X-shaped link telescopic boom type hydraulic power engine and generator set device

A technology of hydraulic power and generator set, which is applied in the field of oil and power input, and can solve the problems of lengthening, depletion, energy supply, and increased cost of configuration components of the non-turnable connecting rod 25, so as to achieve ideal soft start or no-load Startup function, good load balancing ability, convenience and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

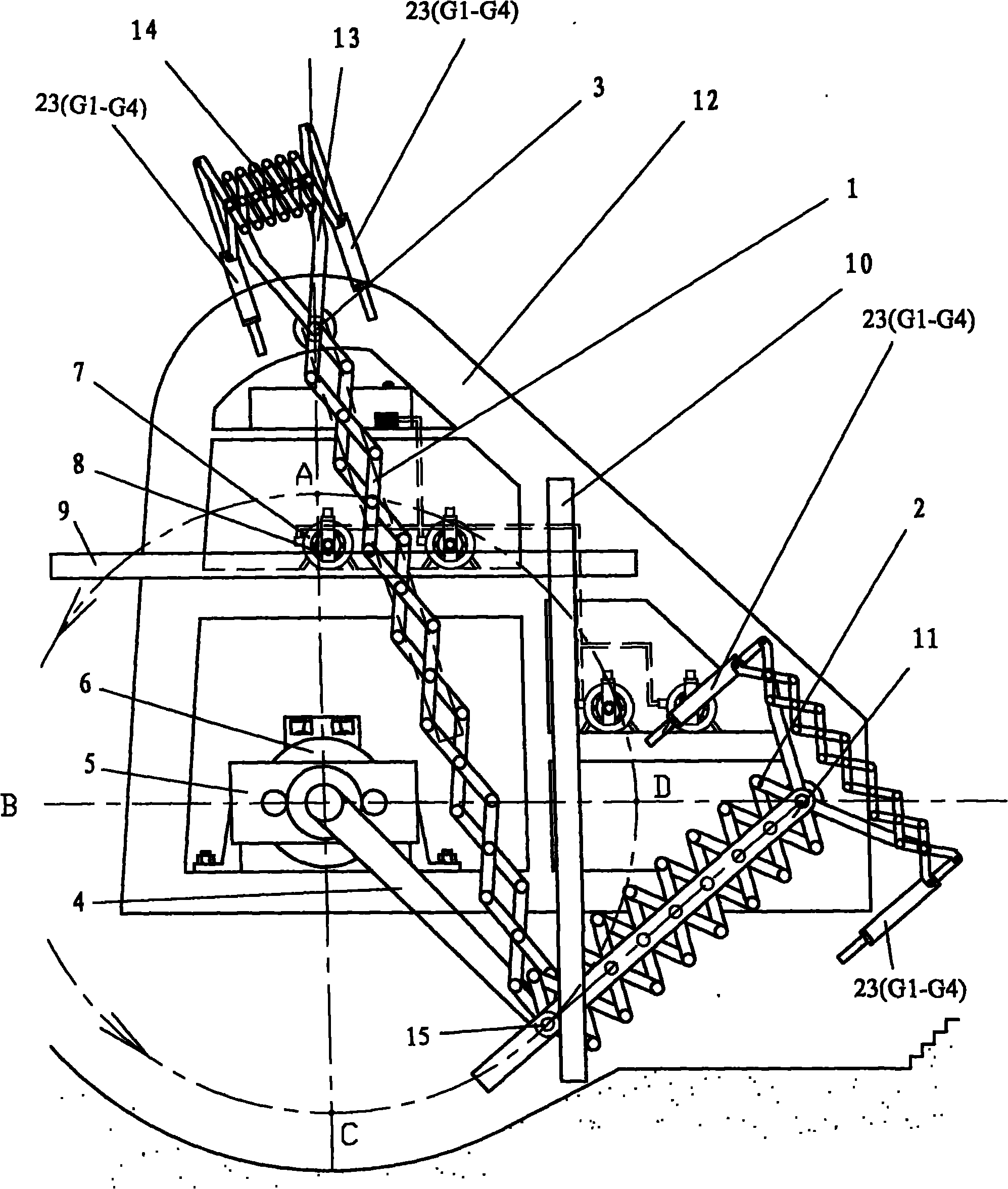

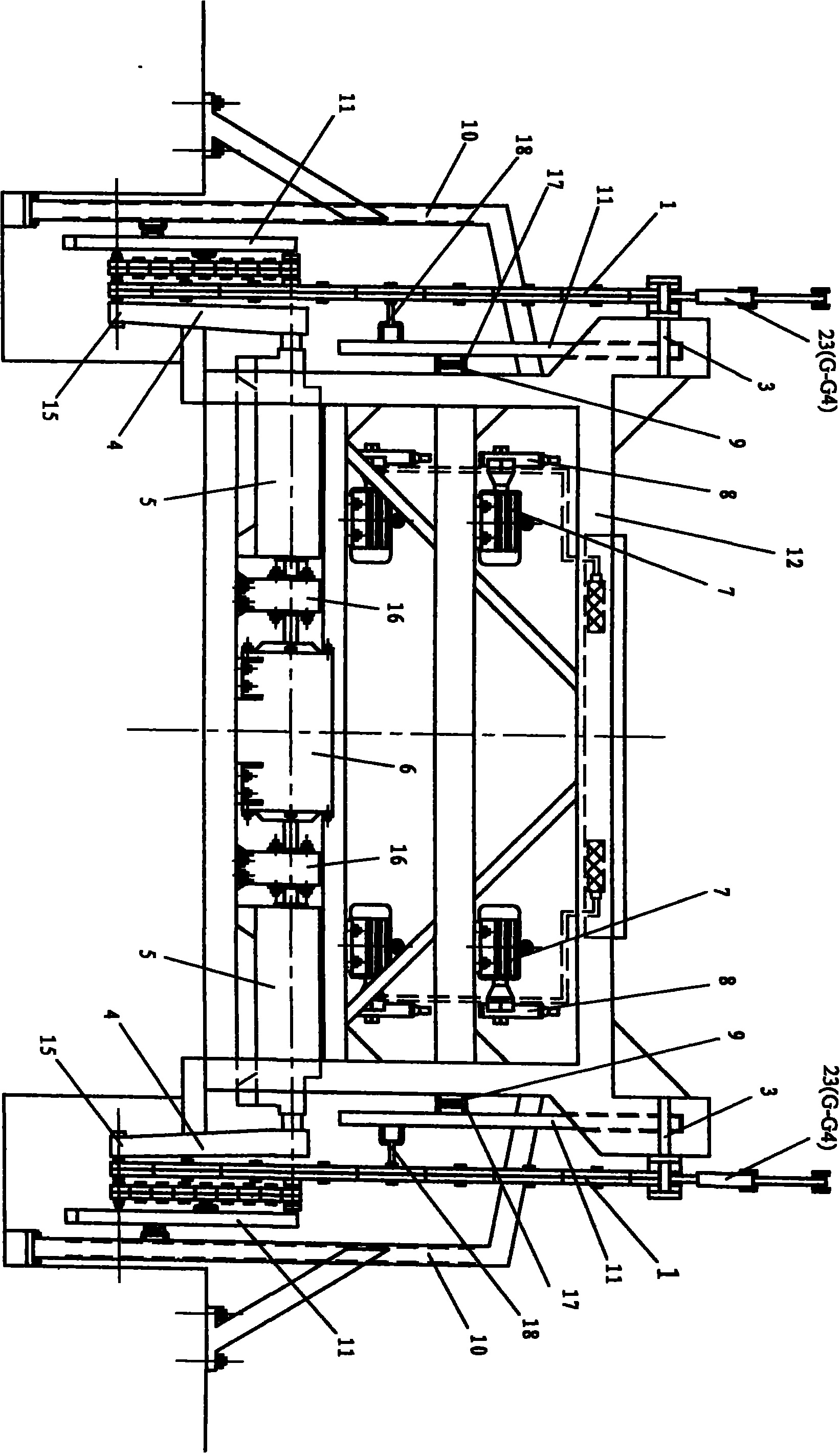

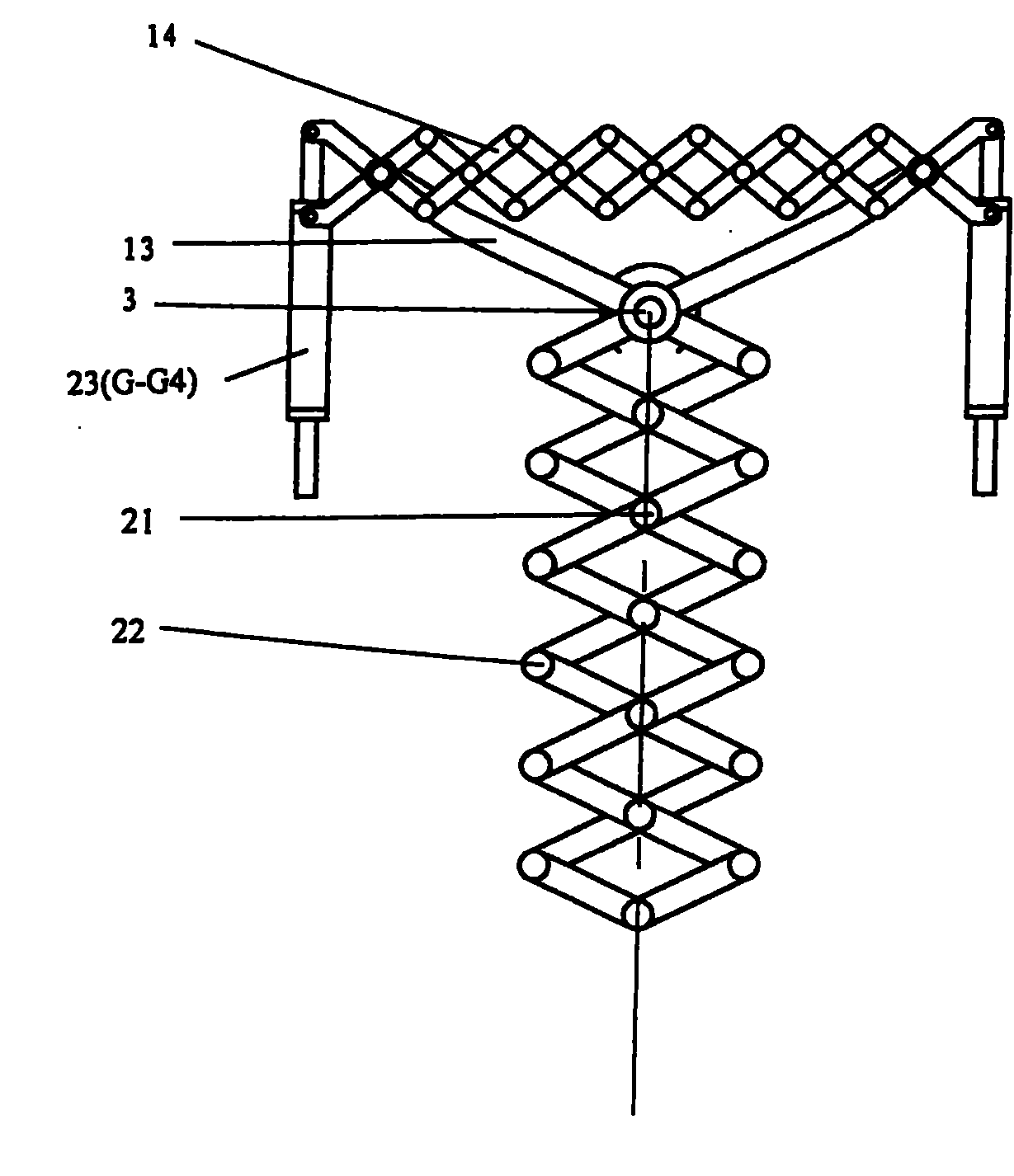

[0042] Below in conjunction with accompanying drawing, the present invention will be further described:

[0043] In Fig. 1, it mainly consists of group A booster type X-link telescopic arm 1, group B booster type X-type link telescopic arm 2, and hangs the fixed shaft with a beam frame at an angle of 90 degrees 3, and is fixedly connected to the gantry beam frame 12, on the power input end of the X-type link telescopic arm of group A and group B, the power input end other than the center point of the beam frame county hanging fixed shaft 3 is provided with an afterburner type power input rod 13, and a double input afterburner type is arranged at its top end. X-type link telescopic arm 14, a double-acting double-piston rod hydraulic cylinder (G1-G4) 23, the adjustable speed motor (2) 7, a hydraulic system hydraulic pump are respectively provided at the power input ends of the two ends. (4) 8. It is the main power source of the engine, which is the same as the principle of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com