Preparation method of phosphate luminescent material

A luminescent material and phosphate technology, which is applied in the field of preparation of phosphate luminescent materials, can solve the problems of reducing calcination temperature and calcination time, and poor particle size uniformity of products, so as to achieve lower calcination temperature, good product performance consistency, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a phosphate luminescent material, wherein the phosphate is a single metal cation phosphate or a single-phase multi-metal cation phosphate;

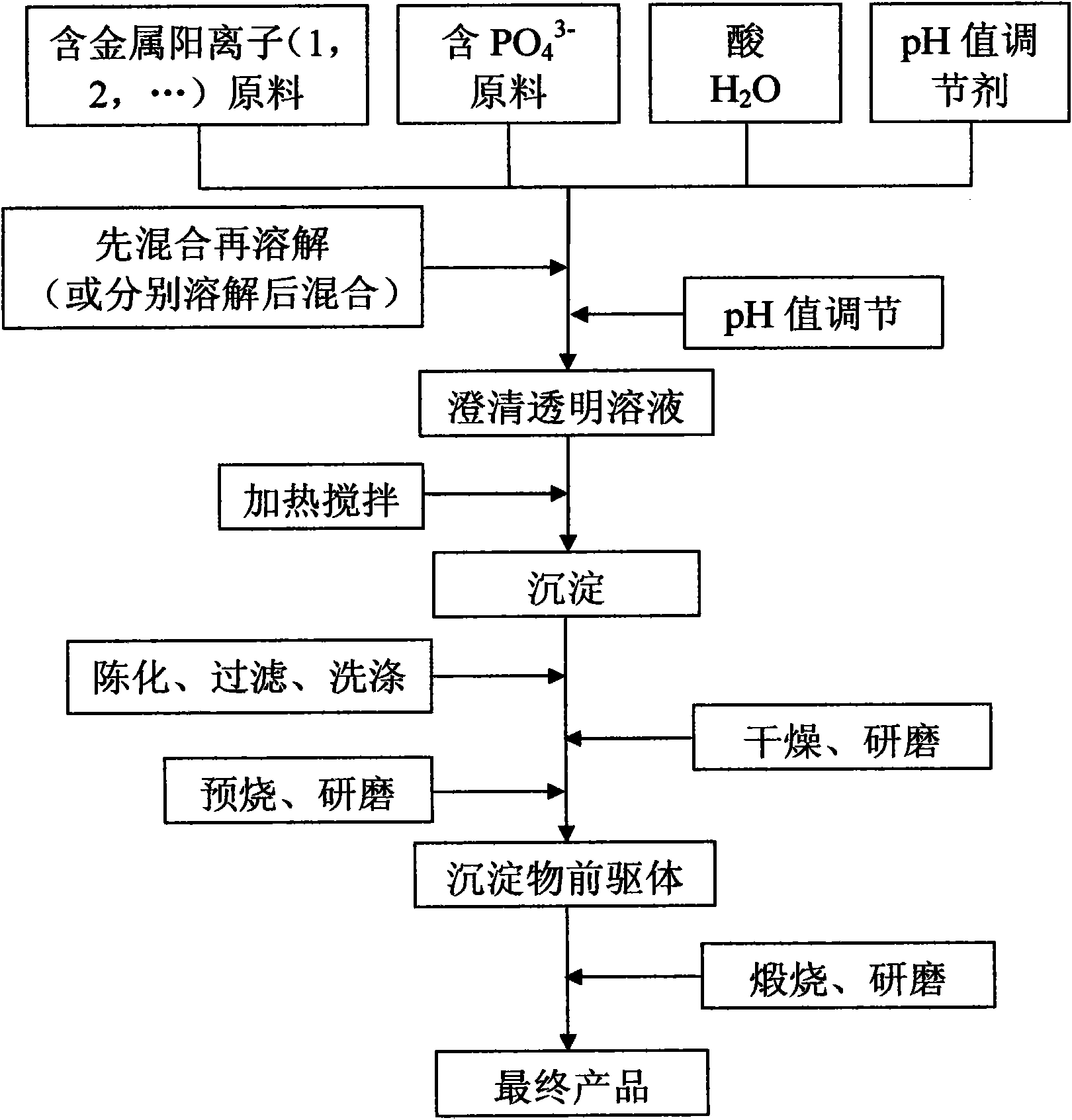

[0029] Such as figure 1 Shown, its preparation method comprises the following steps:

[0030] Step 1, prepare raw materials and pH regulator:

[0031] According to the phosphate molecular formula to be prepared PO 4 3- Take raw material A and raw material B with the mol ratio of metal cation;

[0032] The raw material A contains PO 4 3- Substances that are soluble in acid or water;

[0033] The raw material B contains metal cations corresponding to the phosphate to be prepared, is soluble in acid or water and is compatible with PO 4 3- Substances that can directly react to form phosphate precipitates that are insoluble in the aqueous liquid phase system;

[0034] The pH regulator is urea or hexamethylenetetramine;

[0035] Step 2,

[0036] After mixing raw material A, raw mat...

Embodiment 1

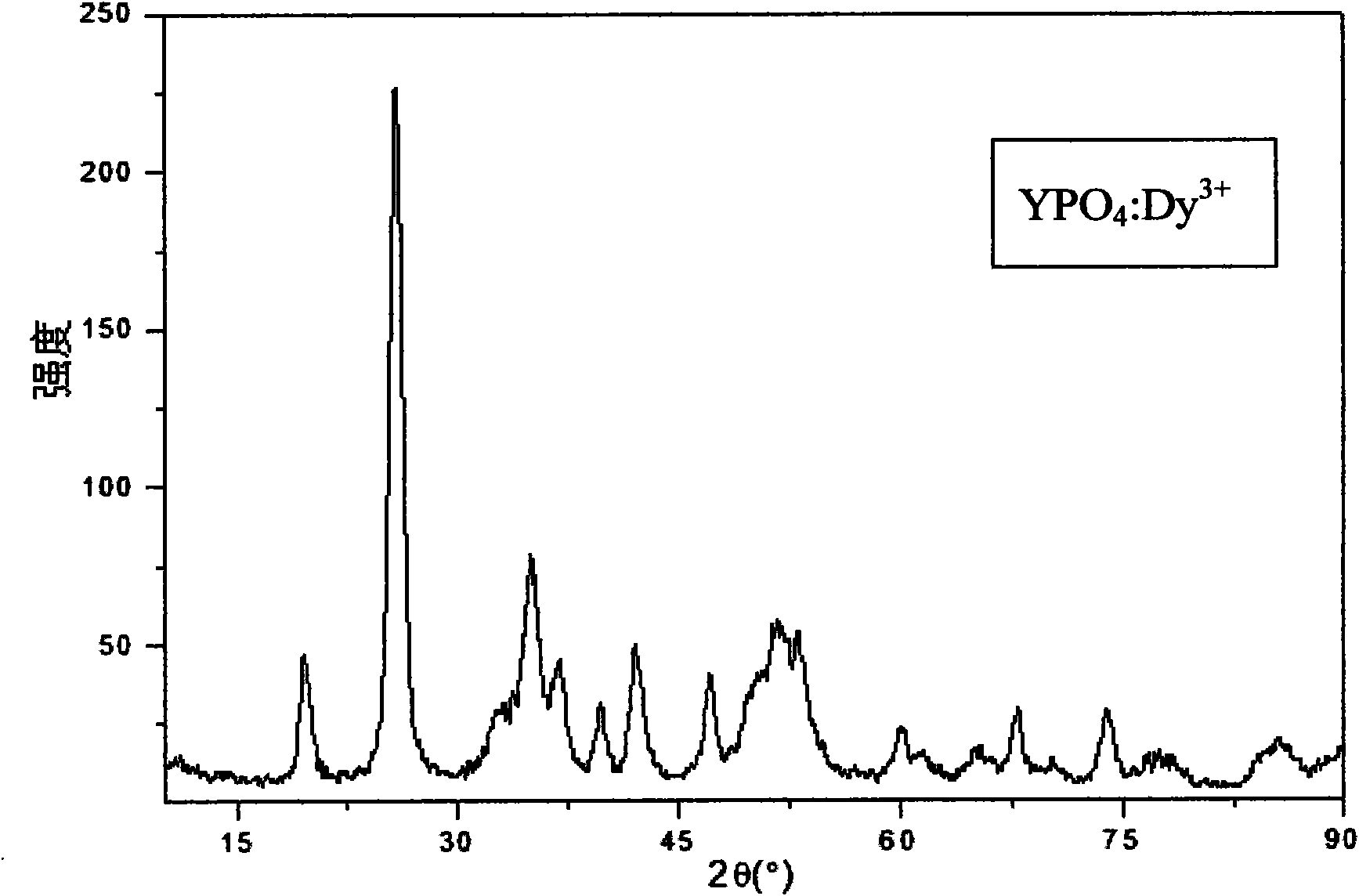

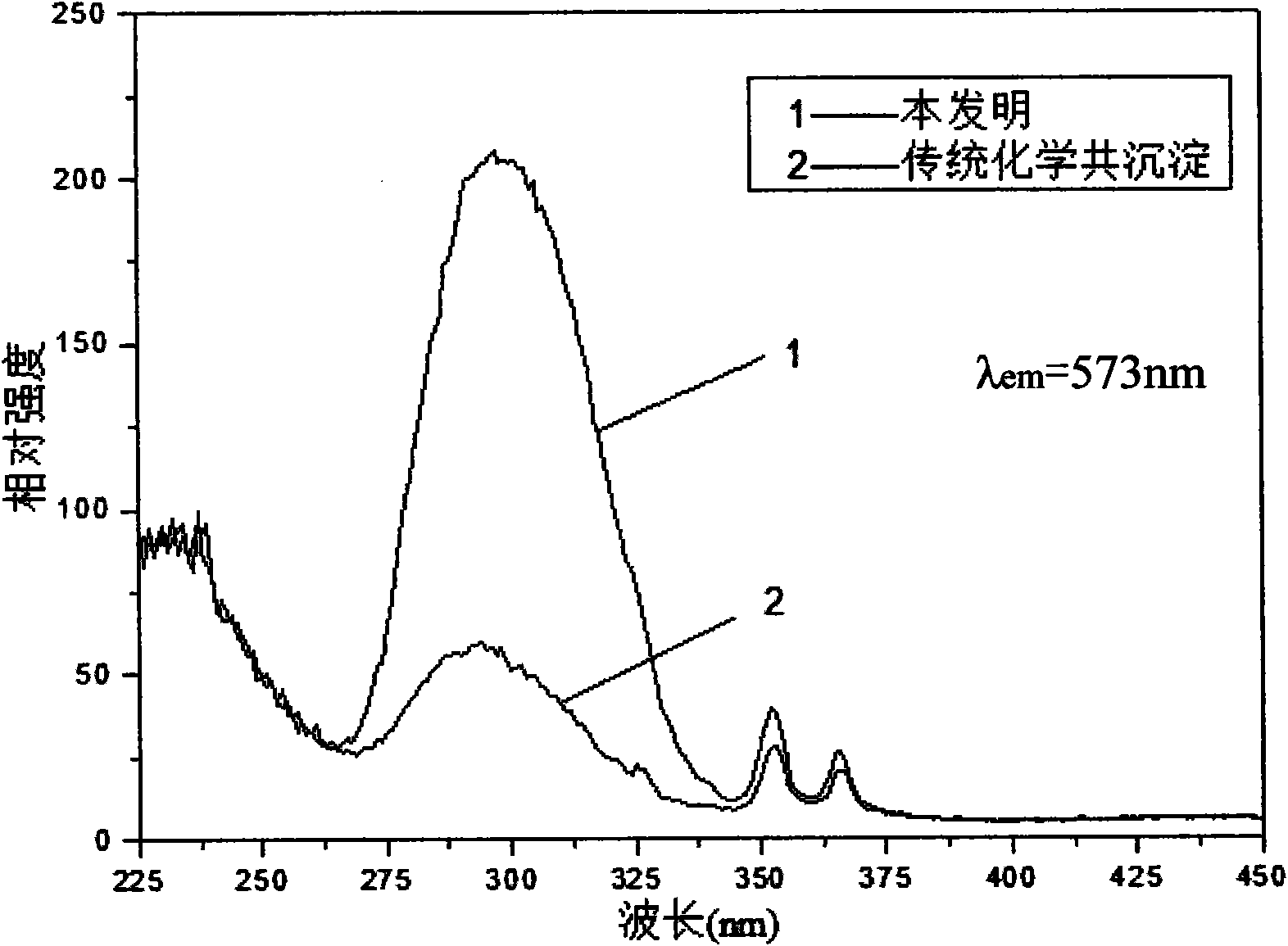

[0044] A kind of preparation YPO 4 : Dy 3+ (Single-phase multi-metal cationic phosphate) method of phosphor luminescent material:

[0045] Step 1, prepare raw materials and pH regulator:

[0046] YPO as prepared 4 : Dy 3+ The Y in the phosphate formula 3+ 、Dy 3+ and PO 4 3- The molar ratio of each weighs 1.12g of Y 2 o 3 , 0.019g Dy 2 o 3 and 1.32g (NH 4 ) 2 HPO 4 ; The pH regulator is urea;

[0047] Step 2,

[0048] 1.12g Y 2 o 3 , 0.019gDy 2 o 3 , 1.32g (NH 4 ) 2 HPO 4 After mixing evenly with 25g of urea, first add 25ml of concentrated nitric acid with a concentration of 69%, then add 40ml of water, fully dissolve the mixture with acid and water, and obtain a clear solution C with a solution temperature of 40°C and a pH value of 1;

[0049] Step 3,

[0050] Heating solution C at a heating temperature of 90°C and stirring continuously, after the complete reaction of urea, the pH value of solution C reaches 7, and then aging for 5 hours, after filterin...

Embodiment 2

[0058] A kind of preparation YPO 4 :Eu 3+ (Single-phase multi-metal cationic phosphate) method of phosphor luminescent material:

[0059] Step 1, prepare raw materials and pH regulator:

[0060] YPO as prepared 4 :Eu 3+ The Y in the phosphate formula 3+ 、Eu 3+ and PO 4 3- The molar ratio weighs 1.12g of Y 2 o 3 , 0.018g Eu 2 o 3 and 1.32g (NH 4 ) 2 HPO 4 ; The pH regulator is urea;

[0061] Step 2,

[0062] 1.12g Y 2 o 3 , 0.018g Eu 2 o 3 , 1.32g (NH 4 ) 2 HPO 4 After mixing evenly with 35g of urea, first add 15ml of concentrated nitric acid with a concentration of 69%, then add 60ml of water, fully dissolve the mixture with acid and water, and obtain a clear solution C with a solution temperature of 20°C and a pH value of 3;

[0063] Step 3,

[0064] Heating solution C at a heating temperature of 95°C and stirring continuously, after the complete reaction of urea, the pH value of solution C reaches 9, and then aging for 5 hours, after filtering, washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com