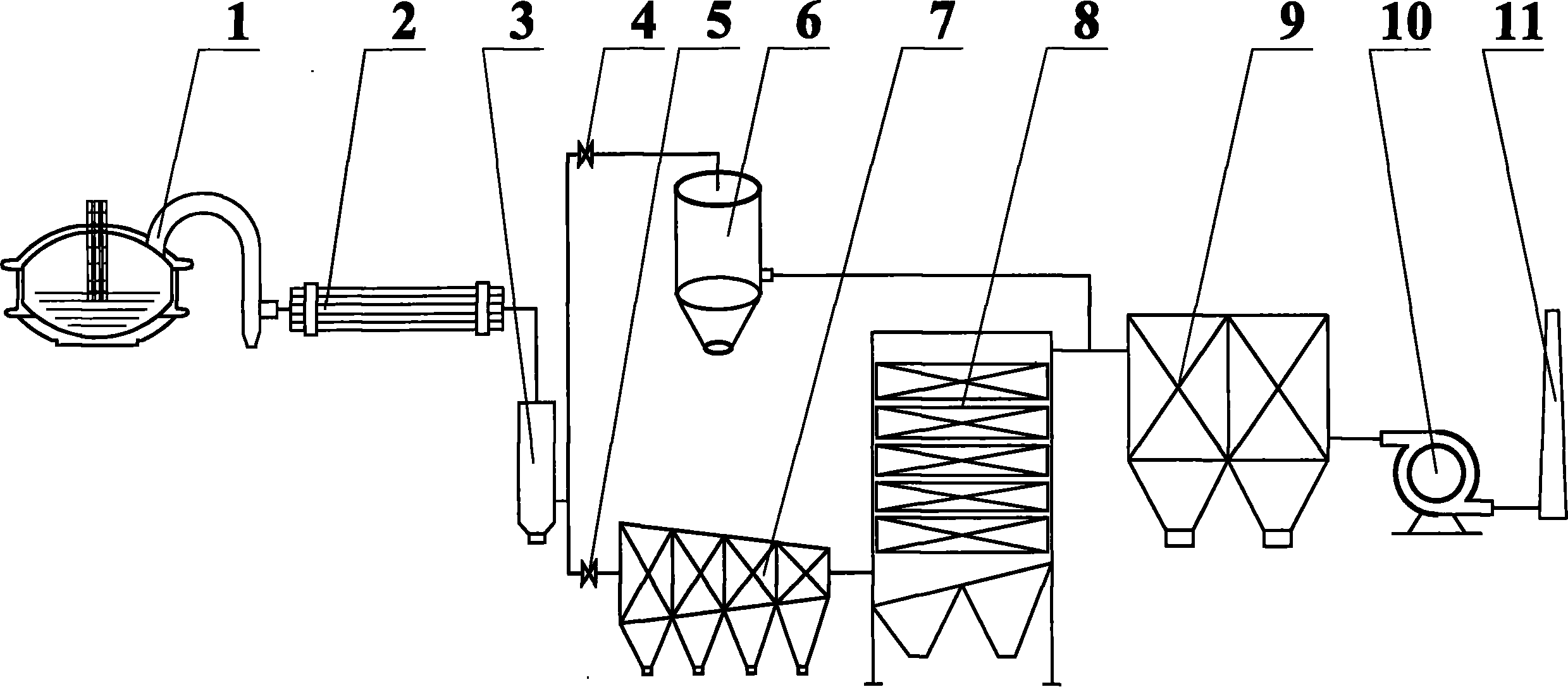

[0022] Such as figure 1 As shown, the embodiment of the present invention provides a dry dust removal system for electric furnace flue gas and its sensible heat recovery system, which includes a main road and a parallel branch road, and the main road includes a front main road and a rear main road, wherein the front main road includes Connected primary settling chamber 1, vaporization cooling flue 2 and secondary settling chamber 3, the rear main road includes low-temperature dust collector 9, frequency conversion induced draft fan 10 and chimney 11 connected in sequence; the parallel branch includes the first branch arranged in parallel And the second branch, the spray cooling tower 6 is set on the first branch, and the second branch includes the high-temperature dust collector 7 and the waste heat boiler 8 connected in sequence; the parallel branch is set between the front main road and the rear main road to form whole system. This system removes the original water-cooled f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com