Device for cleaning and cooling glass surface of solar component

A technology for solar modules and glass surfaces, applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve problems such as lack of technical solution support, meet the requirements of time cleaning and cooling, significant economic benefits, and reduce operating temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

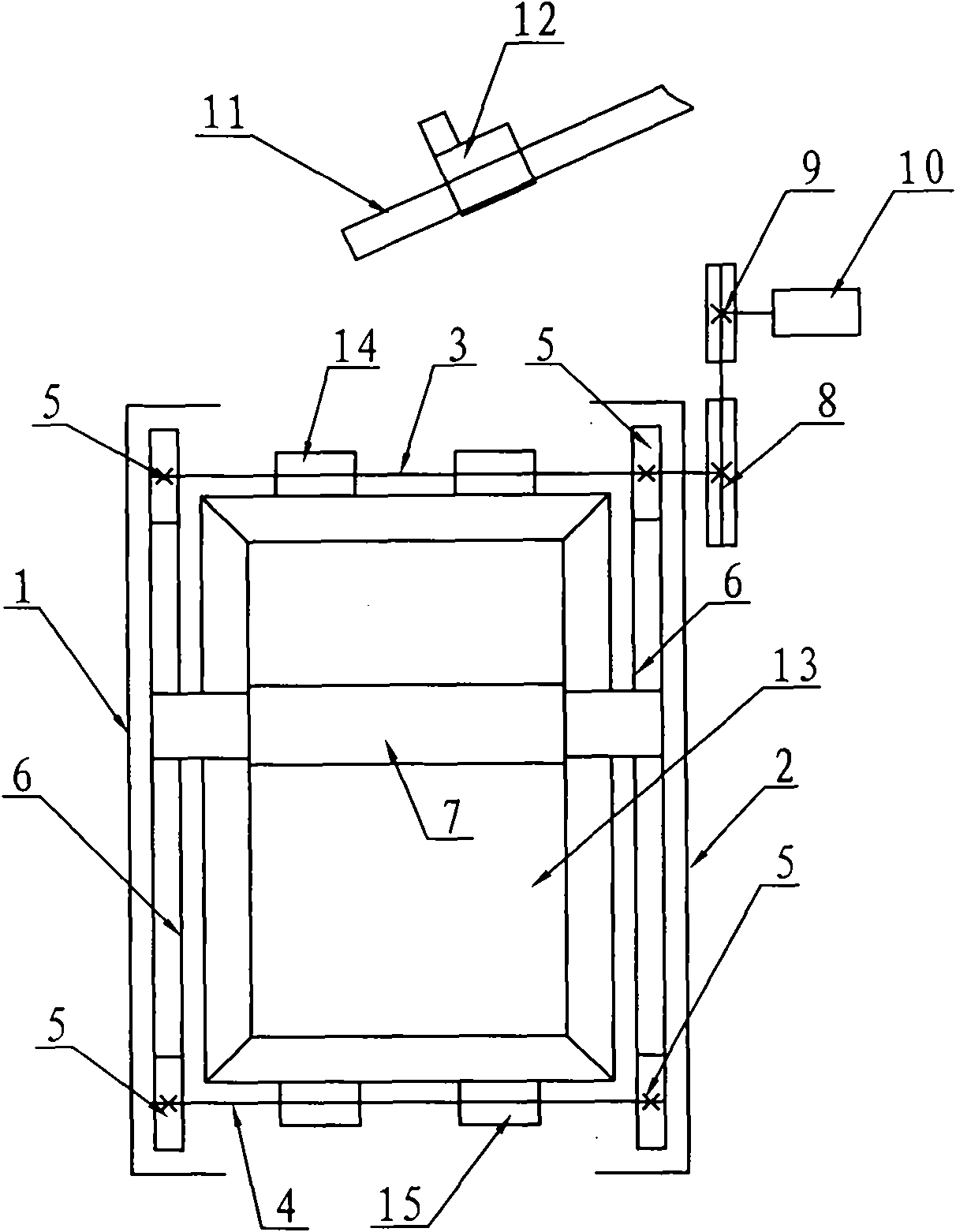

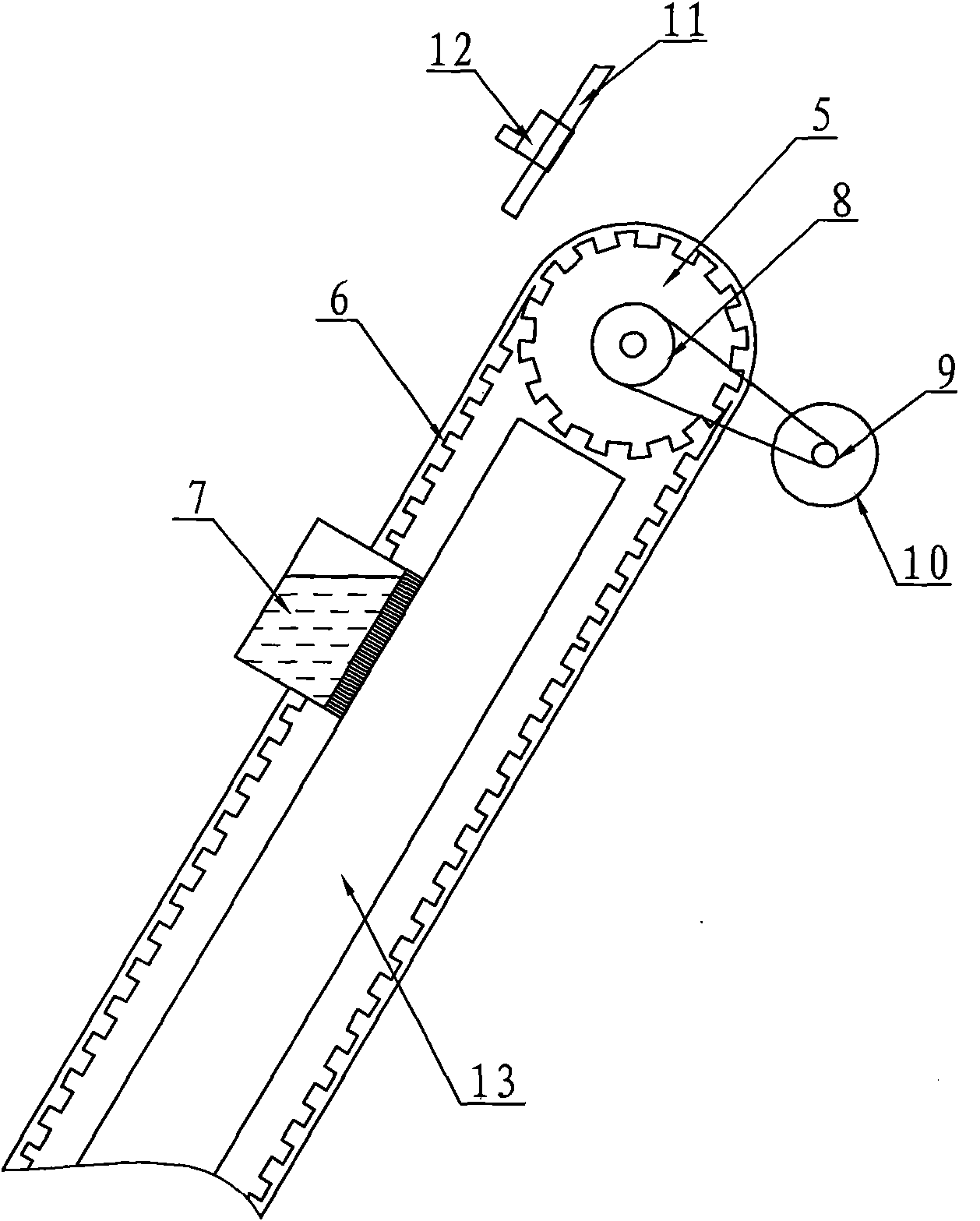

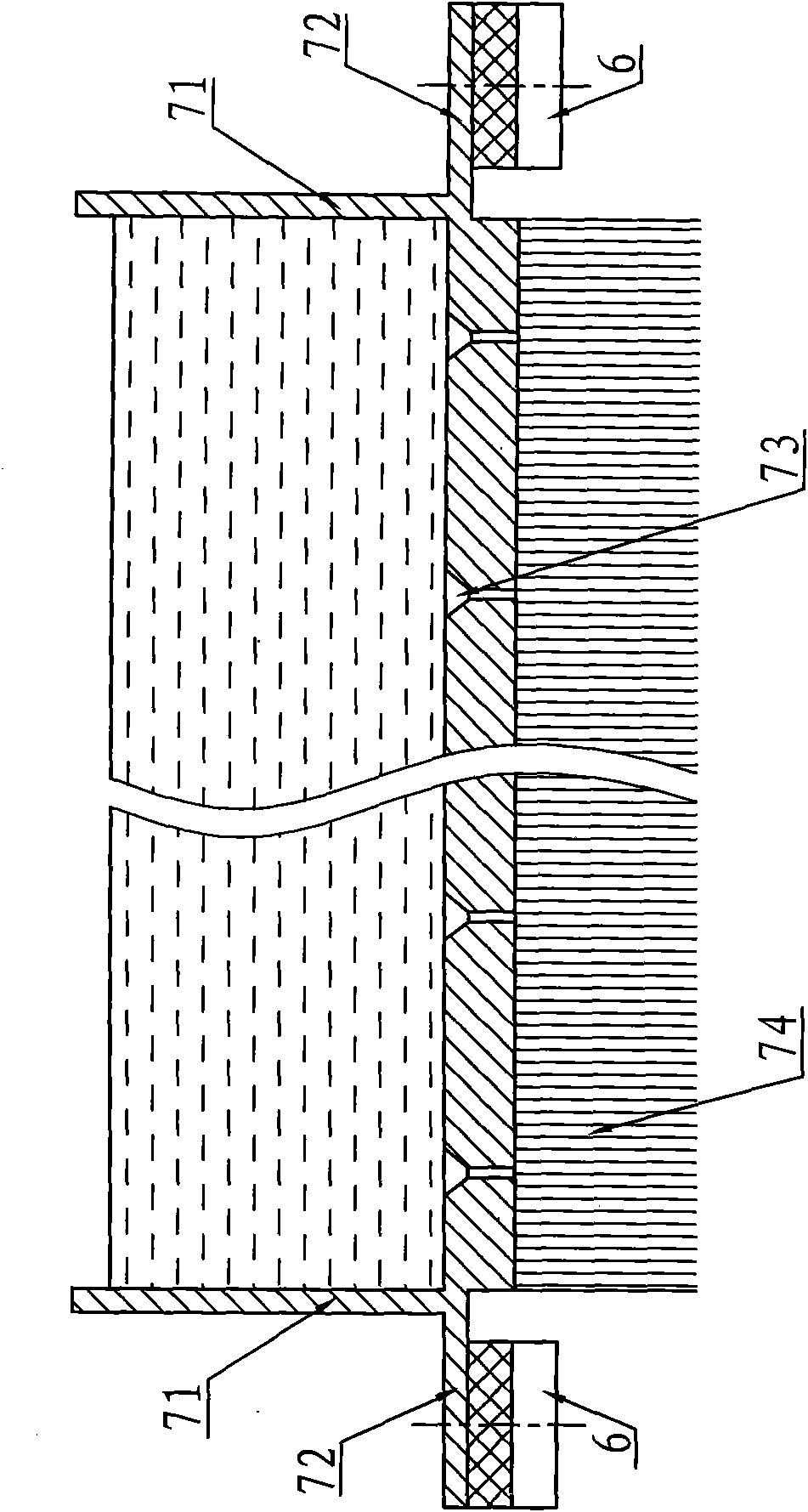

[0016] The solar module glass surface cleaning and cooling device, such as Figure 1 ~ Figure 3 As shown, it includes a left frame 1, a right frame 2, an upper main shaft 3, a lower main shaft 4, a synchronous pulley 5, a synchronous belt 6, a brush part 7, a driven wheel 8, a driving wheel 9, a DC motor 10, a water pipe 11, Solenoid valve 12, battery assembly 13, upper support block 14 and lower support block 15, left frame 1 and right frame 2 are respectively fixed on the left and right aluminum frames of battery assembly 13, upper spindle 3 is installed horizontally through two upper support blocks 14 On the upper frame of the battery assembly 13, the lower main shaft 4 is horizontally installed on the lower frame of the battery assembly 13 through two lower supporting blocks 15, and one identical synchronous Pulley 5, two synchronous pulleys 5 up and down on the left side are located in the left frame 1, and the two synchronous pulleys 5 in the left frame 1 are driven by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com