External heating internal coal decomposing equipment

An external heating, material technology, used in special forms of dry distillation, indirect heating dry distillation, petroleum industry and other directions, can solve the problems of increasing the cost of coal powder decomposition, the coal powder cannot be used directly, and cannot be uniformly heated, etc., so as to improve the utilization rate. and utilization level, saving and utilizing energy, and facilitating inspection and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

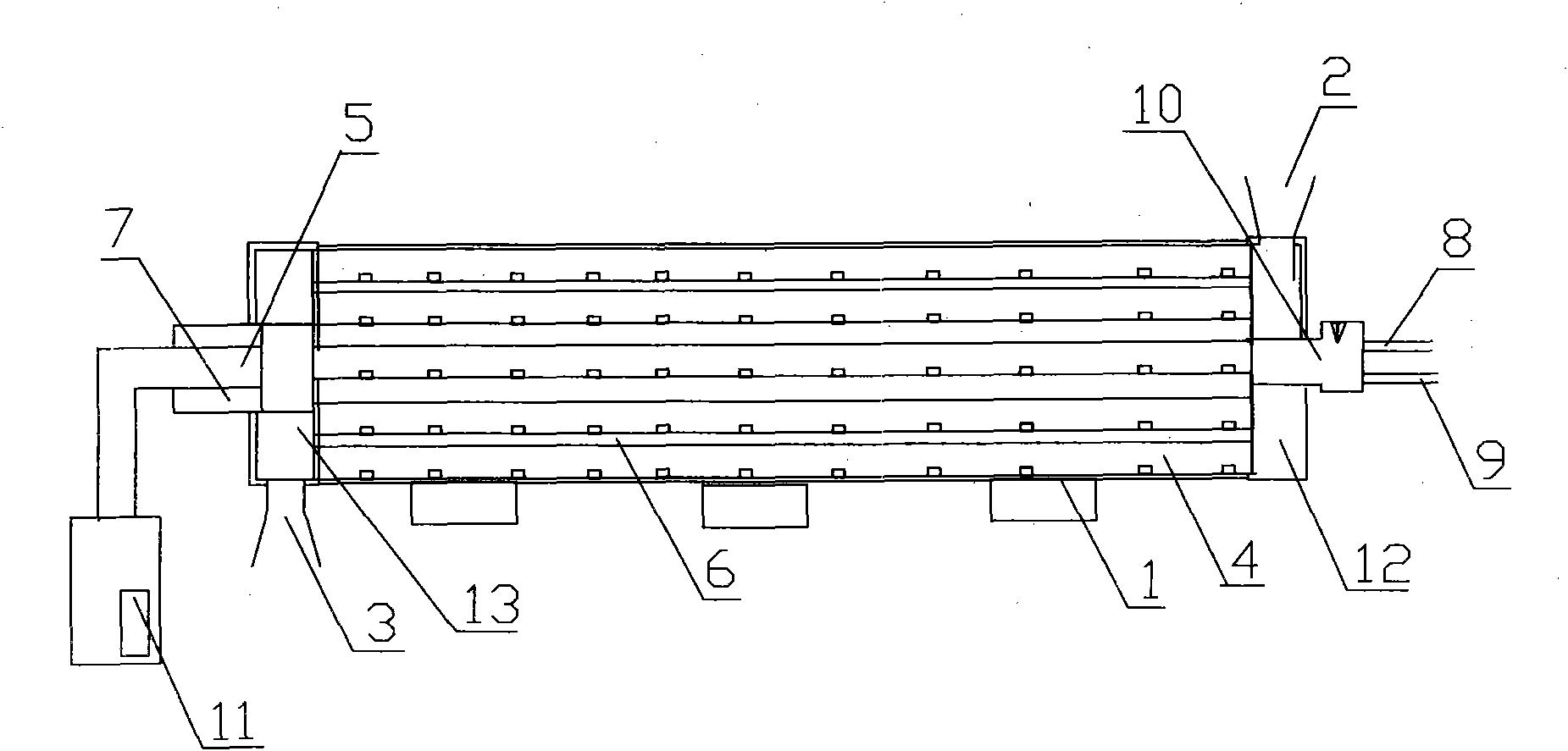

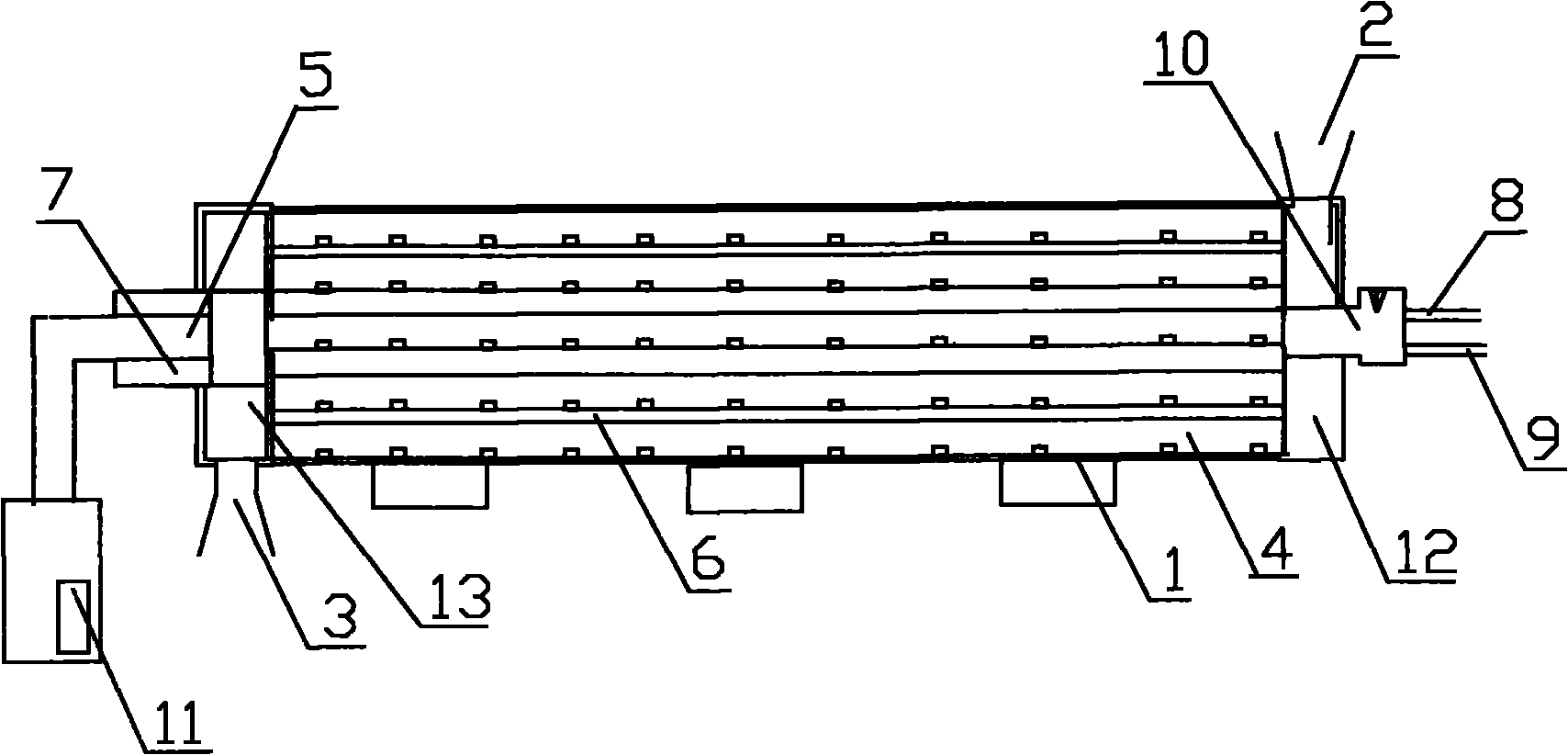

[0021] Such as figure 1 Shown: a kind of internal coal and external thermal coal decomposition equipment, including a sealed rotary kiln body 1, the coal substance propelling decomposition pipeline 4 is arranged in the kiln body 1, and the coal substance propelling decomposition pipeline 4 is provided with a coal inlet 2 , the coal outlet 3 and the decomposition gas collection pipe 5, a heat exchange chamber 6 is provided between the coal material propelling decomposition pipe 4 and the inner wall of the kiln body 1, and the heat exchange chamber 6 is provided with a heating gas outlet pipe 7. The high-temperature gas heating mechanism includes a fuel supply pipe 8 , an air supply pipe 9 and a combustion chamber 10 . The high-temperature gas heating mechanism is arranged outside the kiln body. The combustion chamber 10 communicates with the heat exchange chamber 6 . The decomposed gas collection pipe 5 is connected to a gas post-processing mechanism 11 arranged outside the k...

Embodiment 2

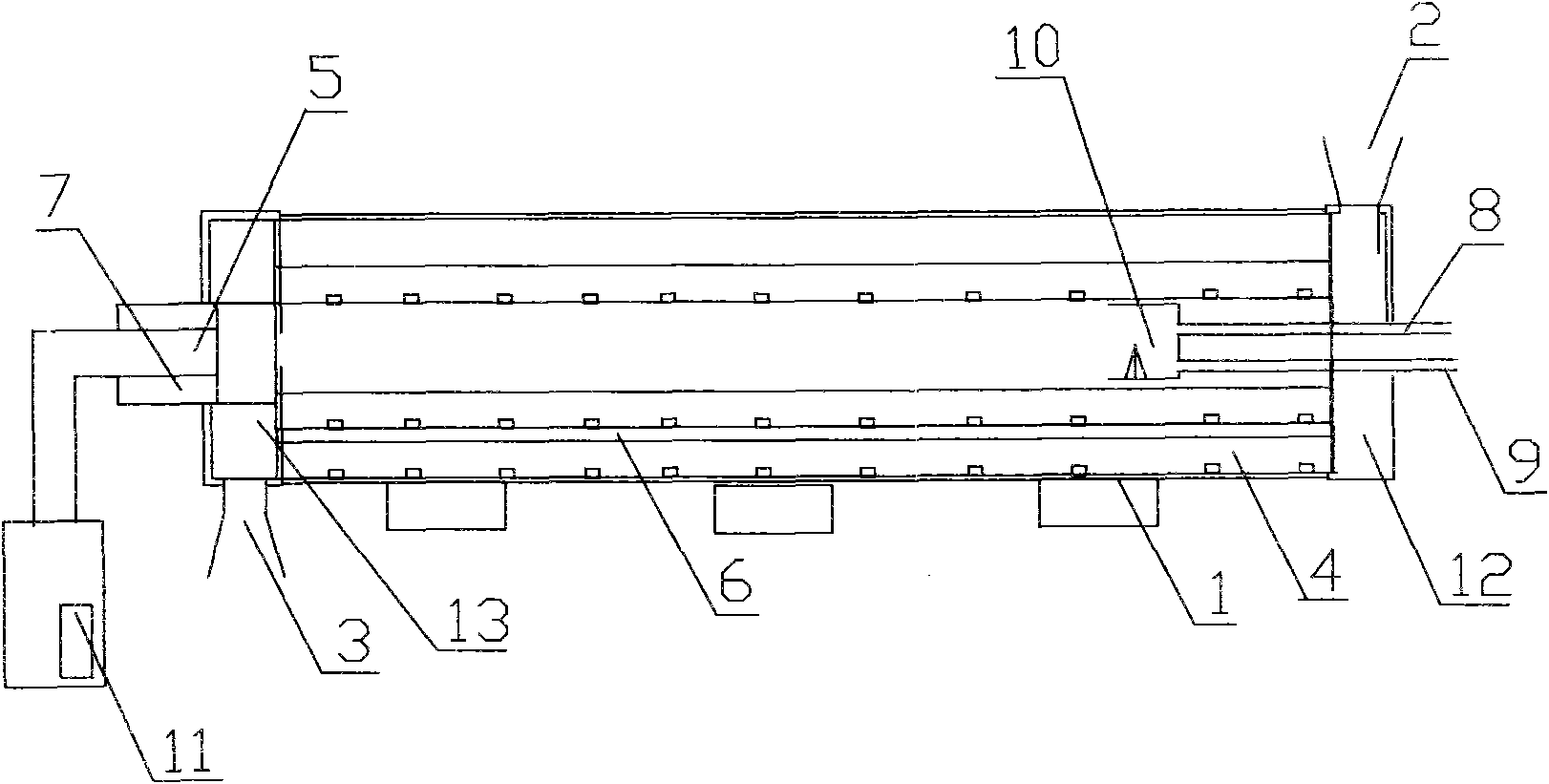

[0023] Such as figure 2 Shown: a kind of internal coal and external thermal coal decomposition equipment, including a sealed rotary kiln body 1, the coal substance propelling decomposition pipeline 4 is arranged in the kiln body 1, and the coal substance propelling decomposition pipeline 4 is provided with a coal inlet 2 , the coal outlet 3 and the decomposition gas collection pipe 5, a heat exchange chamber 6 is provided between the coal material propelling decomposition pipe 4 and the inner wall of the kiln body 1, and the heat exchange chamber 6 is provided with a heating gas outlet pipe 7. The high-temperature gas heating mechanism includes a fuel supply pipe 8 , an air supply pipe 9 and a combustion chamber 10 . The high-temperature gas heating mechanism is arranged inside the kiln body, the combustion chamber 10 communicates with the heat exchange chamber 6, and the fuel supply pipe 8 and the air supply pipe 9 extend out of the kiln body. The decomposed gas collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com