Reactor and application thereof to hydrocarbon oil liquid-solid two-phase hydrogenation

A reactor and reaction technology, applied in the field of hydrocarbon oil liquid phase hydrogenation, can solve the problems of high investment, reduced catalyst activity and selectivity, etc., and achieve the effects of low investment, reduced reactor volume, and small hydrogen loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

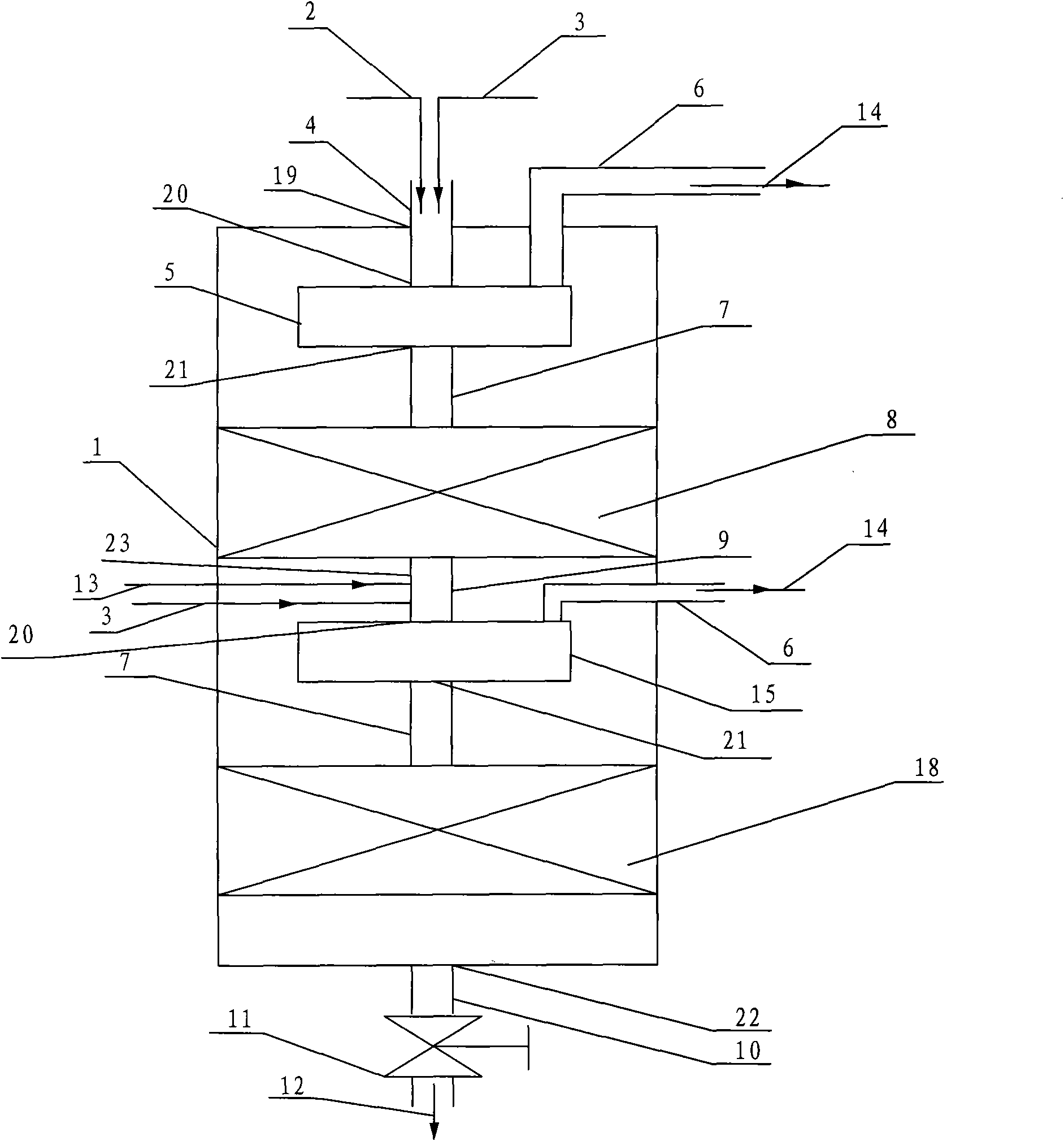

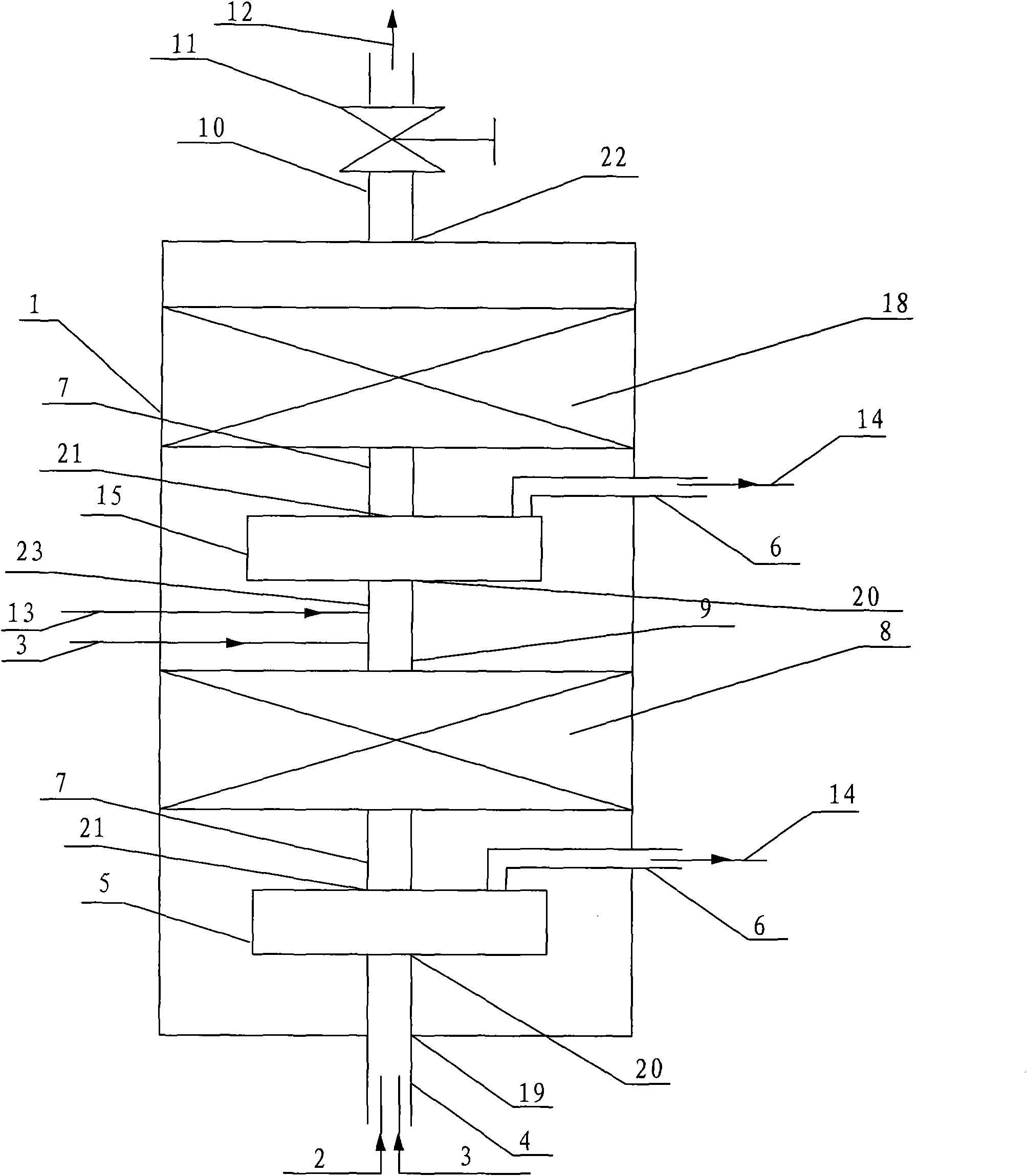

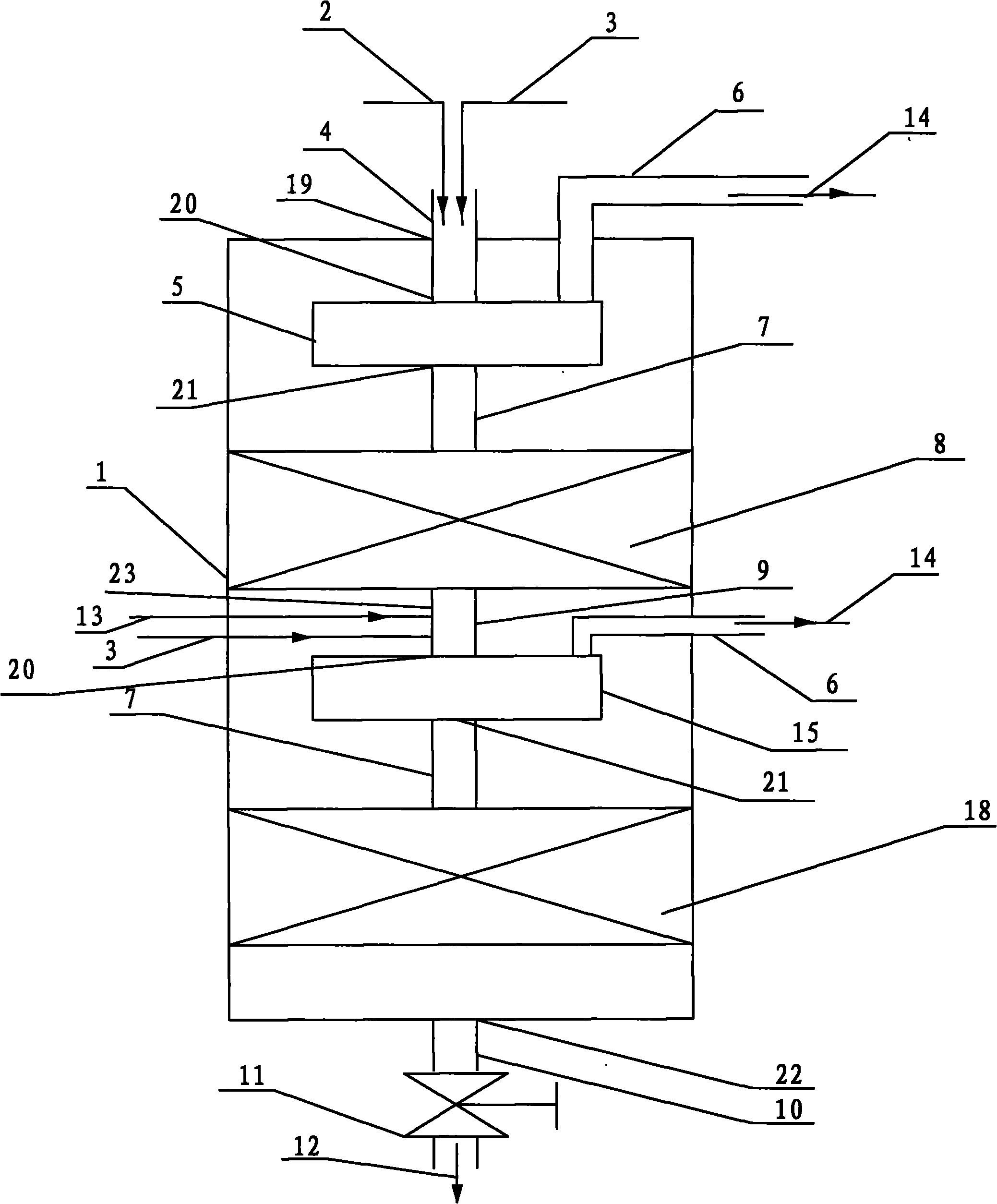

[0064] Such as figure 1 as shown, figure 1 For a reactor with two catalyst beds, the reactor inlet 19 is arranged at the top of the reactor. figure 1 The shown reactor comprises a reactor barrel 1 and two catalyst beds, namely a first catalyst bed 8 and a second catalyst bed 18, two mixers, namely a first mixer 5 and a second mixer 15, Wherein the first mixer 5 is arranged below the reactor inlet 19, the second mixer 15 is arranged between the first catalyst bed 8 and the second catalyst bed 18, and the first mixer 5 and the second mixer 15 are provided with Mixer inlet 20, hydrogen-dissolving mixture outlet 21 and gas outlet 6 are arranged, reactor inlet 19 is arranged on the top of the reactor and is connected with the mixer inlet 20 of first mixer 5 by connecting pipe 4, the first mixer 5 The hydrogen-dissolved mixture outlet 21 is connected to the first catalyst bed 8 through the connecting pipe 7, and the gas outlet 6 of the first mixer 5 extends to the outside of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com